TAGGED: fsi

-

-

November 8, 2022 at 2:18 pm

s.m.mousavi

SubscriberHi!

It's been a while since I've tried to simulate the blood flow pathing through the human aortic valve. I am trying to couple the Transient structural module with the Fluent via a Coupling system. However, I received either a "highly distorted element" error or "negative cell volume detected" in almost all the cases. To resolve the issues, I have tried:

1- refining the mesh in both structural and fluent modules;

2- reducing the system coupling time step.

I could not yet, however, get a converged solution. Can anyone please tell me any suggestions or advice?

I can provide more detail if necessary.

Thanks! -

November 10, 2022 at 1:52 pm

Rahul

Ansys EmployeeHi,

This error may occur when unreasonable displacements were received by fluent or unreasonable forces were sent to Mechanical APDL.

Using under-relaxation on the data transfers can help here. This will make the solution more stable

at the expense of more coupling iterations to reach convergence. Note that some cases can

remain unstable even when under-relaxation is used, to stabilize these types of cases Solution

Stabilization is available in Fluent in the Dynamic Mesh settings on the Solver Options panel.It is very important to build up the FSI simulation in stages as opposed to setting up the 2-way FSI right at the start. This document "Best Practices for Coupled Fluid-Structure Interaction (FSI)" describes this process and is available here: https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v221/en/sysc_ug/sysc_bestpractices_fsi.html

Hope this helps!

-

November 11, 2022 at 8:14 am

s.m.mousavi

SubscriberThank you, Rahul, for your valuable suggestions. I have tried both "under relaxation" and "stabilization" techniques. The simulation, however, is still unable to converge to any solution.

I would love to read "Best Practices for Coupled Fluid-Structure Interaction (FSI)", however, it seems I do not have access to them. Out of curiosity, is it possible to get them via email?

Thanks!

-

-

November 11, 2022 at 9:11 am

Rahul

Ansys EmployeeHi,

Please share the settings used to setup the project.

To diagnose the issue have a look at the system coupling log file (scLog.scl), fluent log file (.trn) and mechanical log file (.out)

Best practices can be found in system coupling manual. Best Practices for Coupled Fluid-Structure Interaction (FSI) (ansys.com)

-

November 11, 2022 at 11:01 am

s.m.mousavi

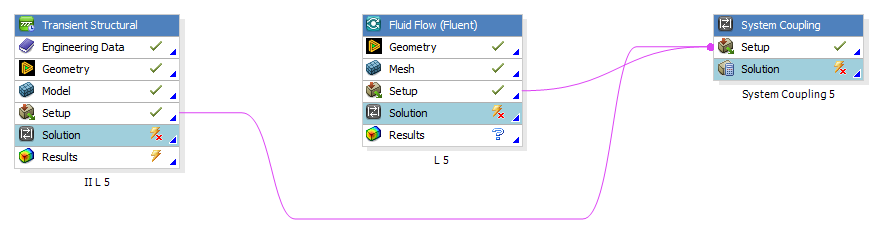

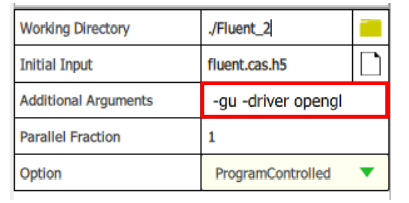

SubscriberI am stimulating the blood flow in the human aorta passing through the aortic valve. The computational domain is twofold: 1- aortic valve structural model (flexible), 2- flow of blood in aorta (with rigid walls). Below are the settings used to setup the project.

1- Aortic valve model in transient structural model:

· Linear elastic material with Young’s modulus of 1-2 e+06 [Pa] and Poisson’s ratio of 0.45.

· Linear/nonlinear Hex/tetrahedron elements.

· Fixed support at the base ring of the aortic valve.

· Compression only support at the inner surfaces of the aortic valve leaflets to prevent them penetrating each other.

· System Coupling Region at the surfaces of the aortic valve leaflets.

· Time step 0.005 [s]

2- Blood flow in Fluent:

· Linear Tetrahedron mesh.

· Transient, time step 0.005 [s]

· Viscous flow 0.0035 [kg/(m.s)], Density of 1060 [kg/m^3].

· One inlet pressure boundary condition, and three outlet pressure boundary conditions.

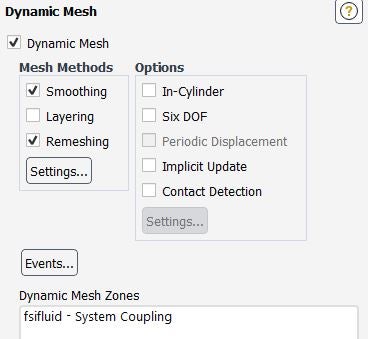

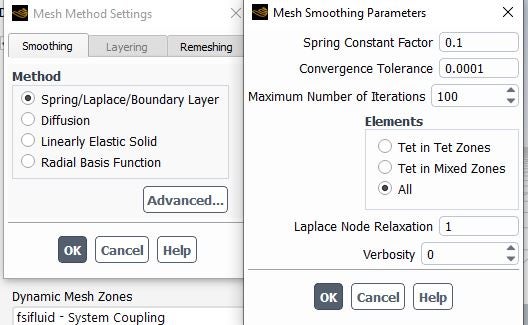

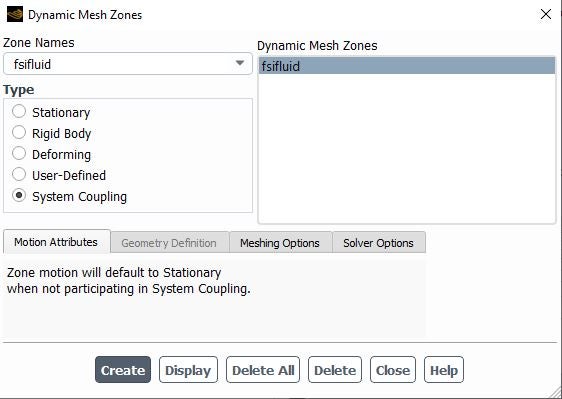

· Dynamic mesh to the fluid structure interaction surfaces: Smoothing (Spring), and Remeshing.

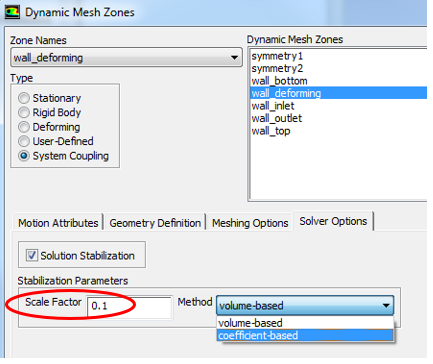

· System coupling, with(out) Solution Stabilization

3- System coupling

· Time step 0.005 [s], total time 0.85 [s]

· Under relaxation 1 or less

I can only get a converged solution when I am applying a high elasticity modulus (say 5-10 e 06 [Pa]), where the aortic valve movements are very small and not realistic.

I can provide more detail/photos if necessary. Please let me know.

Thank you!

-

-

November 11, 2022 at 11:19 am

Rahul

Ansys EmployeeHi,

Usually aortic flow is challenging simulation because they can be unstable. Try with more underrealxation or ramp up the load with 'ramping' option. Please share the Dynamic mesh settings.

Regards,

-

November 11, 2022 at 12:28 pm

s.m.mousavi

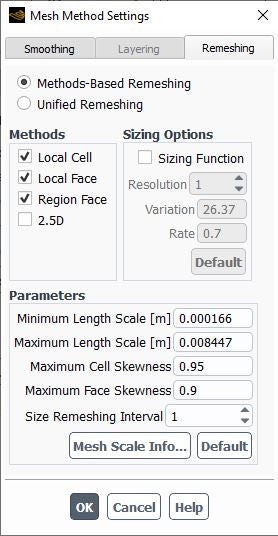

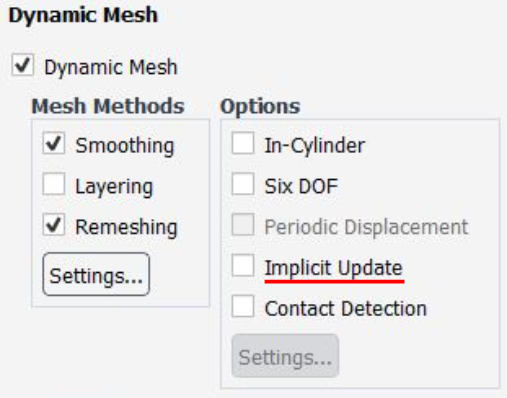

Subscriber1- The dynamic mesh settings are Smoothing and Remeshing:

2- I can change the "Ramping" on System Coupling from None to Linear to Minimum Iterations. However, it changed to a yellow field with a question mark close to the Data Transfer icon (such that something is incomplete).

3- I have tried Under relaxation up to 0.35. But it could not help me to get a converged solution.

-

-

November 11, 2022 at 1:57 pm

Rahul

Ansys EmployeeHi,

There are number of parameter that influence convergence. such as initialization, time step size, stability controls, number of fluent iterations per step, number of coupling iterations, interface URF , type of data trenafer.

Before changing inputs it is important to understand why solution has convergence problem. For that have a look at the log files for participating solvers and system coupling.

Please try changing smoothing to diffusion based smoothing and use 'unified remeshing' option. Keep solution stabilization enabled.

-

November 11, 2022 at 2:55 pm

s.m.mousavi

SubscriberIt has been almost one year since I am dealing with this FSI simulation. I have tried all of the Dynamic mesh types (smoothing, spring,...) with many different time step sizes, mesh configurations, under relaxation factors, number of coupling iterations, and so on. The only way I could get a converged FSI solution was when I am assigning a high elasticity value to the aortic valve. In fact, I am making it more rigid and the valve leaflets' movements are too tiny and far away from physiological values.

I copy paste the errors from the log files from some of my previous simulations:

sclog.scl: Participant Solution 18 encountered a fatal error. Message: Solution not |

| converged at time 5.5E-02 (load step 11 substep 1). Run terminated.Solution.trn: Participant Solution 18 encountered a fatal error. Message: Solution not converged at time 5.5E-02 (load step 11 substep 1). Run terminated.

Writing to DESKTOP-4C0P3TO:"D:\13 Numerical Simulations\...\dp0\FFF-6\Fluent\FFF-6.1-1-00011.cas.h5" in NODE0 mode and compression level 1 ...

Writing mesh ...

70614 cells, 1 zone ...

147532 faces, 7 zones ...

15161 nodes, 1 zone ...

Done.Solve.out: *** ERROR *** CP = 139.500 TIME= 20:46:59

Solution not converged at time 5.5E-02 (load step 11 substep 1).

Run terminated. -

November 15, 2022 at 9:54 am

-

-

November 15, 2022 at 10:03 am

Rahul

Ansys EmployeeHi,

Please export the system coupling files and try it in standalone system coupling with Quasi-Newton stabilization (i-QN). It will improve the stability of the solution and improve convergence.

Quasi-Newton stabilization is not supported for System Coupling in Workbench. To apply stabilization to a coupled analysis created in Workbench, export the coupling setup so the analysis can be executed in System Coupling's GUI or CLI.

Please refer Quasi-Newton Stabilization Algorithm (ansys.com) for more information.

-

November 15, 2022 at 12:20 pm

-

-

November 15, 2022 at 12:24 pm

Rahul

Ansys EmployeeHi,

To diagnose the issue have a look at the system coupling log file (scLog.scl), fluent log file (.trn) and mechanical log file (.out). Check the error encountered in Solution 6 and change inputs accordingly in WB and run in standalone SyC with newly exported files.

-

November 15, 2022 at 12:36 pm

-

-

November 15, 2022 at 12:53 pm

Rahul

Ansys EmployeeHi,

Looks like Fluent solution is not converging. Please try with lowering URF and time step size.

This type of problems are very nonlinear due to material property itself so it will require many fine tuning on set up to converge the case. I would recommend you to test only Fluent part and structure part separately with representative loads. This will help you to get best set up to be used in FSI . Please make sure standalone physics works fine before we run SyC case .

-

November 15, 2022 at 2:45 pm

s.m.mousavi

SubscriberThanks for your reply.

Compared to the previous simulation, I decreased the time step size from 0.005[s] to 0.0017[s], and URF from 1 to 0.5. Again, the solver failed to converge, surprisingly aborted even sooner than the previous model (with larger time step size and URF=1).

sclog.scl:

.trn:

.out:

I can successfully run the Structural model and the Fluent one separately. However, my problem for almost one year is when I am coupling them to run the FSI simulation (in fact, I have already applied many different suggestions to my problem).

By any chance, do you think we can have a meeting to better study the issue? I can involve my advisory team in further contacts and communications. We are located at Marche Polytechnic University in Italy. Please let me know.

-

-

November 21, 2022 at 5:59 am

Rahul

Ansys EmployeeHi,

Also try with enabling 'Implicit Update' option.11.6.6. Implicit Update Settings (ansys.com)

Let me know if that helps!

-

November 26, 2022 at 9:08 am

s.m.mousavi

SubscriberHi! I have replied to your post several days ago. Today I realized my answer has not been submitted for some unknown reasons. I have tried Implicit Update, however, still, my solution cannot be converged.

-

-

November 28, 2022 at 8:59 am

Rahul

Ansys EmployeeHi,

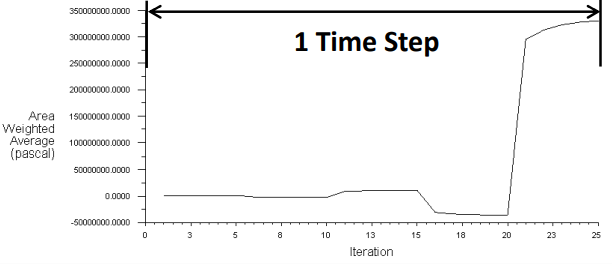

Case involving thin structures (sheet metal, membranes, etc), structural materials with low youngs modulus are typically unstable. To identify the instability you can monitor pressure/force convergence for FSI surfaces within each time step, which will help you to identify if the case is about to 'blow up' (Oscillation within time step) or you have achieved a good and stable convergence. Solution may be instable due to poor initialization.

Keep 'Solution Stabilization' enabled, it will slow down the pressure response in ANSYS Fluent at the deforming wall. Here higher sacle factor results in more stabilization (Start with low value and increase gradually)

Ensure that individual participant solution (e.g. Fluent alone) converges well.

Look at the residuals, which equation is causing convergence issue. Tune in the parameters related to that equation.Please refer to Improving Coupled Analysis Stability (ansys.com) for more information.

-

December 1, 2022 at 4:09 pm

-

August 13, 2023 at 4:58 pm

fares abbara

SubscriberHello, I am performing a blood flow FSI in the carotid artery and i have been having similar issues to the gentleman who started this thread. My model is less complicated with just a 6 cm elastic tube with young's modulus of 0.108MPa and poissson ratio of 0.49. The viscosity model is similar to this case. My boundary conditions are a bit different with outlet pressure set at 110 mmHg (around 13335 Pa) and the velocity inlet is time dependent following the sine wave 0.1*sin(4*PI*(t+0.0013)). when i run my simulation at 0.01 time step size my simulation runs smoothly. however, when i reduce the time step size to 0.001 i start getting unreasonably excessive displacements in the tube. the simulation fails after a couple of iterations in the first time step.

-

-

December 1, 2022 at 4:37 pm

Rahul

Ansys EmployeeHi,

Have you tried using monitors to identify the instability? You can monitor pressure/force convergence for FSI surfaces within each time step. Look at the graph of monitor point, poorly initialised case shows the sudden jump at the start of the run (improve initalization if this causes failure) and an unstable case starts with small oscillation that grows.

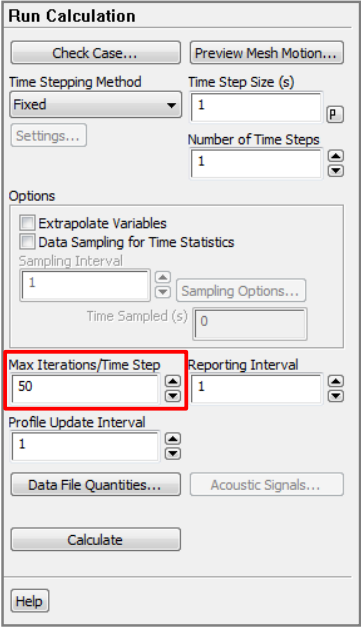

As it is unsable case, defults inputs of stabilization may not be sufficient. Look for appropriate inputs. If there are strong non-linearities within the coupled solution, then convergence within approximately 5 – 10 coupling iterations may not be possible. If this is suspected (and the previous recommendations are not sufficient to allow convergence), then increase maximum number of coupling iterations per step.

Try using more max. iterations/time step in Fluent.-

December 7, 2022 at 11:52 am

s.m.mousavi

SubscriberHi!

I could apply 2 of your suggestions to my numerical model:

1- I increased the maximum number of coupling iterations per step.

2- I increased the max. iterations/time step in Fluent.

However, my solution could not converge yet.

Can you please tell me how I can apply your first suggestion to my model?

"Have you tried using monitors to identify the instability? You can monitor pressure/force convergence for FSI surfaces within each time step."

I did monitor for example area-avereaged pressure in Fluent (not in my FSI simulations). But how I can do it while I am running the FSI simulations (the Fluent window is closed).

Thanks!

-

-

December 7, 2022 at 1:14 pm

Rahul

Ansys Employee-

December 7, 2022 at 5:05 pm

-

-

- The topic ‘Fluid structure interaction (FSI)’ is closed to new replies.

-

3762

-

1333

-

1168

-

1090

-

1014

© 2025 Copyright ANSYS, Inc. All rights reserved.