TAGGED: johnson-cook

-

-

April 12, 2022 at 1:27 pm

javat33489

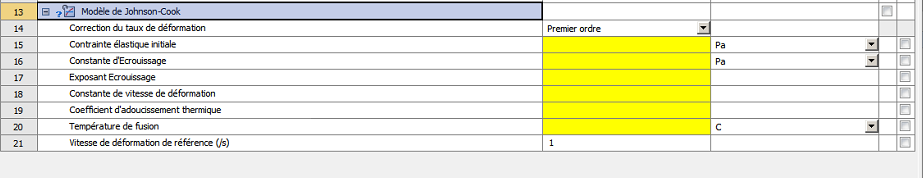

SubscriberHello. Friends I have a problem. I have a strain/stress graph. Now I need to find the deformation parameters for Johnson-Cook (A, B, C, n, m). There are no tutorials on how to do this. There are a few videos on youtube but it's not clear. Could you tell me how to do it consistently? The points. Do you have an excel spreadsheet?

April 13, 2022 at 4:30 pmAshish Khemka

Forum Moderator

Please see if the following link helps:

Johnson-Cook Failure for Copper ÔÇö Ansys Learning Forum

Regards Ashish Khemka

April 13, 2022 at 5:58 pmjavat33489

SubscriberThanks for the answer, but it doesn't work for me. I tested steel on the stand. I have a graph, I made a strenght and stress curve from this graph. Now, using these data, I need to find data for the Johnson-Cook deformation. Like here: https://www.youtube.com/watch?v=vRTgY1HikUQ&pp=ugMICgJydRABGAE%3D But this video is not clear. I would like a more detailed description of how to do this. Or maybe there is a ready-made Excel table where you could drive in the chart parameters and get Johnson-cook data

April 14, 2022 at 2:24 pmApril 15, 2022 at 5:53 pmjavat33489

SubscriberFriends, I do not understand the parameter T. This is the temperature, but how to find it correctly?

(T-T0)/(Tp-T0)

Friends, I do not understand the parameter T. This is the temperature, but how to find it correctly? (T-T0)/(Tp-T0) what is T?

April 15, 2022 at 5:53 pmjavat33489

SubscriberSeveral temperatures are needed, but what are these temperatures? Where can I get them?

April 18, 2022 at 8:44 pmChris Quan

Ansys EmployeeThe reference paper of Johnson-Cook Strength & Failure models can be found from: Engng. Frac. Mech. Vol 21. No. 1. pp 31-48. 1985Johnson + Cook. You can get this paper to find how they conduct the experiments to obtain the material data for the Johnson-Cook models.

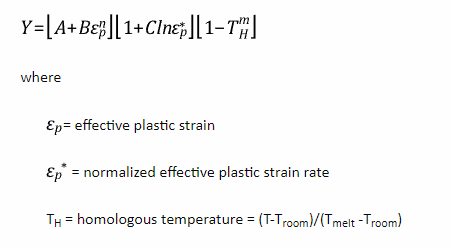

In terms of temperature, T is the current temperature calculated from the local plastic work done, T0 is the initial reference temperature (stress-free), and Tp is the temperature for melting. When the deformed material has done a lot of plastic work, it will increase the temperature in the heavily deformed material. The increase of the temperature will further reduce the yield stress of the material. This is also called as "thermal softening".

April 19, 2022 at 7:11 pmjavat33489

SubscriberOkay, I'm confused. But I still have a question. If I tested the sample only once at room temperature, then T = 273K, T0 = 273K, then (T-T0)/(Tm-T0) = 0 because 273-273 = 0. What to do with T if the tests were carried out once and at room temperature? T=T0? What T to use?

The second question, when plotting to find the parameter B, I get too small B:

according to the schedule it is 3.3, EXP3.3 is very little?

watch the video how to find parameter B i did the same

https://www.youtube.com/watch?v=vRTgY1HikUQ

April 20, 2022 at 6:29 pmChris Quan

Ansys EmployeeYes, it is true that T_H is equal to zero due to T = T_0 at the beginning of the simulation.

Thus, the third term of the Johnson-Cook model is equal to 1, which means no thermal softening at this temperature. See attached picture below.

Thermal softening starts when the temperature in an element is elevated and has exceeded the initial temperature.

April 20, 2022 at 6:47 pmjavat33489

Subscribernow everything is clear thanks!

it remains to understand why I have such a small coefficient B

February 15, 2023 at 5:47 pmJune 22, 2023 at 4:01 pmjaideep18

SubscriberI cannot find the value for static damping in the Damping control under the Analysis setting for Ti6Al4V grade 23 material. Could you please help me with that. Thank you

Viewing 11 reply threads- The topic ‘Parameters for Johnson-Cook’ is closed to new replies.

Ansys Innovation SpaceTrending discussionsTop Contributors-

3767

-

1333

-

1173

-

1090

-

1014

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-