-

-

September 9, 2022 at 6:15 pm

javat33489

SubscriberHi guys.

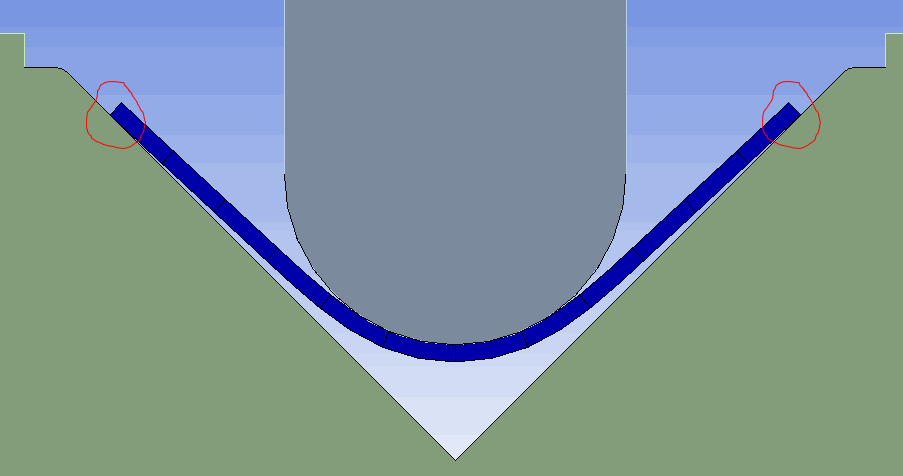

I have a problem with flex sheet. I am using bilinear kinematic hardening.

After the sheet is bent and the press comes back, the sheet flies 5000 mm.

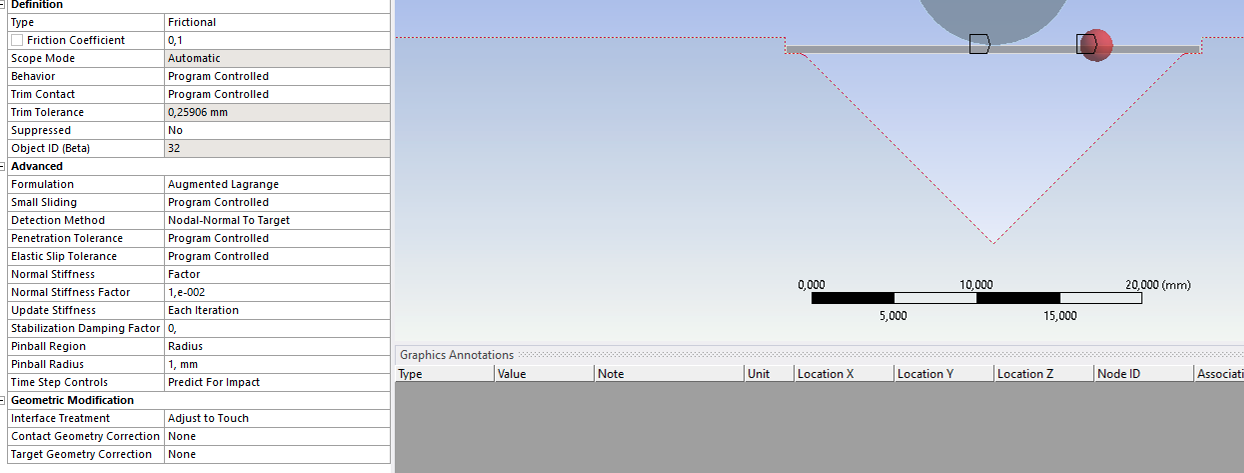

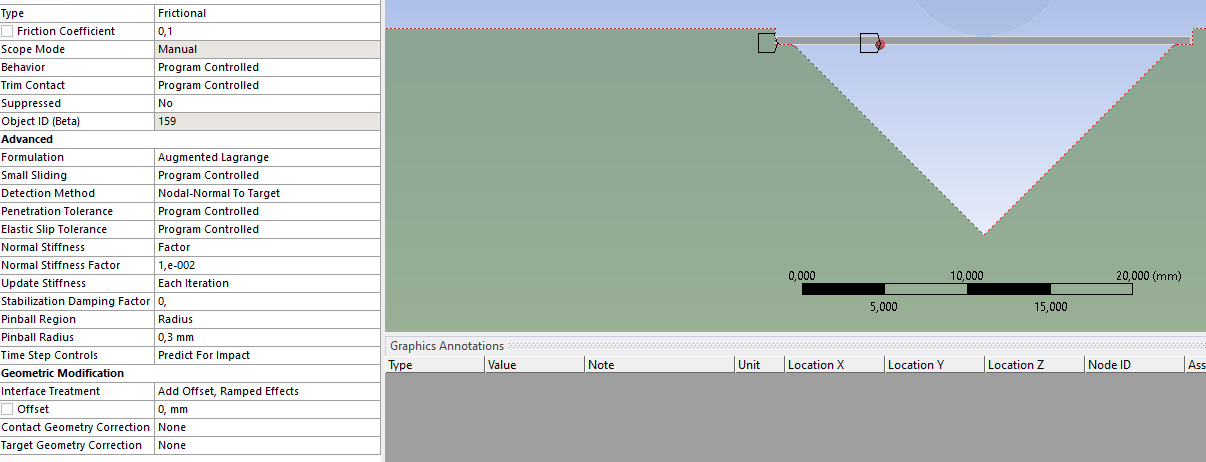

Contacts are all friction. I think the problem is in the contact between the press and the plate.

Help me please. I have attached animation and pictures.

-

September 9, 2022 at 7:11 pm

peteroznewman

SubscriberThis analysis might solve correctly by specifying a large number such as 100 for the Minimum Substeps in Analysis Settings, Step Controls.

-

September 9, 2022 at 8:11 pm

javat33489

SubscriberI have a minimum number of sub-stages of 2000 in one direction and 2000 in the other direction

-

-

September 9, 2022 at 8:24 pm

peteroznewman

SubscriberThe Minimum Substeps is not the reason for the failure since it is already a large number.

Putting a small radius on the bottom corner of the sheet body might help. That way there will be a small curve touching the line of the die instead of a single node touching the die as the punch retracts. This might prevent the failure you see.

-

September 9, 2022 at 8:31 pm

javat33489

SubscriberOkay, I'll try! Could there be a problem in the contacts that I showed in the pictures?

-

September 9, 2022 at 8:33 pm

-

-

September 9, 2022 at 8:56 pm

peteroznewman

Subscriber-

September 9, 2022 at 9:04 pm

javat33489

Subscriber

-

-

September 9, 2022 at 11:34 pm

peteroznewman

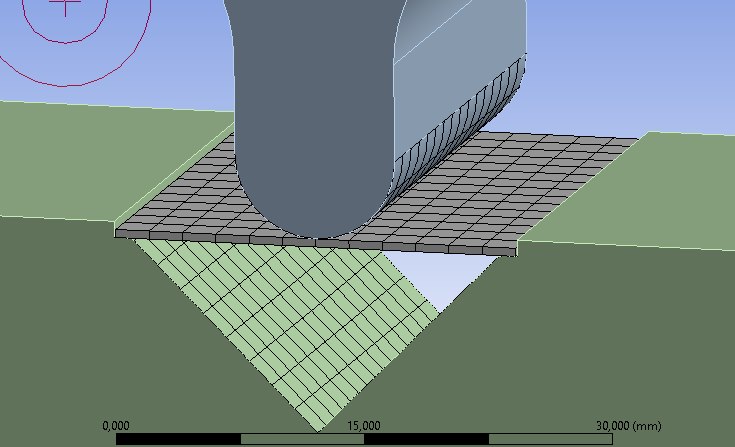

SubscriberA single solid element through the thickness of a sheet that will experience plasticity is unacceptable. Four quadratic elements or 8 linear elements through the thickness are a minimum for accurate computation of plastic strain.

Try remeshing with 8 linear elements and see if you have the same problem during the solution.

You haven't tried the rounded corner I suggested. That would require opening the solid body in the geometry editor and adding a blend to the edge of the solid body that makes contact with the die on the way up. That may not be needed after you increase the number of elements through the thickness.

-

September 10, 2022 at 7:27 am

javat33489

Subscriber>>You haven't tried the rounded corner I suggested.

I tried it, but I failed when I had one element per sheet thickness

thanks for the advice, I will increase the number of elements, if it does not help, I will make rounding on the edges of the sheets

-

September 10, 2022 at 12:07 pm

peteroznewman

SubscriberIt will be much faster to solve this problem as a 2D Plane Strain model.

-

September 12, 2022 at 4:10 pm

-

September 12, 2022 at 6:55 pm

peteroznewman

SubscriberTry turning on Standard Earth Gravity, that might help the part from rising up out of the die.

Also, turn off weak springs if they were turned on under Analysis Settings.

-

September 12, 2022 at 7:10 pm

javat33489

SubscriberWeak springs are off. I tried gravity. Nothing helps. Perhaps you need to solve the problem in dynamics and not in statics

-

-

September 12, 2022 at 10:24 pm

peteroznewman

SubscriberWhat is the goal of the analysis? If it was to determine the springback of the sheet after the die retracts, you have that. The rigid body motion after contact is lost can be subtracted off the deformation result.

You could add a small pressure load to the top surface of the sheet. Leave that pressure load on until the punch retracts, then ramp the pressure to zero in the next load step. Then gravity may be able to hold the part against the die.

You could try Transient Structural, but depending on the speed of the punch, the part may to want to launch itself toward the punch due to the springback. You will then have to let it fall back under a Gravity load until it settles in the die, but it might not be sitting level at the end time.

-

September 13, 2022 at 5:23 pm

javat33489

Subscriber>>You could add a small pressure load to the top surface of the sheet. Leave that pressure load on until the punch retracts, then ramp the pressure to zero in the next load step. Then gravity may be able to hold the part against the die.

not worked

>>You could try Transient Structural, but depending on the speed of the punch, the part may to want to launch itself toward the punch due to the springback. You will then have to let it fall back under a Gravity load until it settles in the die, but it might not be sitting level at the end time.

Transient Structural has the same problem

>>What is the goal of the analysis? If it was to determine the springback of the sheet after the die retracts, you have that. The rigid body motion after contact is lost can be subtracted off the deformation result.

i want to see the permanent deformation under different load also my goal is to get a residual two-formation of 2 mm, find out what kind of load is needed

-

-

September 13, 2022 at 8:24 pm

peteroznewman

SubscriberThe model you have shows the permanent deformation with some rigid body motion. You could export the deformation of the sheet at the end of the simulation, obtain the directional Y deformation of one "pilot" node, and subtract that value from all nodes. The "pilot" node will always have a Y deformation of 0. In that way you can superimpose the offset nodal data to look at differences in permanent deformation between loads.

-

September 13, 2022 at 8:26 pm

peteroznewman

SubscriberI expect if you keep increasing the pressure load, eventually, the part will stay in the die as the punch retracts.

I also expect if you simulate a Transient Structural for a long enough time, gravity (or a large acceleration load) will eventually pull the part down to rest in the die.

-

September 14, 2022 at 2:28 am

javat33489

SubscriberWhen I apply force or pressure to the sheet to press it, the calculation stops with an error while the punch tries to separate from the sheet.

-

-

September 14, 2022 at 3:15 pm

peteroznewman

SubscriberI would be curious to see the model if you would be willing to share the .wbpz archive file on a file sharing site such as Google Drive, Dropbox or Jumpshare, which is what I use. If you use Google Drive, make sure to mark the file so it will download for anyone who has the link.

-

September 15, 2022 at 6:07 pm

-

-

September 16, 2022 at 2:55 am

peteroznewman

SubscriberThanks! I will take a look at this on the weekend.

-

September 18, 2022 at 1:06 pm

peteroznewman

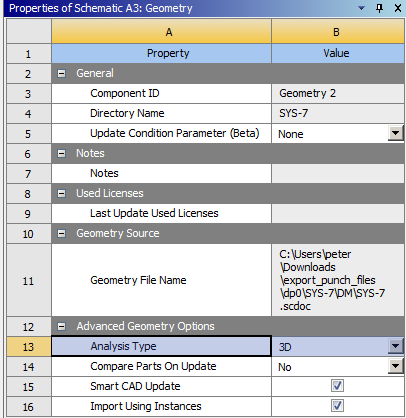

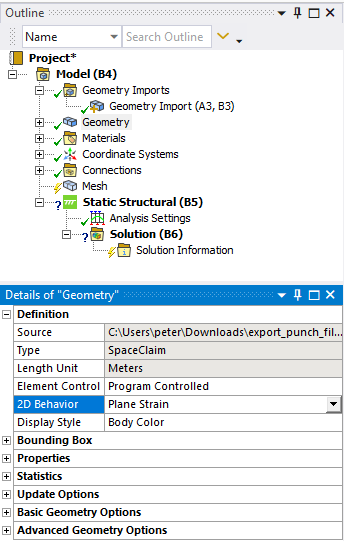

SubscriberThe archive you shared is not a 2D plane strain model. It is a 3D model. See where it says Analysis Type 3D. That would say 2D if you had a 2D model. Just having sheet bodies in the XY plane is not sufficient to get to a 2D model.

Once you have built the model in 3D, that analysis can’t be switched to 2D later. You have to start over with a new analysis and set it to 2D before you open the Model cell.

If I start a new analysis, I can link to the Geometry cell, but in the new analysis, I set it to 2D. Then when I open the Model cell, I can specify what type of 2D analysis I want. In this case it is Plane Strain.

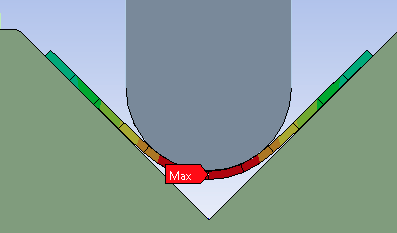

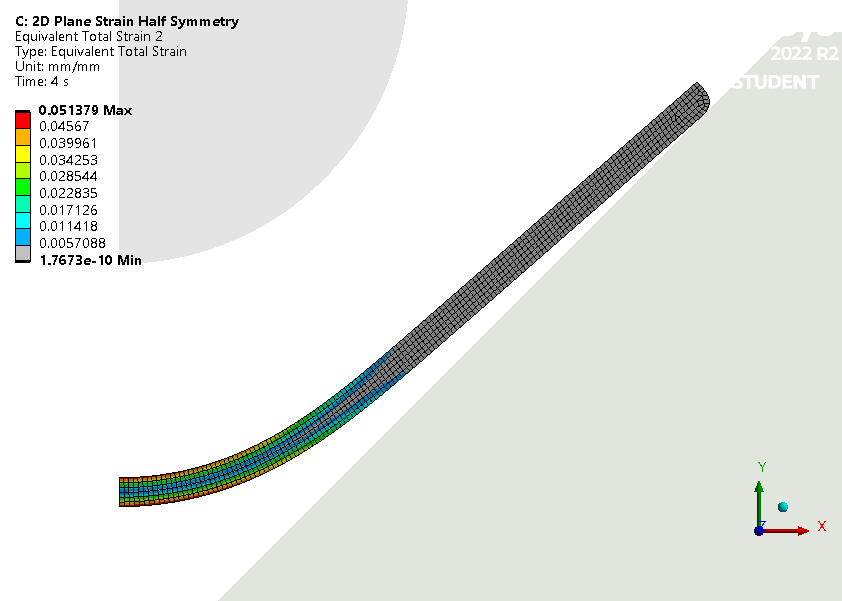

The solution is easier and faster if you take advantage of half symmetry. Here is the result:

It is difficult for the contact algorithm to have the punch separate from the sheet. I used Contact Step control to soften the contact after step 1, then move the punch up to the point just before contact separation, then I made the contact “Dead” in the next step and finally moved the punch up some more.

Here is the ANSYS 2022 R2 archive: https://jmp.sh/kboP9lt

-

September 18, 2022 at 5:14 pm

javat33489

SubscriberThanks a lot!!! I will look into my mistakes!

-

-

September 18, 2022 at 5:19 pm

-

September 18, 2022 at 5:49 pm

peteroznewman

SubscriberSorry, I don't know LS-Dyna at all.

-

- The topic ‘Problem with flex sheet’ is closed to new replies.

-

5139

-

1831

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.