-

-

August 10, 2023 at 12:24 pm

gazisamed

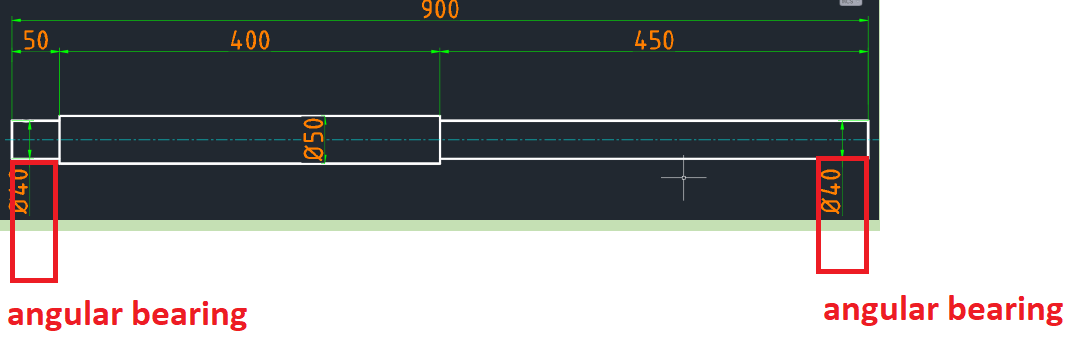

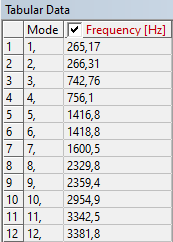

SubscriberWe performed an experimental modal analysis of a stepped shaft anchored from two sides. The results we obtained experimentally;

mode 1: 137,65

mode 2: 343.56

mode 3: 987.78

mode 4: 1431.61

mode 5: 2137.78

mode 6: 2984.98

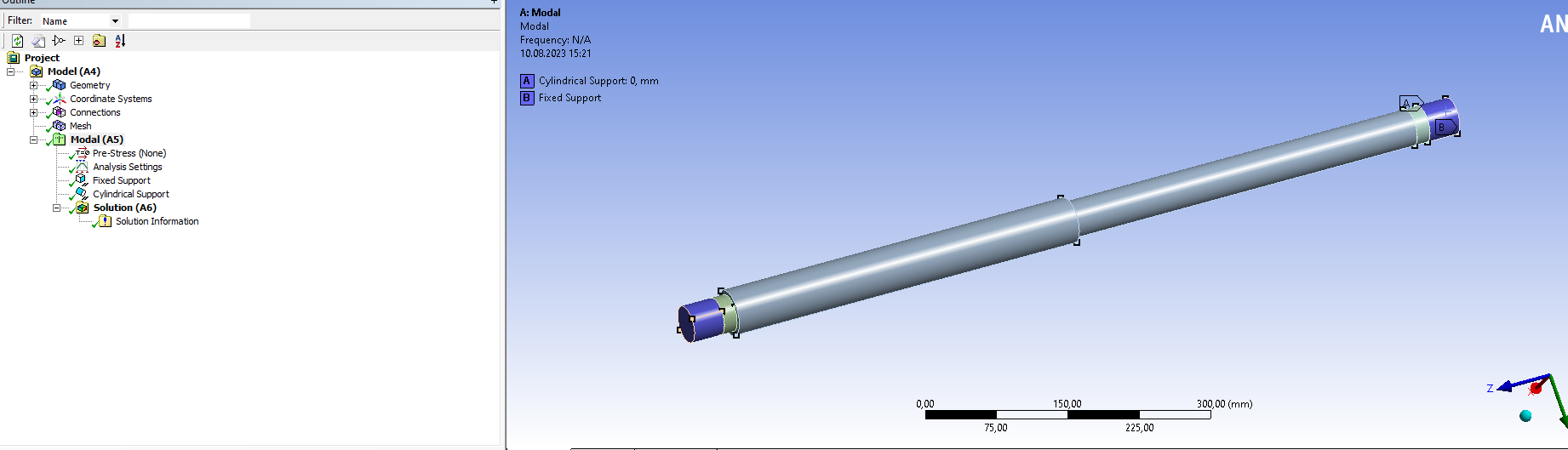

When I add fixed support from the insert section while doing modal analysis in the ansys program, the results are not the same as the experimental results.What should I do in ansys program to make the experimental results and ansys results equal.

material 1040 steel -

September 1, 2023 at 1:23 pm

Ashish Khemka

Forum ModeratorHi,

Please check for material property, geometry, and boundary conditions between test setup and simulation. Do you expect angular bearing to behave similarly to fixed support?

Regards,

Ashish Kumar

-

September 2, 2023 at 11:01 am

peteroznewman

Subscribergazisamed,

Fixed support + cylindrical support is much more stiff than the actual bearing stiffness so the first mode from Ansys model is higher than the experimental result.

Delete those supports and use a Remote Displacement on one end with X, Y, Z and Rotation about Z set to 0 while leaving Rotation about X and Y Free. Use another Remote Displacement at the other end with X and X set to 0 while leaving the other DOF Free. This support will be less stiff than the actual bearing stiffness so the first mode from Ansys should be lower than the experimental result.

Go to the bearing manufacturer’s website and search for the actual bearing stiffness values. When you have those, you can insert a Bearing support where the stiffness values from the manufacturer can be entered. Then the Ansys modes should be between the extreme cases I described above and closer to the experimental result. You can tune the stiffness values in the Ansys model to match the first mode of the experimental value.

-

- The topic ‘Modal Analysis’ is closed to new replies.

-

4934

-

1638

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.