TAGGED: brittle-failure, structural-mechanics

-

-

February 10, 2022 at 5:01 am

matus

SubscriberHi

I am working on a transient thermal-mechanical simulation.

Project description

A simple cylinder is undergoing cooling from the surrounding. After the cooling, the temperature of the cylinder drops below the glass transition temperature. Then a force is applied to the cylinder. I wanted to find the force required to break the cylinder. How can solve this? ( I have completed the thermal simulation. I wanted to perform the mechanical)

The idea of this project is simply to compare the force required to crush the cylinder with and without cooling.

Is this problem falls under non-linear analysis?

February 11, 2022 at 1:36 ampeteroznewman

SubscriberYes, it is a non-linear analysis.

The mechanical model that predicts the force to break the cylinder requires, for the simplest approach, the information on ultimate tensile strength of the material.

Usually, experiments characterize the strength of the material at many temperature settings using a standard test coupon.

February 16, 2022 at 4:56 ammatus

SubscriberThanks for your reply.

Can you please explain more about the approach I need to take to find the force required to break the material under compression? I am a bit confused about the approach I need to take.

what is the most important property considered when the ductile-brittle transition occur?

February 16, 2022 at 12:47 pmpeteroznewman

SubscriberWhat is the material that you want to simulate?

What material properties do you already have on this material?

February 17, 2022 at 7:08 ammatus

SubscriberThanks for your reply.

I would like to use SS 304. I have the following temperature-dependent properties

YoungÔÇÖs modulus, PoissonÔÇÖs ratio, Compressive yield strength, Tensile yield strength, Compressive ultimate strength, Compressive ultimate strength.

I would like to find the force required to fracture the cylinder under tensile and brittle conditions.

Thank you

February 17, 2022 at 12:51 pmpeteroznewman

SubscriberIn the original post, you mentioned the force to crush the cylinder, while in the last post you mentioned tensile conditions. Crushing is a compressive condition so I am confused.

Please inset an image into your reply showing the cylinder, the support and the direction of applied force.

February 18, 2022 at 4:57 ammatus

SubscriberSorry for the confusion.

I am looking for the force required to crush the cylinder under brittle and ductile conditions.

so, this problem comes under compressive conditions.

I have also attached a diagram of the cylinder.

February 19, 2022 at 9:39 pmpeteroznewman

SubscriberI expect a plate will push on the sample with a force.

You wouldn't want to apply a force to the top face of the sample directly because the edges are not as stiff as the center and so will deflect more than the center. This would not happen if there was a plate pushing on the top of the sample.

A model with a Force is simple. A model with a plate is more complicated. What do you want to do?

February 21, 2022 at 3:38 ammatus

SubscriberThanks for your reply.

I am looking for a model with force applying from the top.

February 21, 2022 at 6:22 pmpeteroznewman

SubscriberOkay, that is very simple to create. Open Mechanical, drag out Static Structural and drop it on the Project page. Open Engineering Data and create all your Temperature Dependent material properties.

Double click on the Geometry cell and SpaceClaim will open. Draw a circle of the desired diameter, then click the Pull tool and drag it up to the desired length. Close SpaceClaim. Double click on Model and Mechanical will open. Assign the material to the solid. Apply a Fixed support to one end of the cylinder. Apply a Force to the other end of the cylinder.

Add some Stress results for Von Mises and Max Principal Stresses. This first model is for the default Environmental temperature of 22 C. Compare the ratio of the maximum stress with the Yield Strength and the Ultimate Tensile Strength at this temperature. Multiply each ratio with the applied Force to calculate the Force at Failure for each type of failure at this temperature. There is a Safety Factor tool that does this automatically for you. Change the Environmental Temperature to a higher or lower value and solve the model to get new stress results and Safety Factor for this new temperature.

The above is for a uniform temperature of the whole cylinder.

If you have a Transient Thermal model, you can link the Solution cell of that to the Setup cell of the Static Structural model and check the stress at different times in the Thermal solution.

February 22, 2022 at 9:29 ammatus

SubscriberThanks for your reply. I have really appreciated your detailed response.

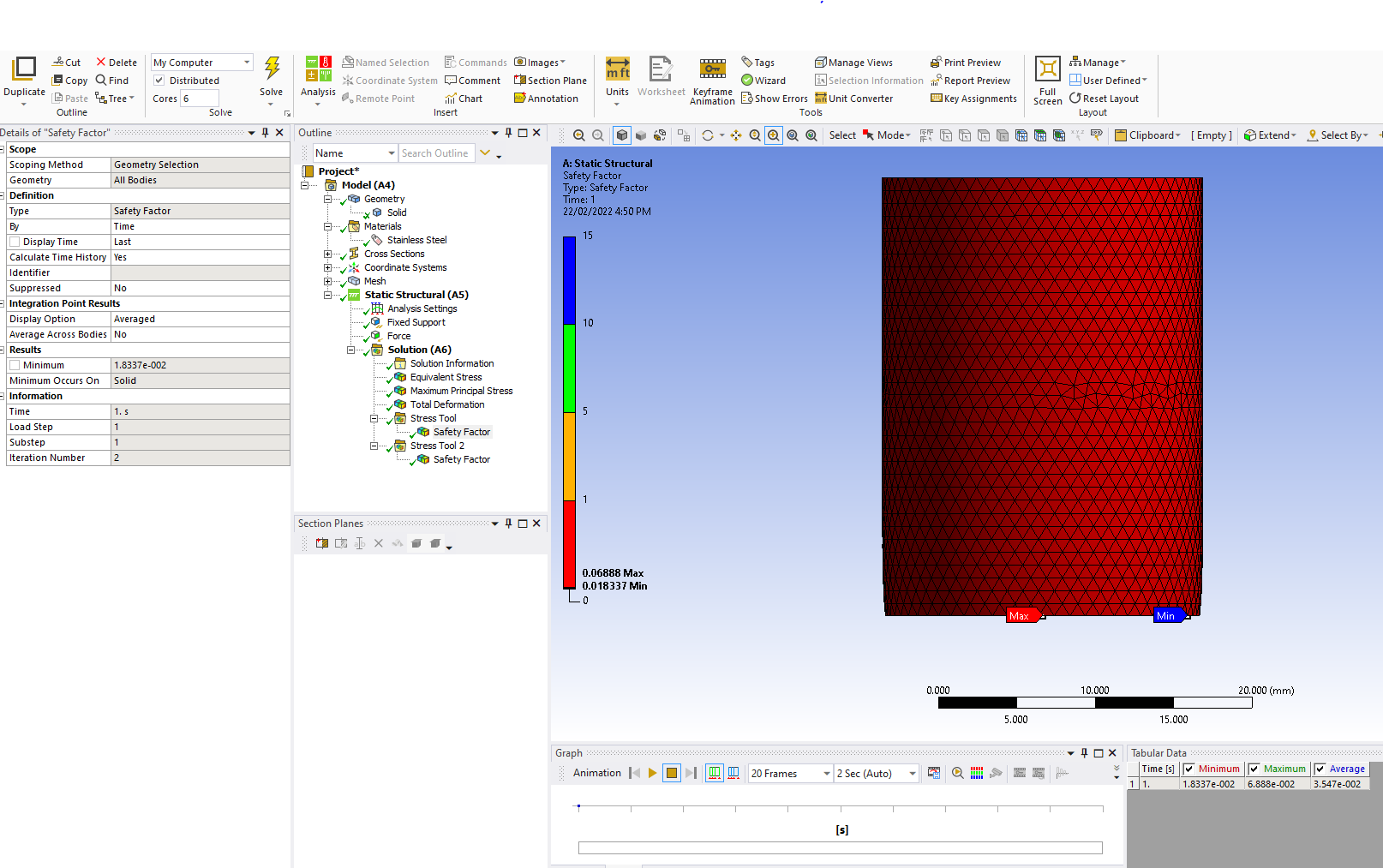

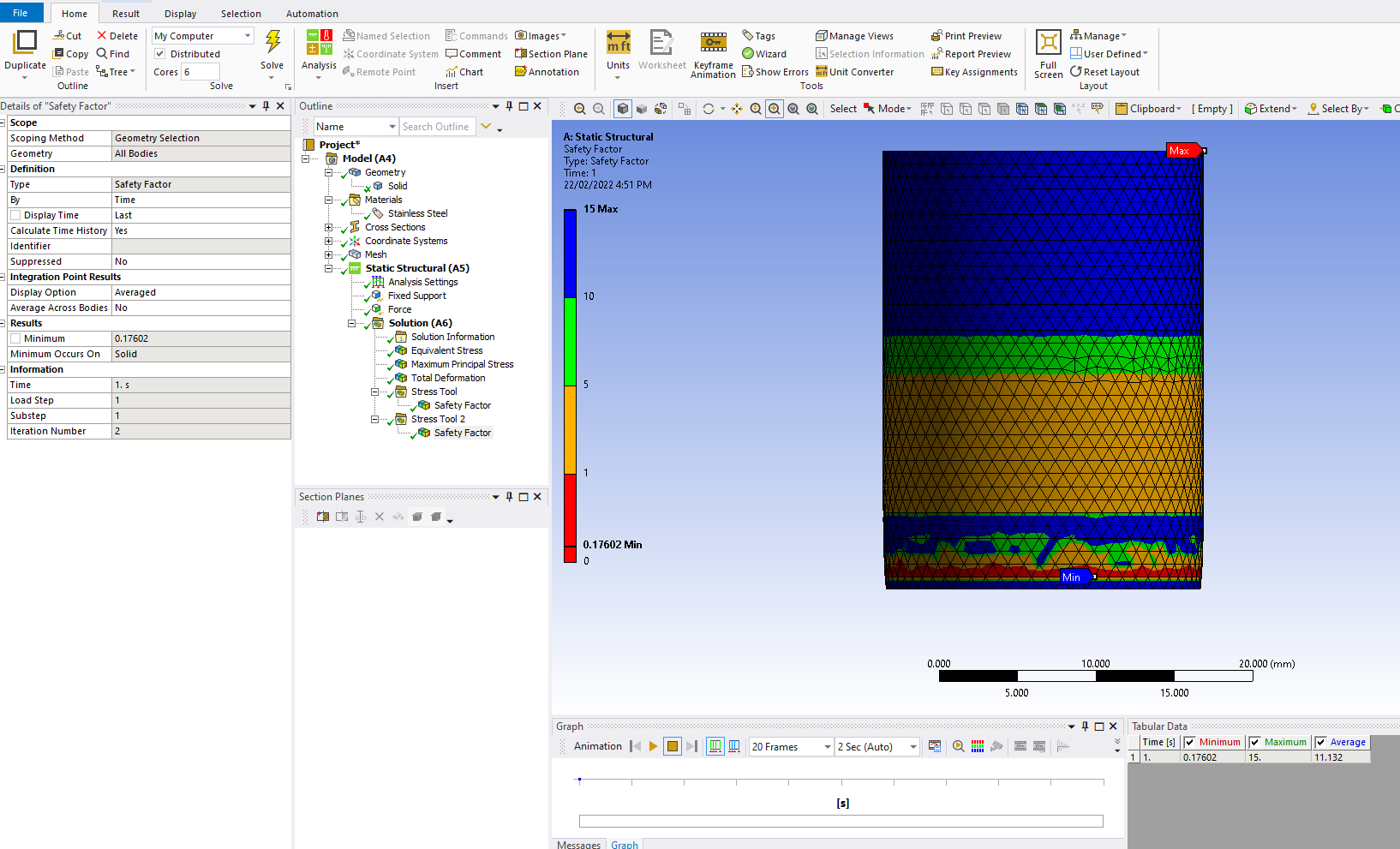

As per your suggestion, I have completed the simulation. But I still have confusion with the final result. At 22 C, When a force of 2E6 N is applied, the simulation result shows that the applied stress reached above the yield stress ( FOS falls below 1). Similarly, the FOS with ultimate stress falls below 1 in some cylinder regions. (attached screenshots)

At 22 C, stainless steel's yield and ultimate stress value are 2.07E8 and 5.86E8, respectively.

Next, I would like to do the same analysis at low temperatures (-196 C). I have noticed that the value of yield and ultimate stress increases as the temperature decreases.

At -196 C, yield and ultimate stress values are 2.34E8 and 1.07E9.

If so, should I need to apply more force in the -196 C condition than in-room temperature to fracture the cylinder?

My initial thought was the lesser force required below the glass transition temperature(brittle stage) to fracture material than in-room temperature( ductile stage).

Do I need to consider any other properties (e.g., impact strength) to complete the simulation?

February 22, 2022 at 12:56 pmpeteroznewman

SubscriberSince this is a compressive test, I should have said to insert a Minimum Principal Stress result and compare the minimum value (which will be negative) with the Ultimate Compressive Strength, which should have a minus sign on it also.

If the materials have larger magnitude (more negative) values of Compressive Strength in the cold than at room temperature, then a higher force would be needed to create a value of Min Prin Stress that equals that strength. Do you have temperature dependent properties for Young's Modulus? That will change how much stress is created for the same amount of force if it changes with temperature.

The most inaccurate part of this simulation is the Fixed Support and the Force on the top. Real samples will be placed on plates so that the face touching the plate can expand as the stress increases due to Poisson's Ratio. A more accurate model would use frictional contact to press on the sample. One way to reduce the modelling effort is to use a Symmetry Plane and slice the cylinder to half the height. That way, you only need to model one plate. Another simplification is to use two more planes and slice the body into 1/4 of a cylinder.

March 2, 2022 at 3:59 ammatus

SubscriberThanks for your reply.

March 18, 2022 at 7:25 pmMedri17

SubscriberHi matus , i have my final project on a quiet similar problem , but im new to this , could i have ur email or discord so i can task u a few questions if u dont mind ?

Viewing 13 reply threads- The topic ‘How to perform mechanical simulation of a brittle cylinder?’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

5279

-

1885

-

1403

-

1262

-

1021

Top Rated Tags© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-