TAGGED: ansys-fluent, mesh-generation, meshing, static-structural, workbench

-

-

February 5, 2022 at 1:11 am

Mountain1002

SubscriberHello everyone,

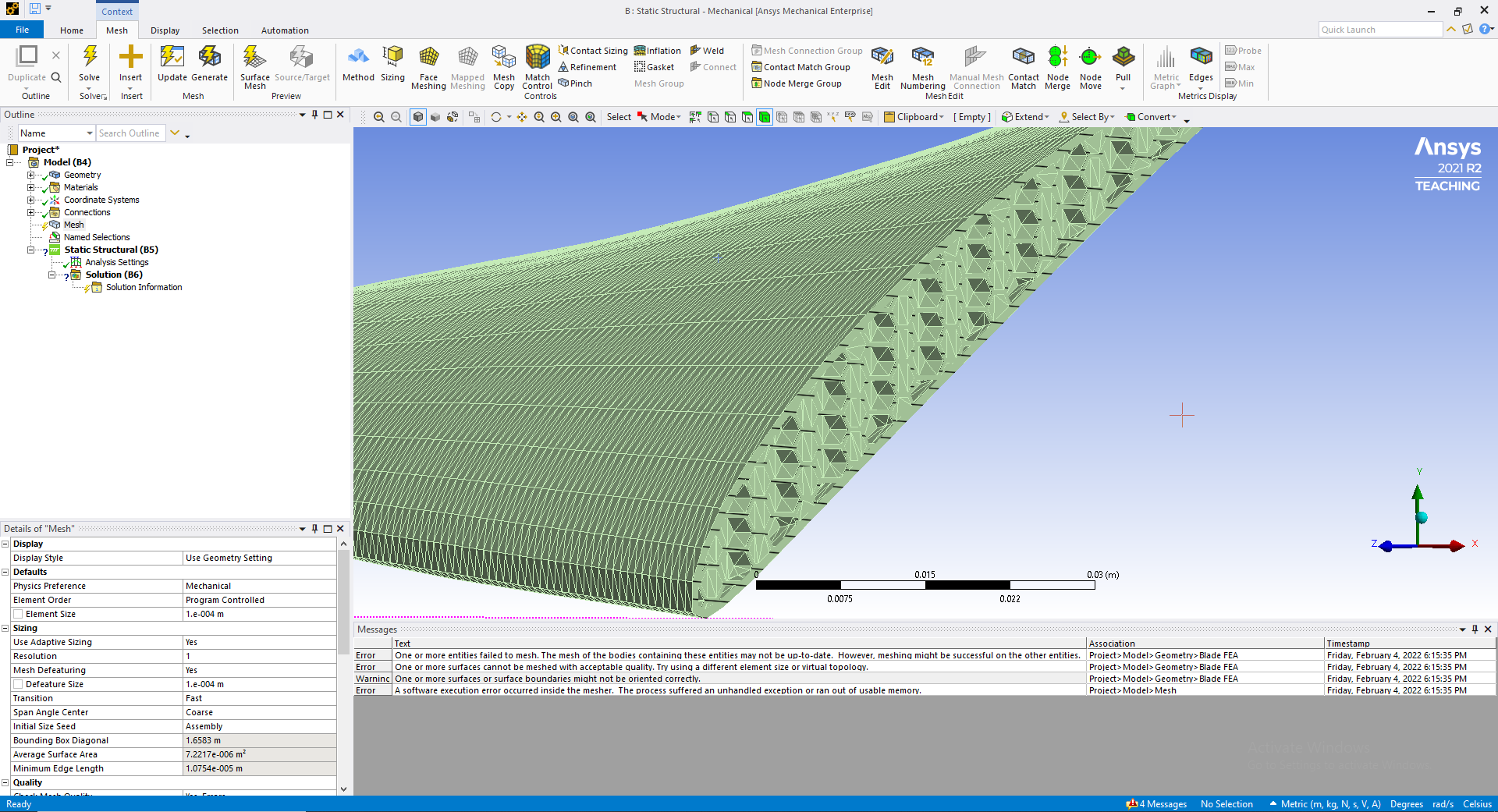

I am trying to obtain a deflection contour/figure of the turbine blades in ANSYS Static Structural. However, when I tried to mesh those blades, ANSYS gave me 3 errors with 1 warning. Those are:

1) Error: One or more entities failed to mesh. The mesh of the bodies containing these entities may not be up-to-date. However, meshing might be successful on the other entities.

2) Error: One or more surfaces cannot be meshed with acceptable quality. Try using a different element size or virtual topology.

3) Error: A software execution error occurred inside the mesher. The process suffered an unhandled exception or ran out of usable memory.

4) Warning: One or more surfaces or surface boundaries might not be oriented correctly.

February 5, 2022 at 4:19 ampeteroznewman

SubscriberSpaceClaim created geometry for a 3D printer to make the wing. This geometry is too complex to mesh. Structural analysis nearly always needs a simplified representation of the true manufactured geometry. In this case, you want to represent the full density 0.8 mm skin as one material property, and the 20% dense core as a second material property.

You can most easily represent the structural model by taking the wing geometry and reduce it by the 0.8 mm skin thickness so you have a solid model of the core. By this I mean the solid has no holes, it is solid with a low density material assigned to it. Mesh that with quadratic tet elements using the core material property. Then use the Surface Coating capability of Mechanical to apply quadratic tri shell elements, with a 0.8 mm thickness assignment, to the surface of the core and use the full density material for those shell elements.

February 5, 2022 at 5:05 pmMountain1002

SubscriberHello @Peteroznewman,

Thank you for the reply, and I'll follow that procedure.

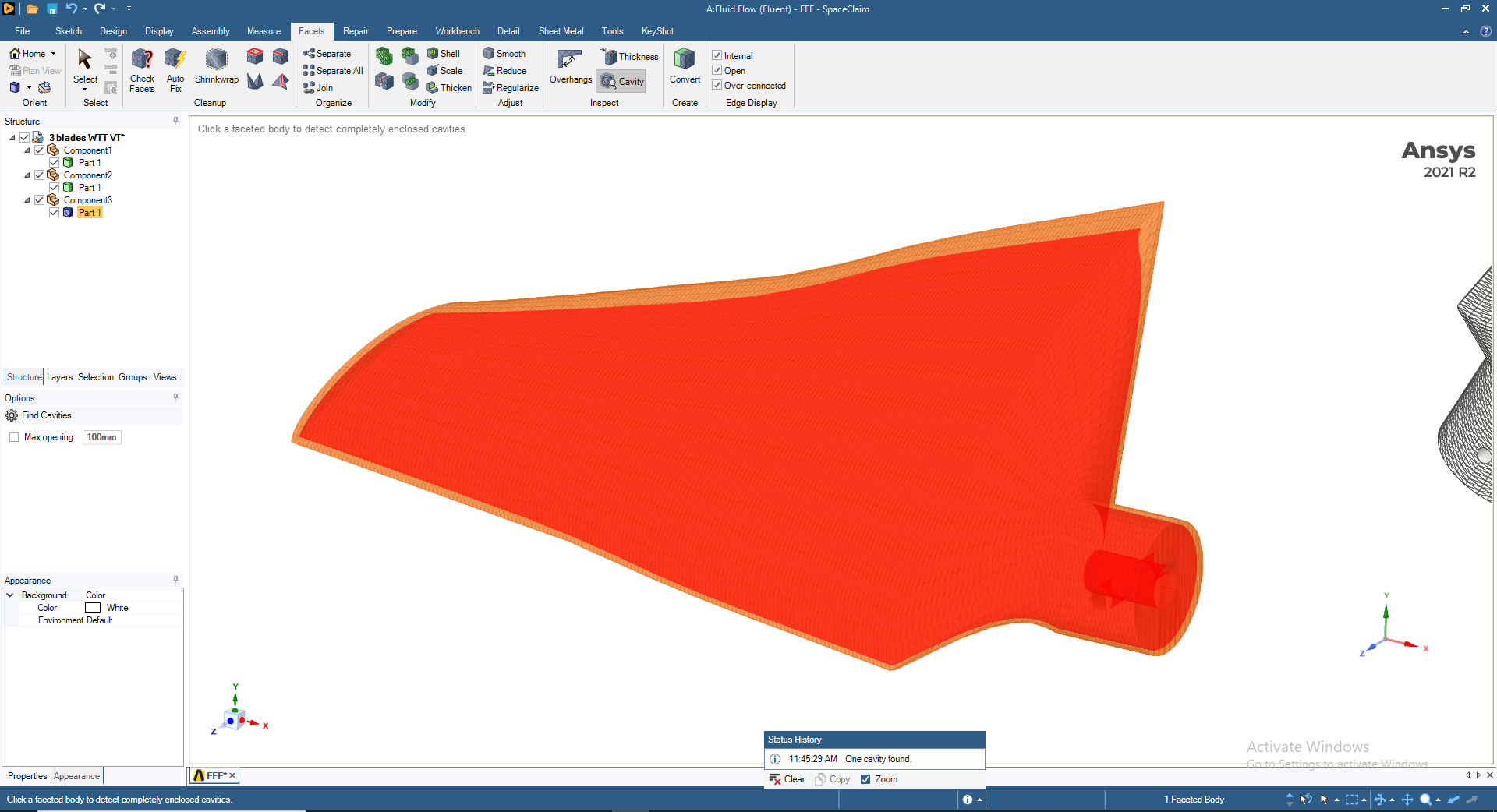

I tried to fill up the empty space in ANSYS SpaceClaim using methods like...

1) Cavity - filling the enclosure with solid

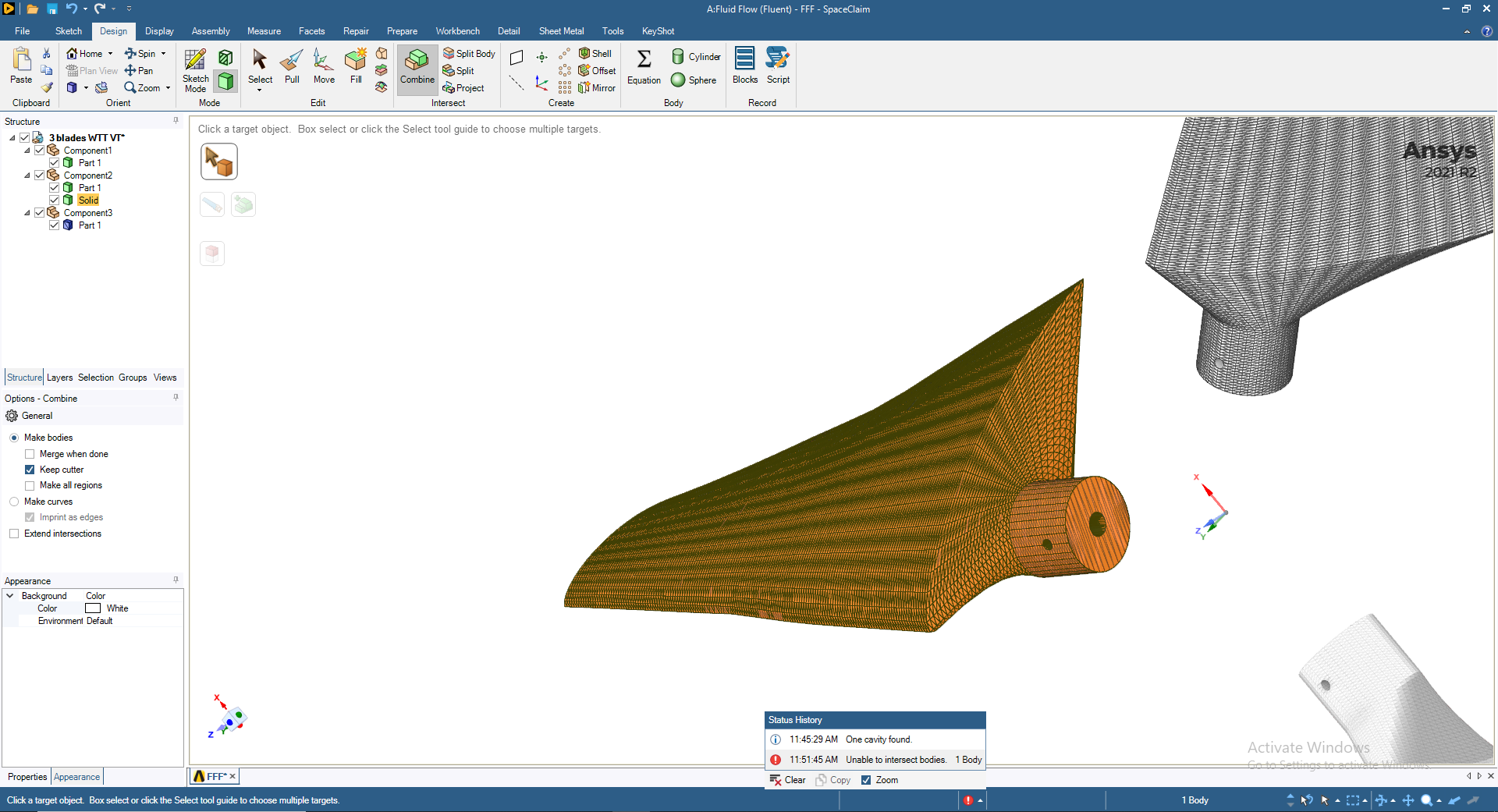

2) Combination - subtracting the shell part from the original part

2) Combination - subtracting the shell part from the original part

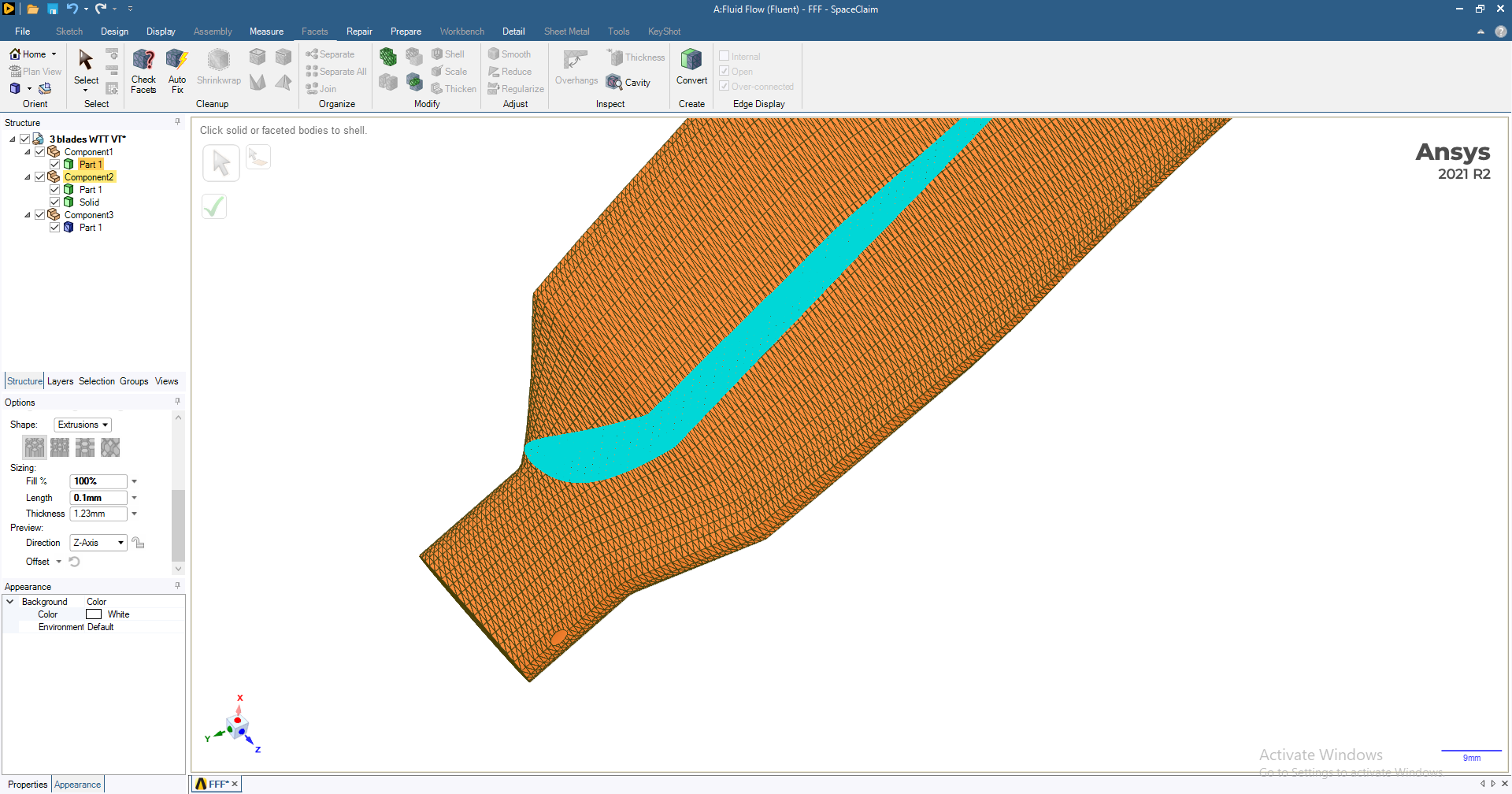

3) Infill - filling the enclosure with solid based on fill percentage

3) Infill - filling the enclosure with solid based on fill percentage

With the Cavity method, it found one cavity, but it didn't do anything. As for Combination method, an error appeared saying "Unable to intersect bodies". Lastly, the Infill method just combined the shell part with the infill part. Sorry... I new to ANSYS.

With the Cavity method, it found one cavity, but it didn't do anything. As for Combination method, an error appeared saying "Unable to intersect bodies". Lastly, the Infill method just combined the shell part with the infill part. Sorry... I new to ANSYS.

Do you know how to fill with a solid part that's in an enclosed solid part?

February 5, 2022 at 6:49 pmpeteroznewman

SubscriberDo not try to fill the part that was prepared for 3D printing. That file is not useful to you.

Start with the original solid body of the wing, before any 3D printing features were created.

Offset the surfaces by 0.8 mm.

Viewing 3 reply threads- The topic ‘Having trouble with meshing turbine blades (with internal structure)’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

4613

-

1530

-

1386

-

1209

-

1021

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-