-

-

May 9, 2022 at 5:02 pm

saad1996

SubscriberHello,

I am running a structural analysis in which a beam is cooled down to a certain temperature and then reheated back to the original temperature. The temperature vs thermal strain relation is different for the heating and cooling stages. is there a way I can define these different material properties for the different steps

May 10, 2022 at 10:52 amVinayak Vipradas

Ansys Employee

Please refer to the following post:

Applying different materials on different steps ! ÔÇö Ansys Learning Forum

Regards Vinayak

Ansys Help

Ansys Learning Forum (Rules & Guidelines)

May 10, 2022 at 8:52 pmsaad1996

SubscriberThanks For Your Response I tried applying the change in material properties as an apdl command as shown in the sample example and while the model runs, the results obtained for the second step are completely off. I have attached the apdl code I used below:

MP,EX,2,60000

MP,NUXY,2,0.2

!EMODIF,ALL,MATID,2

MPCHG,2,ALL

Note that in this attempt, I only changed the elastic modulus from 30000 to 60000 for the purpose of trying out the command. Do you have any idea where I may have gone wrong?

I highly appreciate your help

May 11, 2022 at 12:57 pmMay 11, 2022 at 3:08 pmsaad1996

Subscriberhello Yes, I changed the step number as shown

May 11, 2022 at 3:26 pmgreg2835

SubscriberAre you trying to change modulus of specific elements? Or is the beam a single element? Did you deactivate thermal strain?

May 11, 2022 at 3:51 pmsaad1996

SubscriberThe entire beam is a single element. I tried running the model with thermal strain on and off but both give garbage answers for the second step. Please let me know what other information might be helpful for solving this problem as I have been trying to figure it out for a while now.

Thank you

May 11, 2022 at 3:55 pmgreg2835

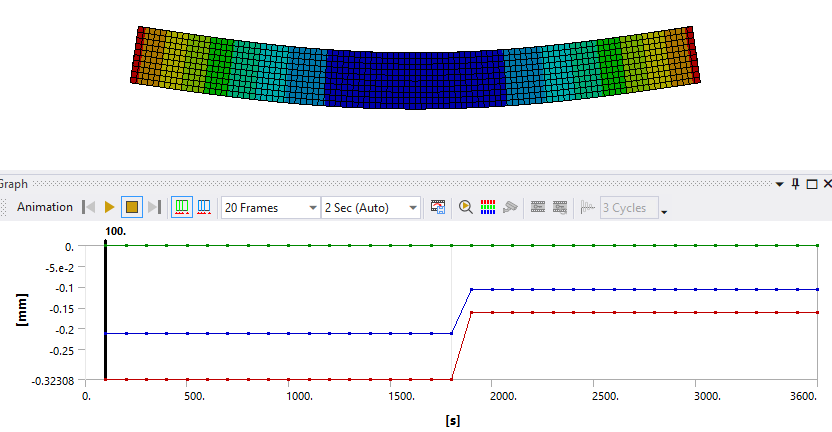

SubscriberNot too sure. I ran it on a single element and got expected results (see below). Like you I just doubled the modulus and got half the deflection. Does your material have a temp vs modulus table in Engineering Data? If so I would remove that, not really sure what else it would be without seeing your setup

May 11, 2022 at 4:28 pmsaad1996

SubscriberI am sorry, i misunderstood your initial question, the beam is composed of several elements but I want to change the material for all elements. I defined the material and element type for the initial step as shown below. I have also attached the obtained results after the two time steps.

! Defining the element type

ET,MATID,CPT215

! Elastic constants

MP,EX,1,30000

MP,NUXY,1,0.2

May 11, 2022 at 5:10 pmgreg2835

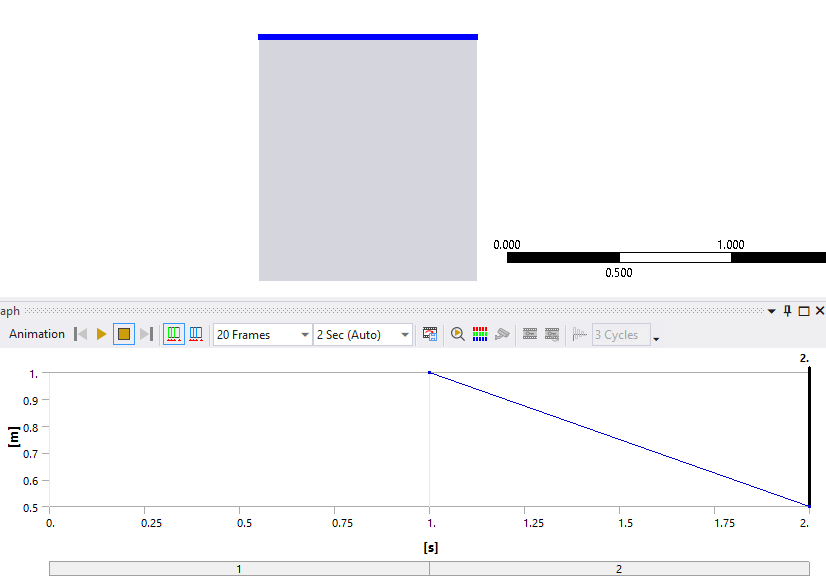

SubscriberHmm I'm not sure what to tell you. I made a quick similar analysis and it works fine. Can you show how your loads and BCs are setup?

May 11, 2022 at 5:40 pmsaad1996

SubscriberThe only load I applied for now is the standard earth gravity and the boundary conditions are defined as nodal displacements at each end. The center node at one face has a nodal displacement of zero in all three directions while the central node on the other side has a nodal displacement of zero in the x and y directions and is free to move in the z direction (along the axis of the member).

May 11, 2022 at 5:52 pmgreg2835

SubscriberCan you export the project and attach it? I might be able to take a quick look and figure it out (I have the day off anyway)

May 11, 2022 at 6:13 pmsaad1996

SubscriberI have attached the file. Thanks again for your help

May 11, 2022 at 7:10 pmgreg2835

SubscriberIn your Command, change the 2's to 1's. You only have one MatID, which is 1. You also need to adjust your time steps. I was seeing some twisting on the first step which shouldn't be present.

May 11, 2022 at 7:11 pmMay 11, 2022 at 7:23 pmsaad1996

SubscriberThanks Greg. It works fine now. I will now try to adjust this approach to modify the thermal properties that I need.

Viewing 15 reply threads- The topic ‘How to change material properties or material assignment in between steps’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

4597

-

1495

-

1386

-

1209

-

1021

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

Ansys Assistant

Welcome to Ansys Assistant!

An AI-based virtual assistant for active Ansys Academic Customers. Please login using your university issued email address.

Hey there, you are quite inquisitive! You have hit your hourly question limit. Please retry after '10' minutes. For questions, please reach out to ansyslearn@ansys.com.

RETRY