TAGGED: boiling-point, dpm, evaporation, phase-change

-

-

January 31, 2022 at 7:27 am

Beb99

SubscriberHey all,

I'm trying to simulate evaporation in a discrete particle and ran into something unusual.

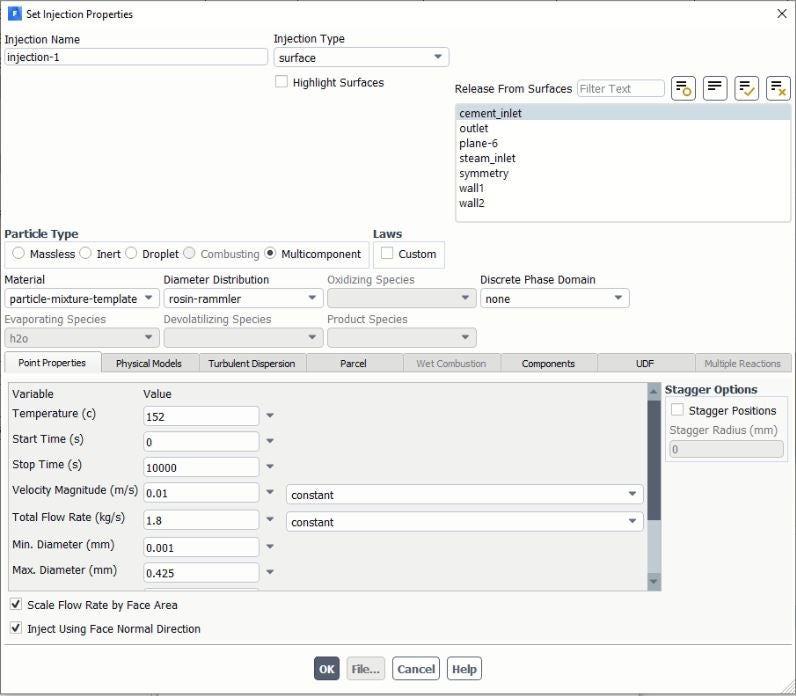

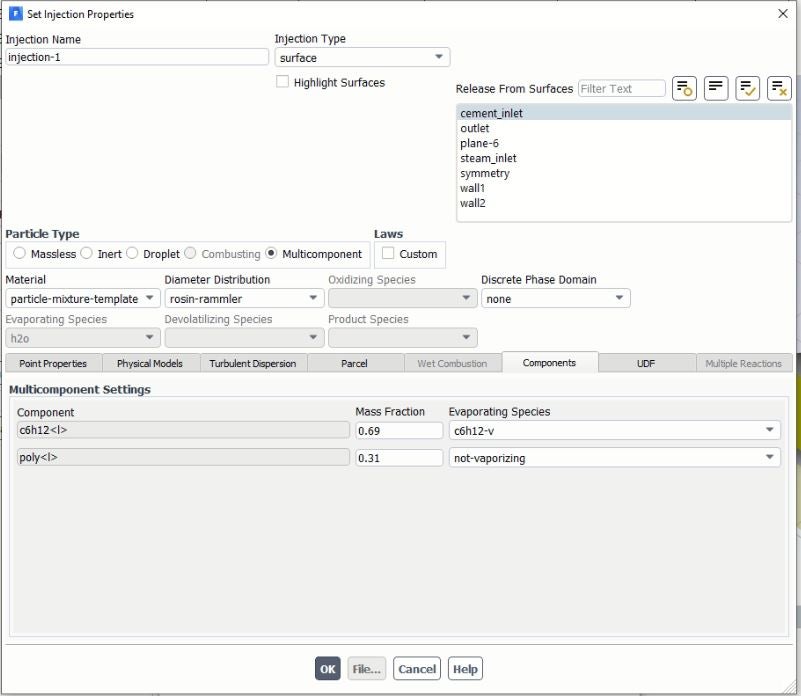

My injection inlet is a discrete phase mixture of a 30% polymer(non-evaporating) and 70% volatile component(liquid, can evaporate) at a temperature of 180C.

The boiling point of the volatile is 85C (at 1 atm) and I've added the volatile in gaseous form too in the material tab and selected it in the evaporating species tab. I'm expecting the volatile liquid to instantaneously evaporate but it is not happening at the boiling point of 85C (Please, note that the temperature of the inlet particle is much higher than its boiling point and the pressure of the domain is not very far from 1atm range).

But, when I raise the boing point to let's say 120C (previously 85C) and keep everything else the same, I'm seeing significant evaporation and when I raise it to even further let's say 300C, every particle in the volatile liquid is evaporated.

Can anyone help me to understand why this is happening and why it is not evaporating in the original condition (BP of 85C) in the first place?

The domain is a cylindrical pipe with dry air at the inlet surface, the discrete particles are injected circumferentially at some distance from the air inlet. The opposite face to the air inlet is the outlet.

Thank you,

Beb99

January 31, 2022 at 1:48 pmRob

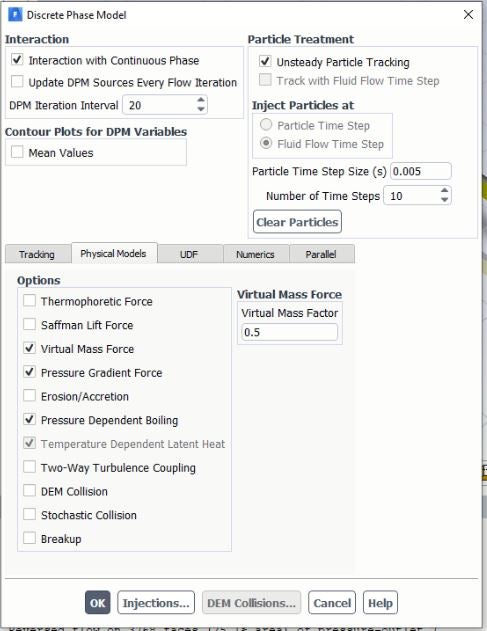

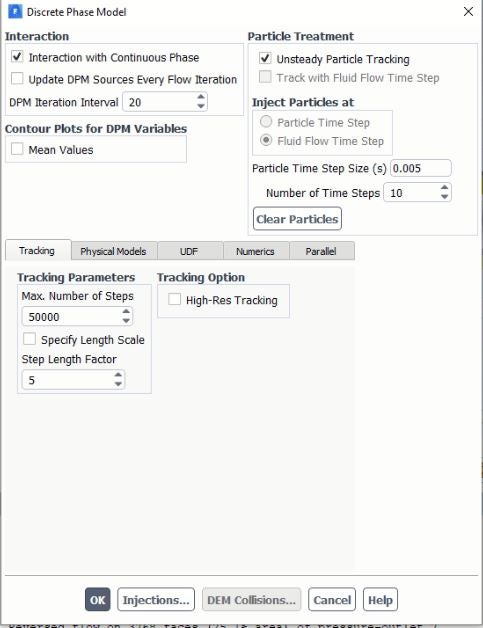

Forum ModeratorI assume you set the volume fraction in the injection? Please post a screen shot of the injection settings.

February 1, 2022 at 11:36 amFebruary 1, 2022 at 1:43 pmAmine Ben Hadj Ali

Ansys EmployeeMulticomponent will use cell pressure and vapor pressure information to model vaporization and boiling.

February 2, 2022 at 8:57 amBeb99

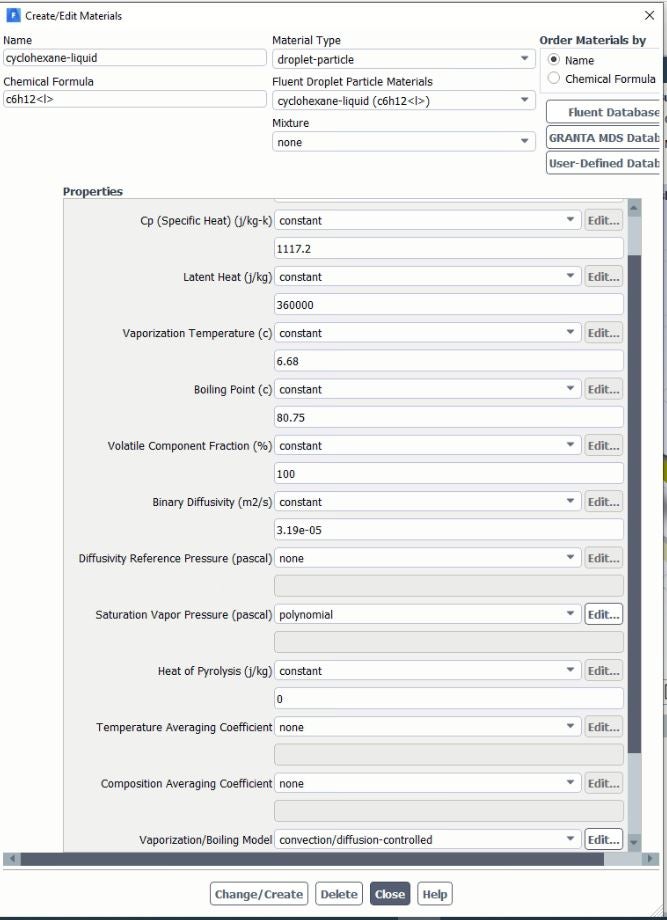

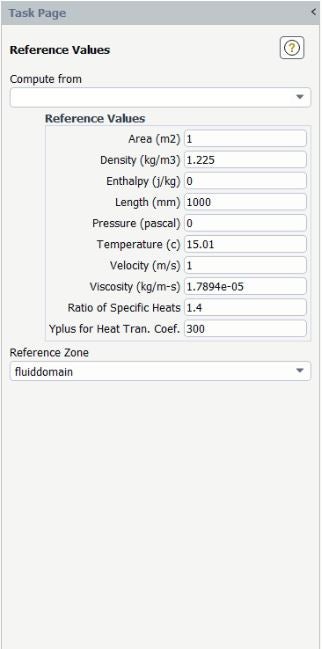

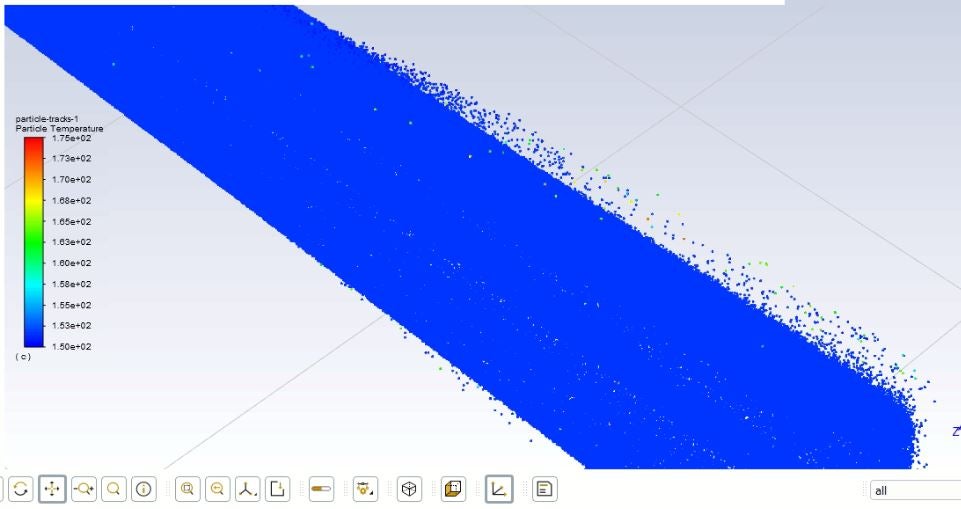

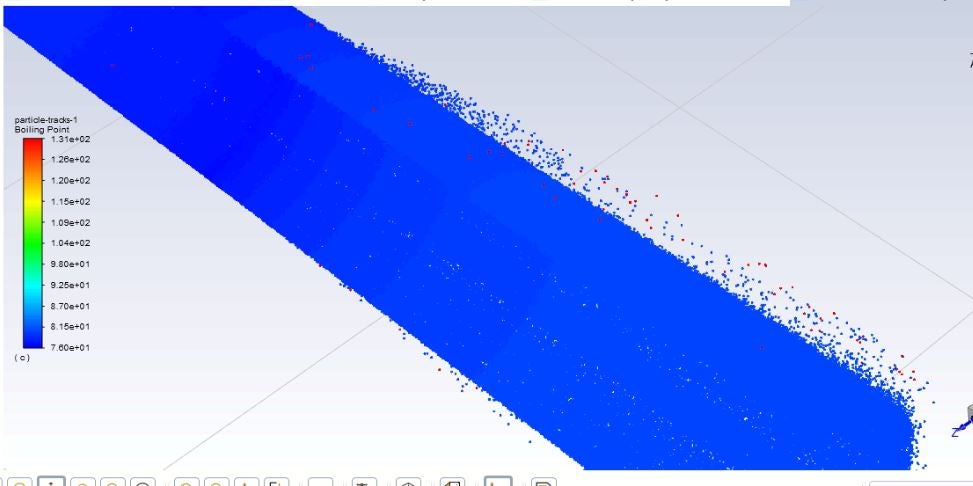

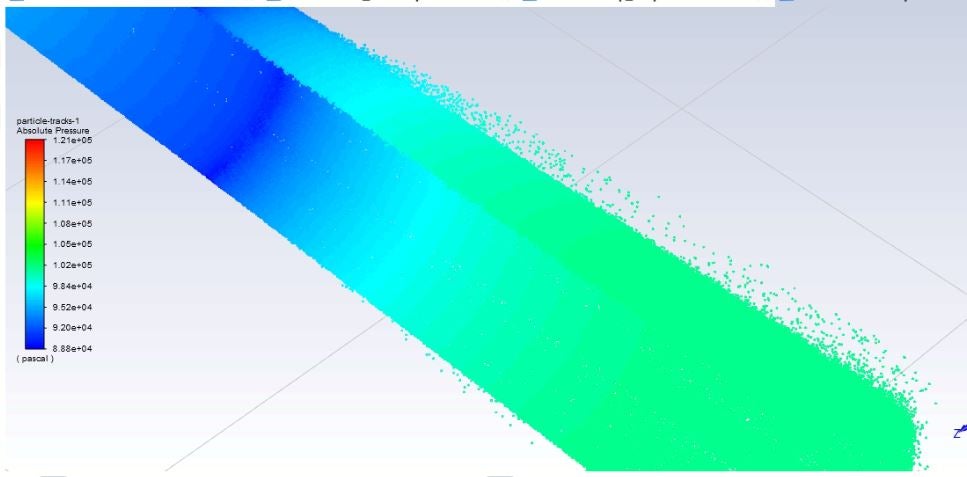

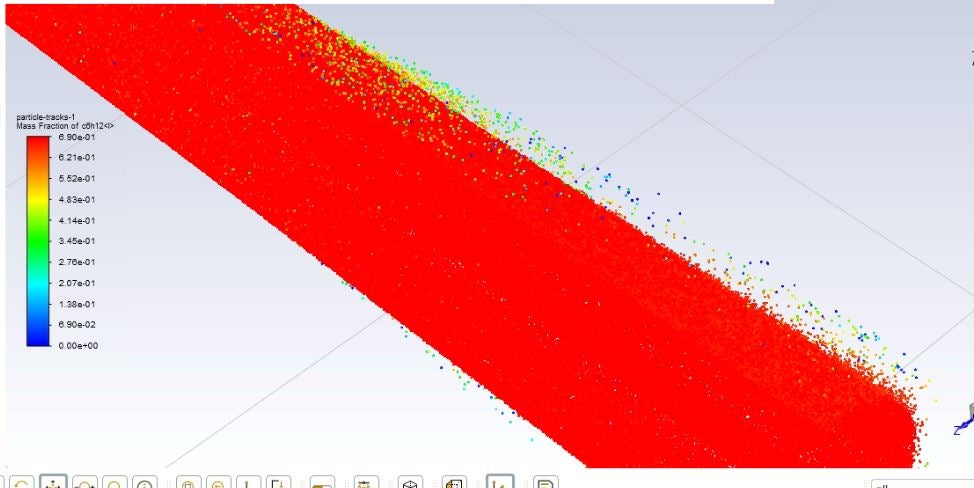

SubscriberI'm attaching the images showing the particle temperature, particle boiling point, particle pressure, and particle volatile component mass fraction (starts at 0.7). As you can see that the temperature of the particle is very high compared to the boiling point. So, I'm expecting very high evaporation but not seeing very little. I'm using steady-state as I need properties at the steady-state only. Will it help to do transient? I'm not sure what is it that I'm doing wrong here.

February 2, 2022 at 9:35 amAmine Ben Hadj Ali

Ansys EmployeeAgain the vapor pressure is used here for the mass transfer. Can you tell the related saturation pressure to that boiling temperature?

February 2, 2022 at 10:15 amBeb99

SubscriberThe saturation pressures at different temperatures are as follows:

60C for 0.5e5 Pa

80C for 1e5 Pa

106C for 2e5 Pa

146C for 5e5 Pa

184C for 10bar

For example, at 1e5 Pa, any temp higher than 80C should cause evaporation right???

February 2, 2022 at 12:35 pmAmine Ben Hadj Ali

Ansys EmployeeAgain the Multicomponent mass transfer laws are driven by pressure differences. If you Total Vapor Pressure (in your case only one component is volatile) is now smaller than absolute pressure->Evaporation.

February 2, 2022 at 1:18 pmBeb99

SubscriberSo, does that mean if I increase the pressure I should see evaporation???

February 3, 2022 at 3:48 amBeb99

SubscriberAlso, can you tell me how to get the mass flow rate of the discrete phase through a surface? I know we can do this for the continuum phase easily, but I couldn't find this for the discrete phase.

February 3, 2022 at 7:55 amAmine Ben Hadj Ali

Ansys EmployeeYou will need to do sampling along the zone surfaces or plane. Is not like an Eulerian Fluid: we have discrete particles.

Viewing 10 reply threads- The topic ‘Boiling point setting in DPM’ is closed to new replies.

Ansys Innovation SpaceTrending discussions- air flow in and out of computer case

- Varying Bond model parameters to mimic soil particle cohesion/stiction

- Eroded Mass due to Erosion of Soil Particles by Fluids

- Guidance needed for Conjugate Heat Transfer Analysis for a 3s3p Li-ion Battery

- Centrifugal Fan Analysis for Determination of Characteristic Curve

- I am doing a corona simulation. But particles are not spreading.

- Issue to compile a UDF in ANSYS Fluent

- JACOBI Convergence Issue in ANSYS AQWA

- affinity not set

- Resuming SAG Mill Simulation with New Particle Batch in Rocky

Top Contributors-

3862

-

1414

-

1221

-

1118

-

1015

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-