-

-

December 20, 2021 at 10:50 am

Larz_Johnston

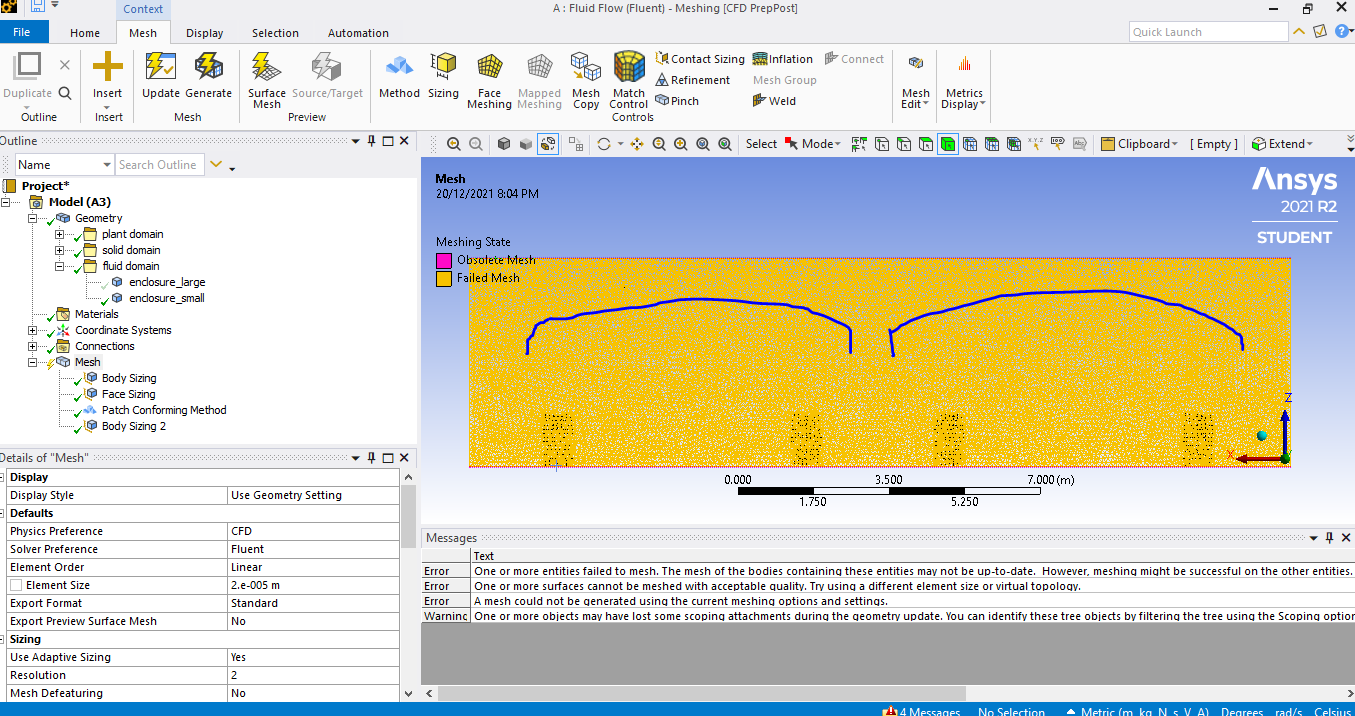

SubscriberI'm having a rather difficult time with this mesh:

December 20, 2021 at 11:50 amSaumadeep Choudhury

Forum ModeratorHi @Larz_Johnston

Mesh failure can occur because of the following reasons -

If the number of nodes and elements is more than 32K then there will be meshing failure since you are using student version software.

If the imported geometry has some issue, some of the material or features are missing, some information might have been skipped during the conversion of the file. Geometry should not have any errors before going to meshing. You can refer to this - Problems meshing ÔÇö Ansys Learning Forum

Minimum elemental size isnÔÇÖt small enough to have elements along any radius of curvature.

Meshing also fails due to overlapping surfaces or bodies present in the component. Hence, always check any assembly or part file for intersecting surfaces or merge features, respectively.

You can also refer to this - How to resolve Mesh Failure ÔÇö Ansys Learning Forum

Regards, Saumadeep

Ansys Help

Ansys Learning Forum (Rules & Guidelines)

December 21, 2021 at 8:43 pmLarz_Johnston

SubscriberThese are good. I'm trying out some attempts to find which of these is the issue:

attempting to suppress every other geometry and increase the element size is not working, so presumably either having too many cells is not the problem, or by the time element size is large enough to go under it creates a new problem of a different sort

I've attempted every kind of repair I know how to operate in spaceclaim. the one that turns curves into planes will probably wind up being pretty helpful in future versions but none of them turned up any issues this time.

I attempted to remove curvature by turning the arc along the top into a set of planes, but could it be having trouble with corners? I don't really have any sharp angles to suspect, but if anything like that was the cause of the issue then shouldn't I expect for the geometry making the corner to have the same problem (since it's just an inverse of the area causing the problem)?

I've attempted to find intersecting bodies with the tools in spaceclaim (interference specifically), but have not found anything.

So in short I have no idea what the problem is. But here's what I understand; the issue occurs in the smaller of two rectangular prism-shaped enclosures, which houses four rectangular prisms and on more complex shape that approximates a shade-cover held in an arc. The arc is 0.2 mm thick, which makes me think that the size is causing the issue, yet the arc meshes just fine and the prism surrounding it fails. could it be that the 0.2 mm edges of the enclosure are where it's failing? Because I tried to add inflation around those edges and it still didn't work.

December 22, 2021 at 9:28 amRob

Forum ModeratorIf you mesh the volume that fails first? Pick the volume & right-click Mesh selected body. Depending on the mesh that's put onto the 0.2mm thick section it may be the facets on the thin face that are causing the problems. As you're then going onto Fluent, I'd also read up on "thin walls" and "coupled walls" as we can apply a thickness to a thin wall for heat transfer and therefore don't always need to mesh it.

December 22, 2021 at 10:29 amLarz_Johnston

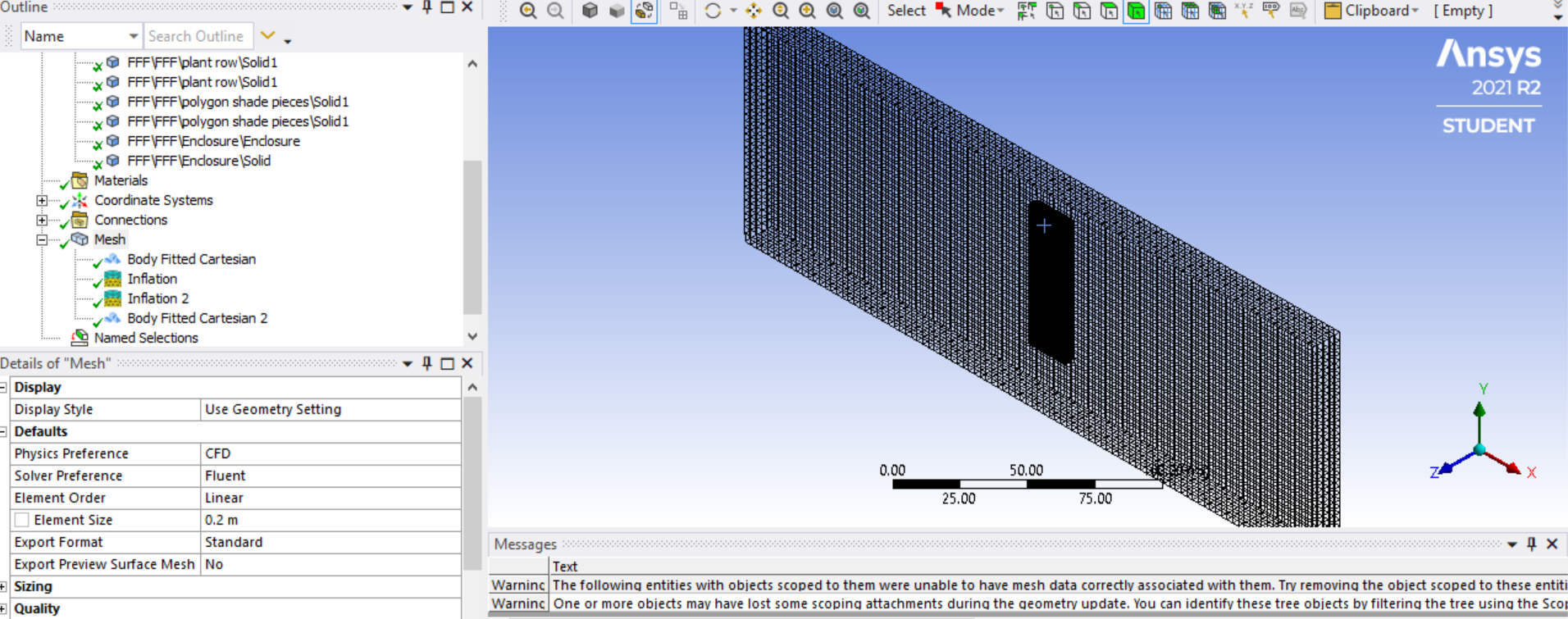

SubscriberOkay... I've changed the method to cartesian and added inflation around the edges (not sure if that second one helps because I did it first, it didn't work, then I changed it to cartesian and slightly decrease element size). It has helped somewhat: the mesh gives me a message for the enclosure still: "The following entities with objects scoped to them were unable to have mesh data correctly associated with them. Try removing the object scoped to these entities or try another mesh method to get a successful mesh. Project>Model>Geometry>FFF\FFF\Enclosure\Solid>FFF\FFF\Enclosure\Solid", and it still shows the 'please update' symbol in workbench while failing whenever I try to update, but the mess is not failing now.

Do I still need to do something, or can I move onto the fluent solver at this point?

Do I still need to do something, or can I move onto the fluent solver at this point?

December 22, 2021 at 10:55 amRob

Forum ModeratorWhat's the cell quality like? Have you adequately resolved the areas of interest?

December 22, 2021 at 11:22 amLarz_Johnston

SubscriberIf by cell quality you mean that the size of the elements should be able to accurately get results, then I believe so. And the area of interest was the smaller enclosure with the thicker mesh. It still has one error message but is able to complete the mesh without failing (the second error in the image is from yesterday). I'm really not sure if that is sufficient or not, and to see whether or not its enough I'll really need the process explained like I'm a child, since I constantly feel like I'm missing a lot of background knowledge for using this program whenever I get on this forum.

EDIT: I removed the inflation and the error message disappeared. Now it's a "One or more objects may have lost some scoping attachments during the geometry update. You can identify these tree objects by filtering the tree using the Scoping option set to Partial. Project"). Actually going through what it says just has an empty display with nothing to interact with in the model space.

December 22, 2021 at 3:44 pmRob

Forum ModeratorElement size will determine whether you pick up the flow features and gradients. Cell quality is whether the cells are approximately the right shape to ensure you get a valid (or any) result. Both are covered in the tutorials to some extent (click on Help to access these.

Viewing 7 reply threads- The topic ‘Meshing issue: identifying the cause of a failed mesh’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

5104

-

1831

-

1387

-

1248

-

1021

Top Rated Tags© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.