TAGGED: ansys-ls-dyna, shear-stress, simulation-crash

-

-

June 8, 2023 at 12:30 pm

Noah

SubscriberHello,

I have a question/problem with a crash simulation of a simple pipe.

After a certain moment of deformation the following message appears:

Element deleted due to maximum shear 6.40633E+02 > tauc= 6.37500E+02

However, the program runs through without errors until the end.

When I then look at the result in the PrePost, however, no deleted elements are visible.

This only occurs with finer meshing; this error does not occur with coarser meshing.

What could be the reason for this?

Thanks a lot!

-

June 9, 2023 at 4:56 pm

Jim Day

Ansys EmployeeGenerally, the element ID would be given in the failure message. View that element by itself when postprocessing d3plot to confirm whether or not that element is actually removed from the display the the reported time of failure. I would also plot a time history of stress for the element to see what happens to stress at the time of reported failure. If you have any follow-up to this reply, please state what element formulation and what material model are used for the failed element(s). -

June 21, 2023 at 11:58 am

Noah

SubscriberThank you very much for your answer.

I use shell elements with the formulation ELFORM 16.

Thereby I use a SHELL NIP of 3.

As material model I use MAT_107 with the appropriate error parameters of Cockcroft-Latham.

Can it be that only the outer elements that are created based on the NIP command are deleted and not the nodes? -

June 21, 2023 at 3:23 pm

Jim Day

Ansys EmployeeTo what are you referring when you say "outer elements that are created based on the NIP command"? NIP is the number of through-thickness integration points for each shell element. When an element is deleted, any nodes that are freed up will generally remain in the simulation as unattached nodes. Those unattached, free nodes will no longer participate in the contact unless the variable ENMASS in *CONTROL_CONTACT is invoked. See description of ENMASS in the User's Manual. -

June 22, 2023 at 9:40 am

Noah

SubscriberThat was my wrong interpretation.

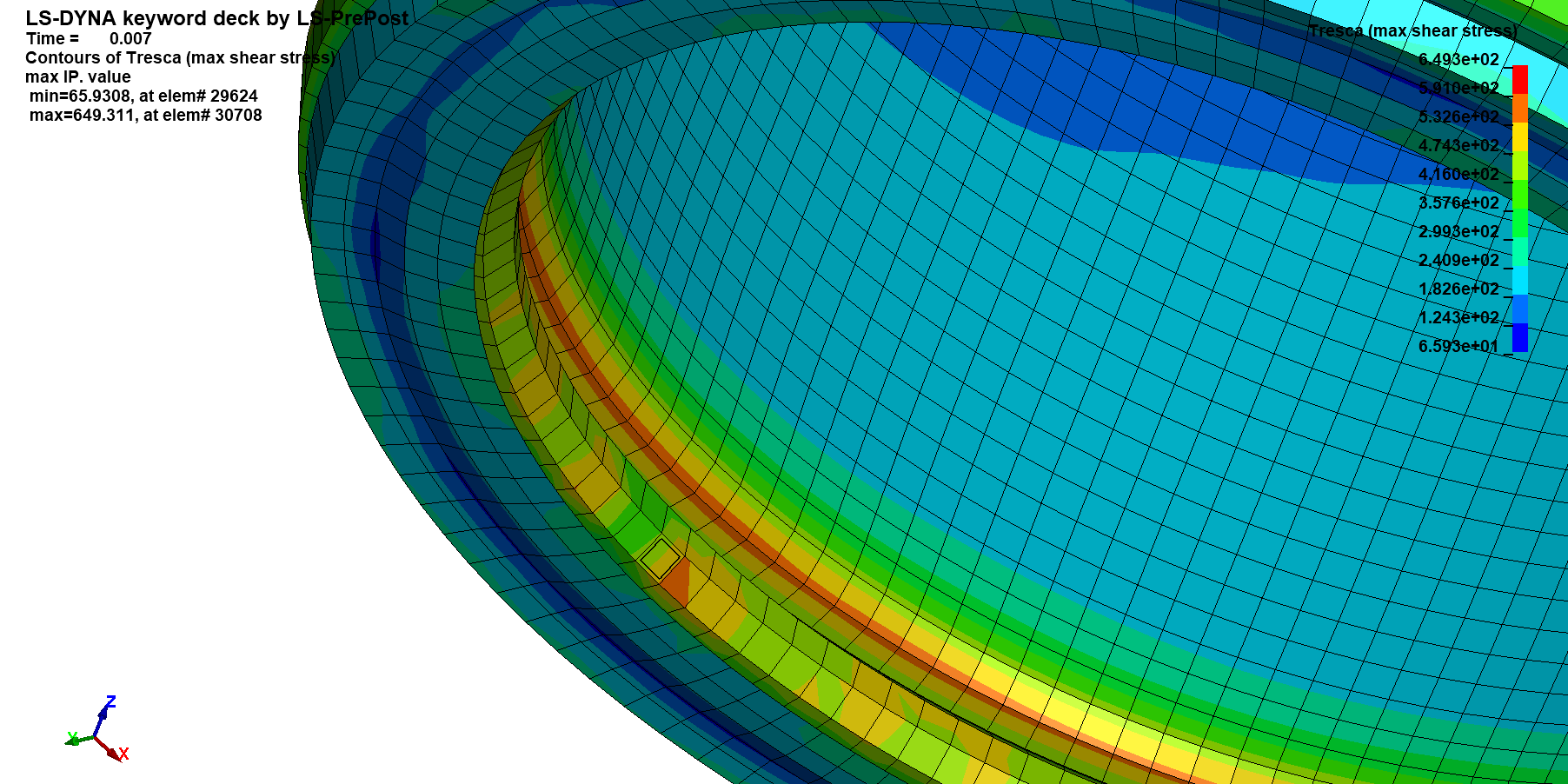

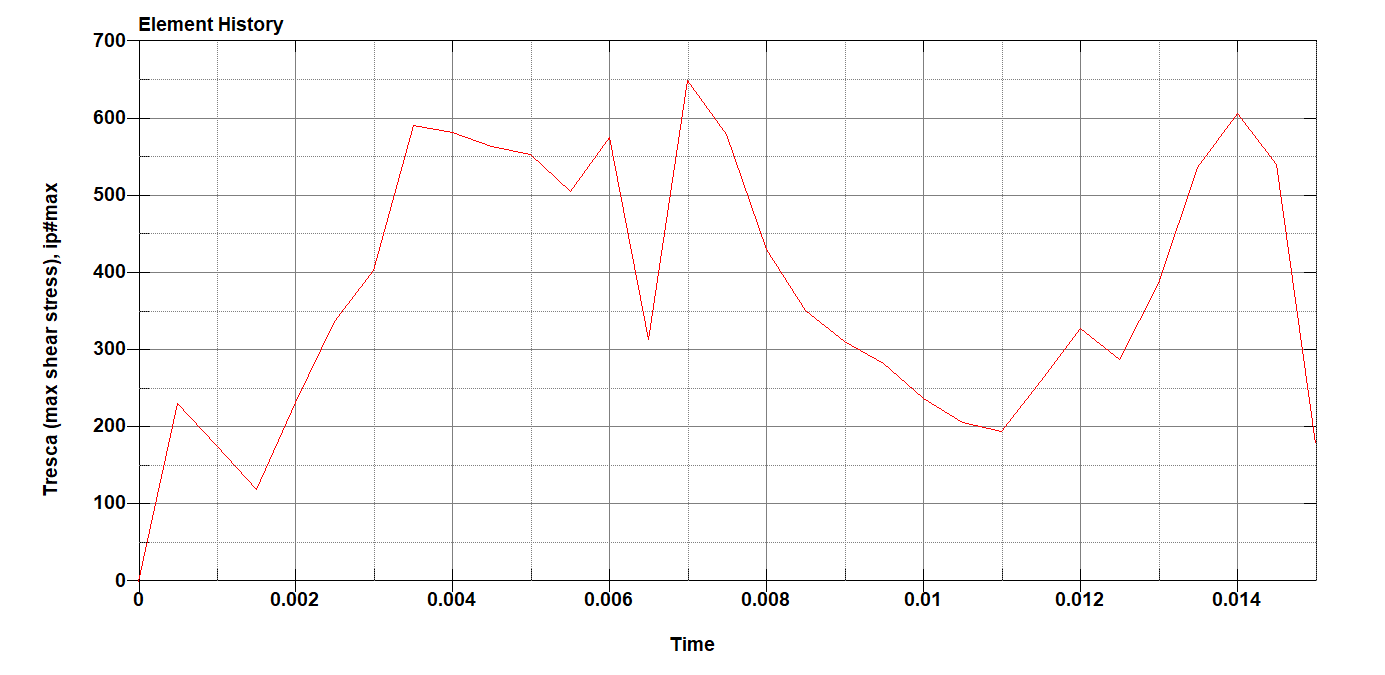

Attached is a picture of an element that exceeds the shear stress but is not deleted.

Also note the diagram where the element exceeds the maximum shear stress of 637.5 MPa.

What could be the reason for this?LS-DYNA keyword deck by LS-PrePost

*CONTROL_BULK_VISCOSITY

$# q1 q2 type btype tstype

1.5 0.06 -1 0 0

*CONTROL_HOURGLASS

$# ihq qh

8 0.03

*CONTROL_SHELL

$Shell Theory zurückgesetzt auf 02

$# wrpang esort irnxx istupd theory bwc miter proj

20.0 0 -1 0 2 2 1 0

*CONTROL_TERMINATION

$# endtim endcyc dtmin endeng endmas nosol

0.015 0 0.0 0.01.000000E8 0

*CONTROL_TIMESTEP

$# dtinit tssfac isdo tslimt dt2ms lctm erode ms1st

0.005 0.0 0 0.0 0.0 0 0 0

*DATABASE_NODOUT

$# dt binary lcur ioopt option1 option2

0.001 0 0 1 0.0 0

*DATABASE_RWFORC

$# dt binary lcur ioopt

0.001 0 0 1

*DATABASE_BINARY_D3PLOT

$# dt lcdt beam npltc psetid

5.00000E-4 0 0 0 0

$# ioopt rate cutoff window type pset

0 0 0

*CONTACT_AUTOMATIC_SINGLE_SURFACE

$# cid title

$# surfa surfb surfatyp surfbtyp saboxid sbboxid sapr sbpr

3 3 0 0 0

$# fs fd dc vc vdc penchk bt dt

0.2 0.18 0.0 0.0 0.0 0.01.00000E20

$# sfsa sfsb sast sbst sfsat sfsbt fsf vsf

1.5 1.0 1.0 1.0 1.0 1.0

$# soft sofscl lcidab maxpar sbopt depth bsort frcfrq

1 0.1 0 1.025 2.0 2 0 1

$# penmax thkopt shlthk snlog isym i2d3d sldthk sldstf

0.0 1 2 0 0 0 0.0 0.0

$# igap ignore dprfac dtstif unused unused flangl cid_rcf

1 1 0.0 0.0 0.0 0

*MAT_MODIFIED_JOHNSON_COOK_TITLE

MAT_107_V2A

$# mid ro e pr beta xsi cp alpha

17.90000E-9 200000.0 0.3 1.0 0.95.000000E81.60000E-5

$# e0dot tr tm t0 flag1 flag2

1.0 293.0 1673.0 293.0 0.0 1.0

$# a/siga b/b n/beta0 c/beta1 m/na

310.0 1000.0 0.65 0.007 1.0

$# q1/a c1/n q2/alpha0 c2/alpha1

$# dc/dc pd/wc d1/na d2/na d3/na d4/na d5/na

1.0 150.0

$# tc tauc

637.5

*PART

$# title

Tube_40x1_5

$# pid secid mid eosid hgid grav adpopt tmid

3 1 1 0 0 0 0 0

*SECTION_SHELL_TITLE

Shell_1_5

$# secid elform shrf nip propt qr/irid icomp setyp

1 16 0.8333333 3 1.0 0 0 1

$# t1 t2 t3 t4 nloc marea idof edgset

1.5 1.5 1.5 1.5 0.0 0.0 0.0 0 -

June 22, 2023 at 2:42 pm

Jim Day

Ansys EmployeeSet NEIPS to 9 and MAXINT=-3 in *DATABASE_EXTENT_BINARY. You should then be able to plot D, T, and taumax for all integrations points via history variables 1, 4, and 9, respectively. Those are the values to monitor to see if erosion criteria are met. Offhand, I'm not seeing in the User's Manual where it states the number of integration points that must reach the failure condition to trigger element erosion. Since there doesn't seem to be a variable that allows you to specify that number, the assumption would be either 1 integration point or all integration points. I'm not certain which it is. -

June 29, 2023 at 3:04 pm

Noah

SubscriberThank you, this has helped me a lot.

-

- The topic ‘LS-Dyna Tube Crash Simulation – message file’ is closed to new replies.

-

4838

-

1587

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.