-

-

December 13, 2021 at 4:33 am

musaero19

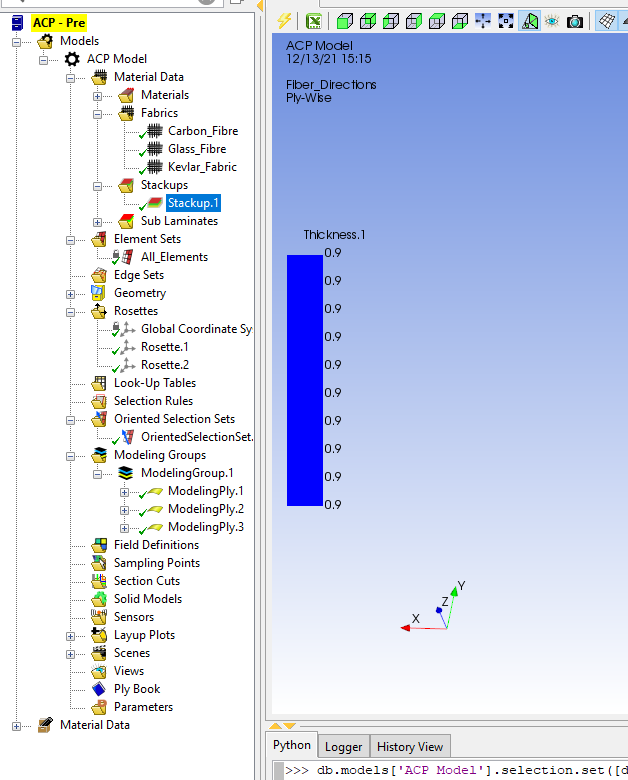

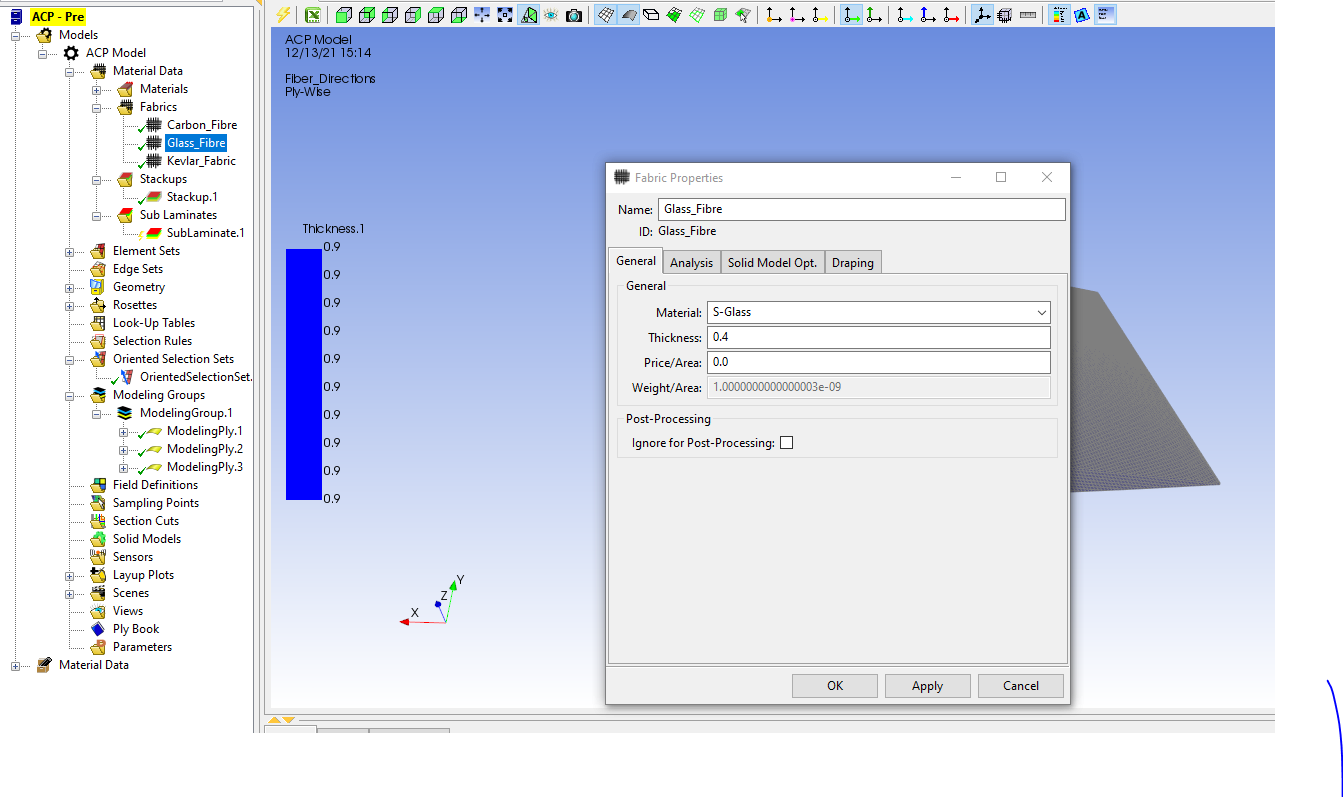

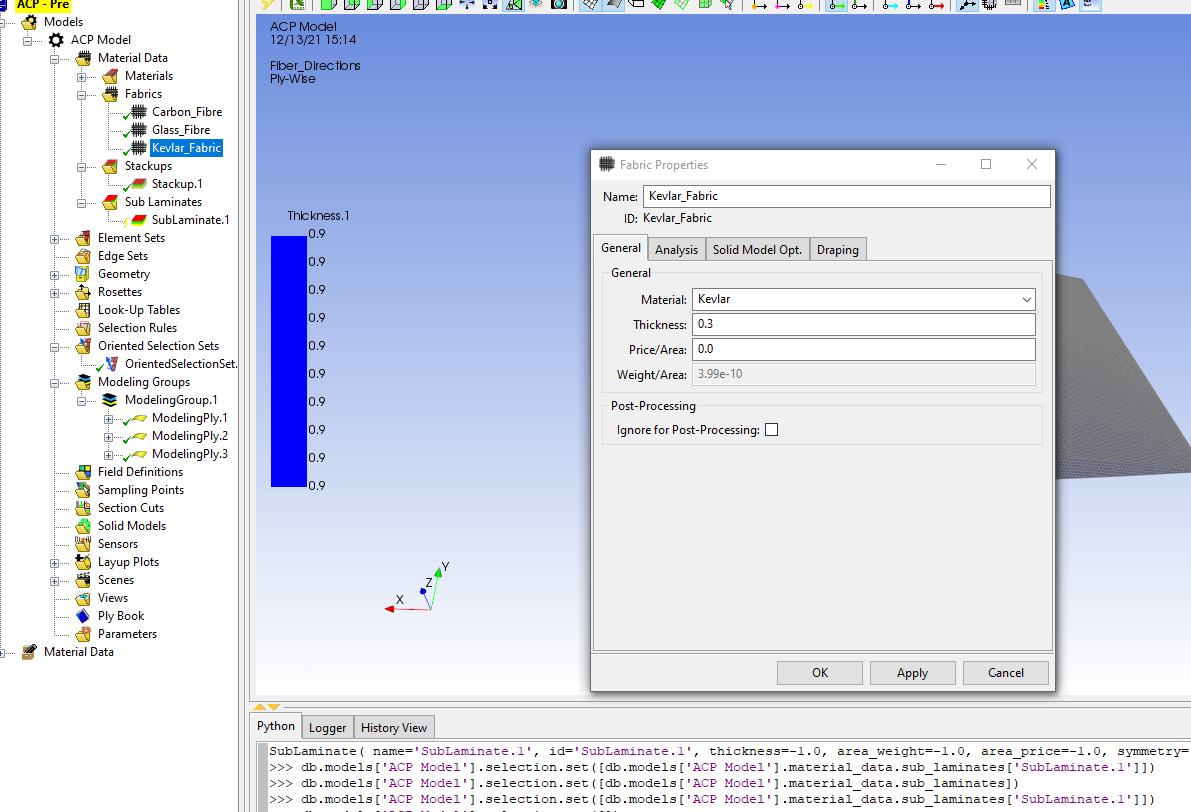

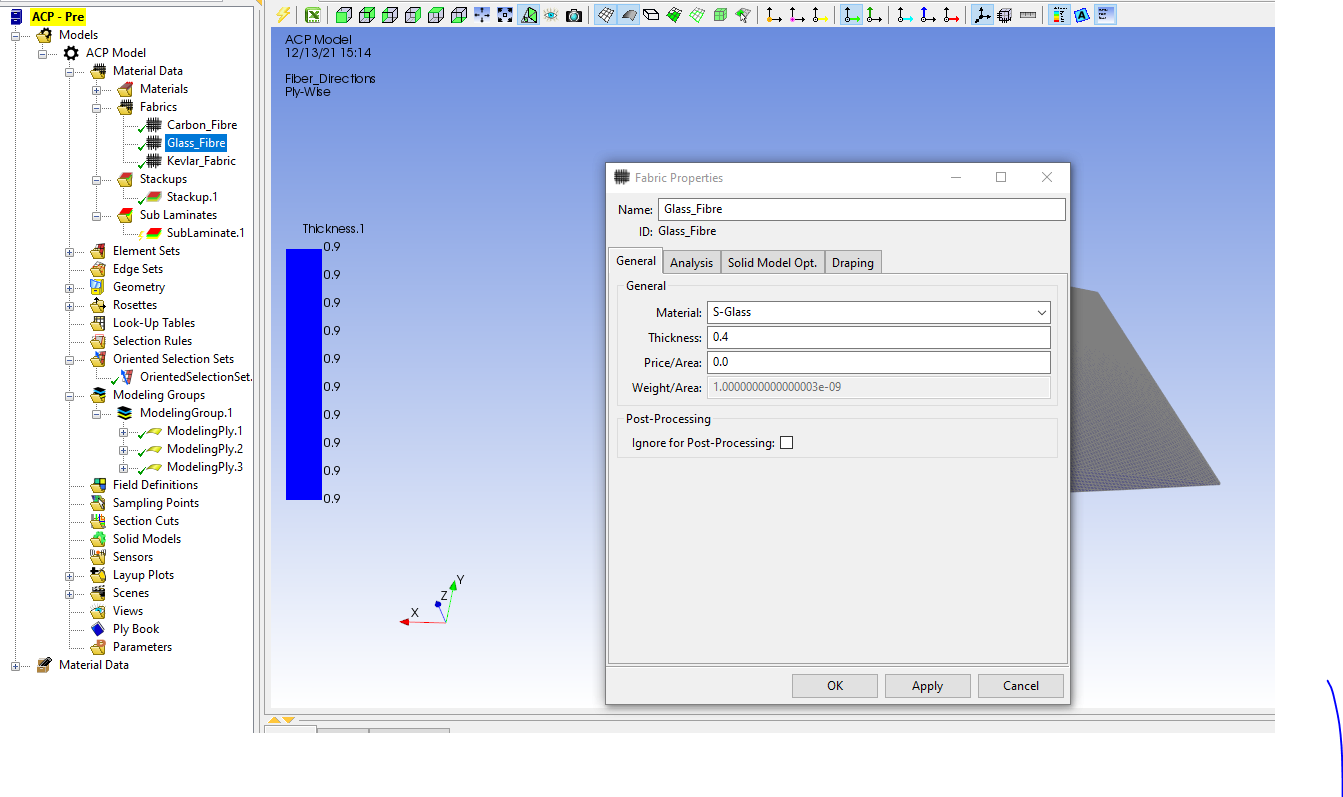

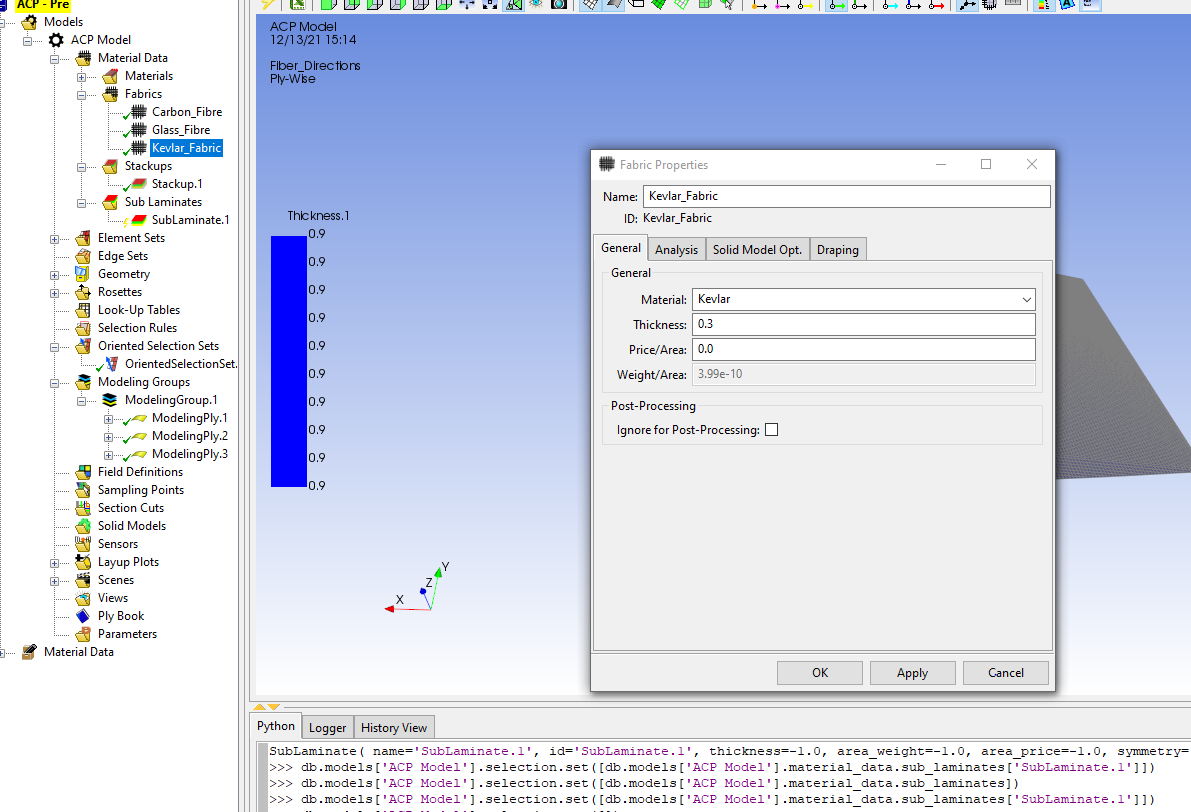

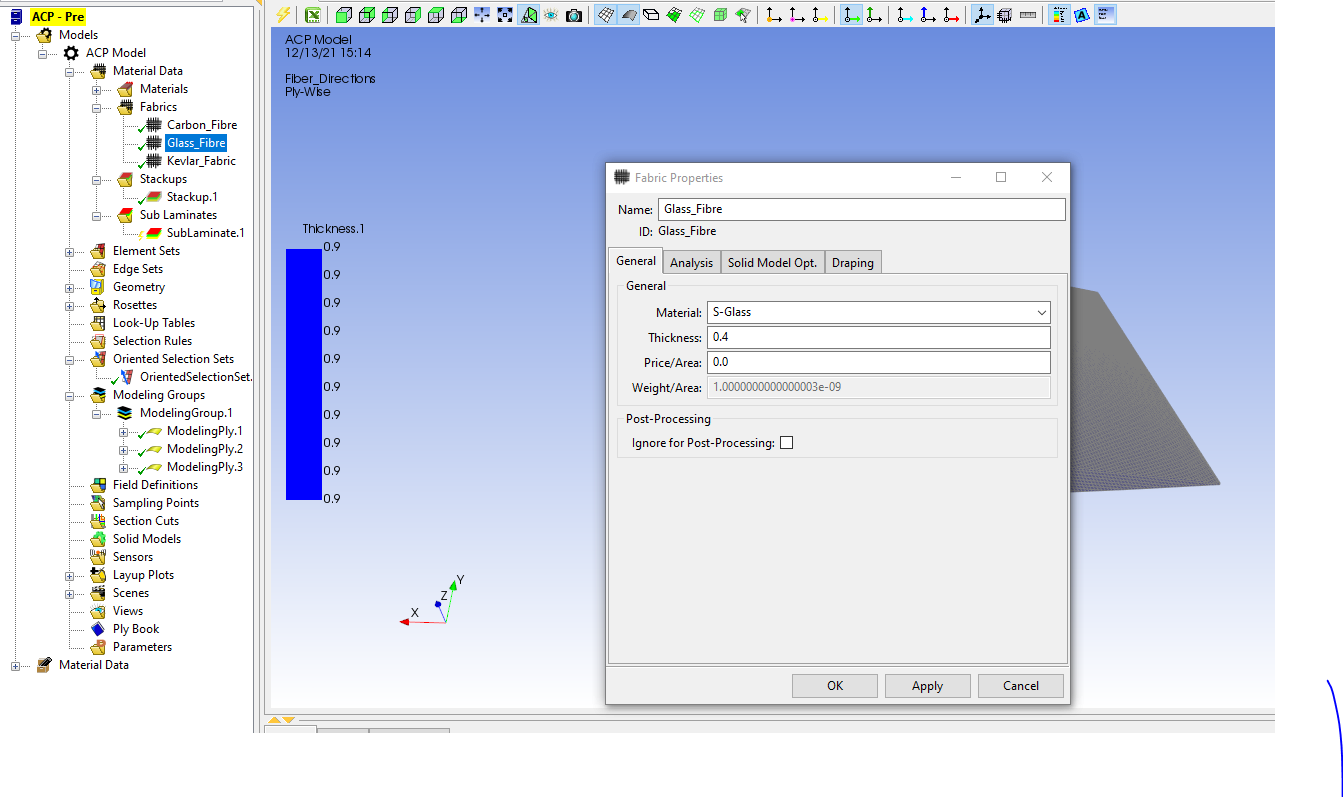

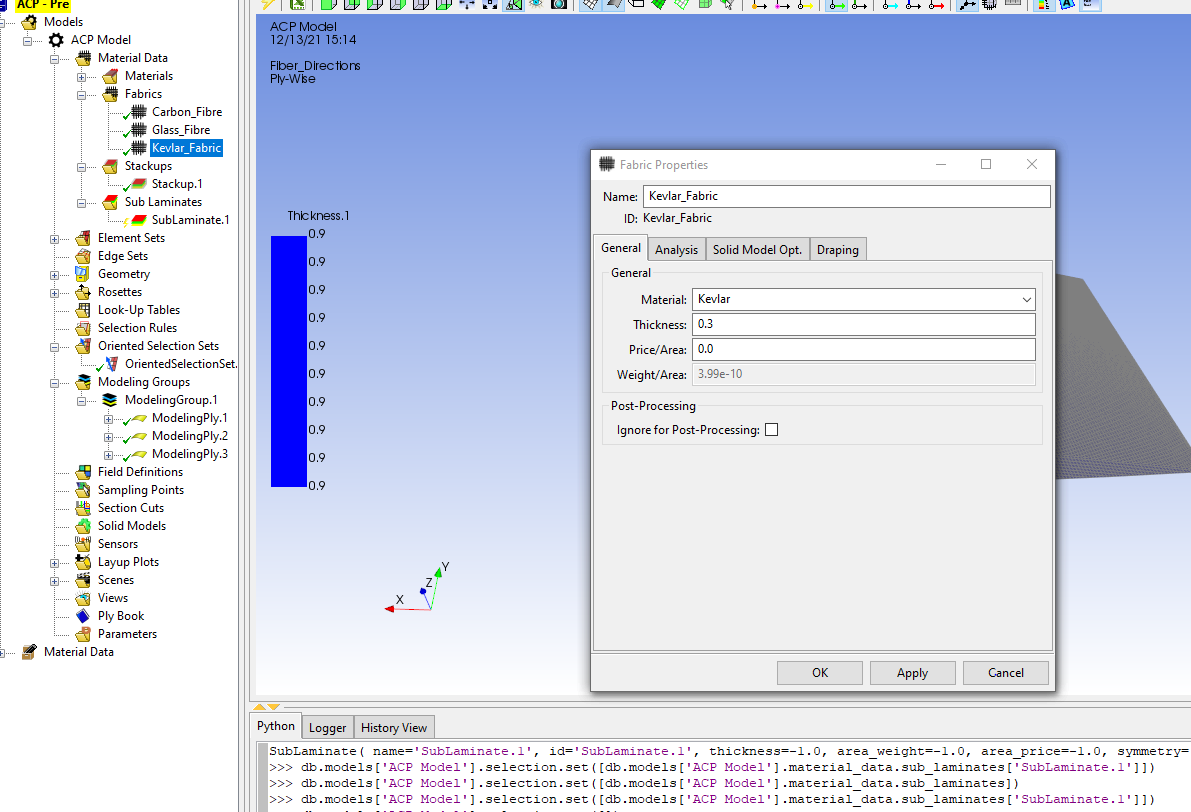

SubscriberThe skin is made up of 3 composite materials. S-glass, Aluminium and Kevlar. The aluminum skin is 0.4 mm in thickness with top layer while the glass fiber skin is 1mm in thickness made of 5 layers arranged in a symmetrical layup [±45/0/±45]. Kevlar with 0.4 mm thickness with 1 layer.

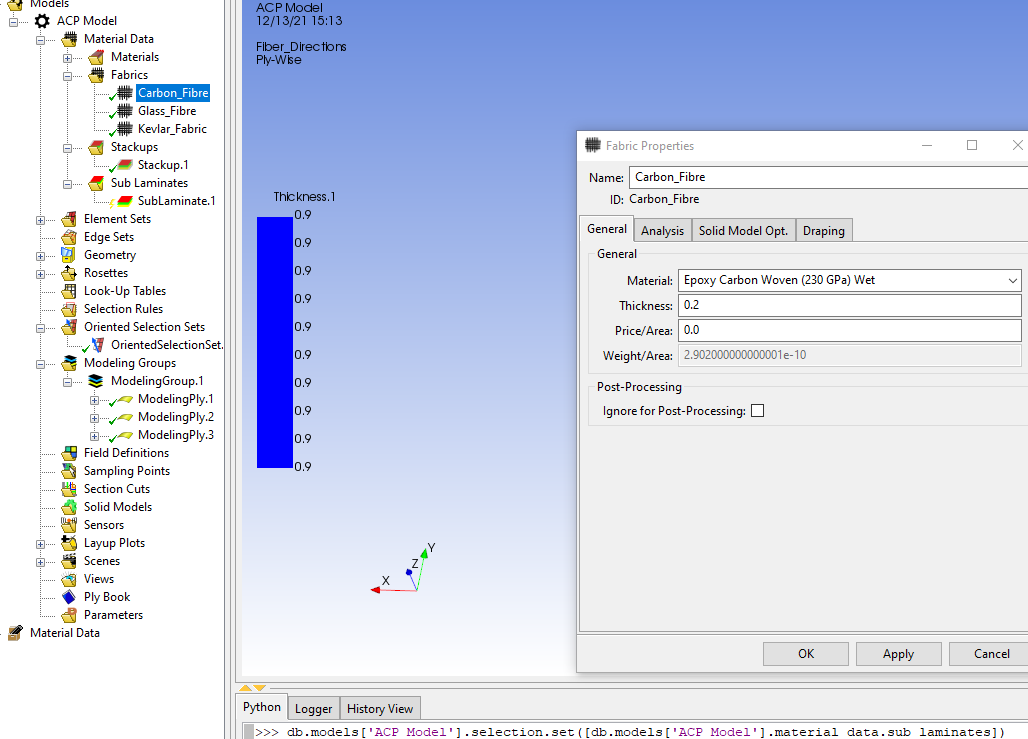

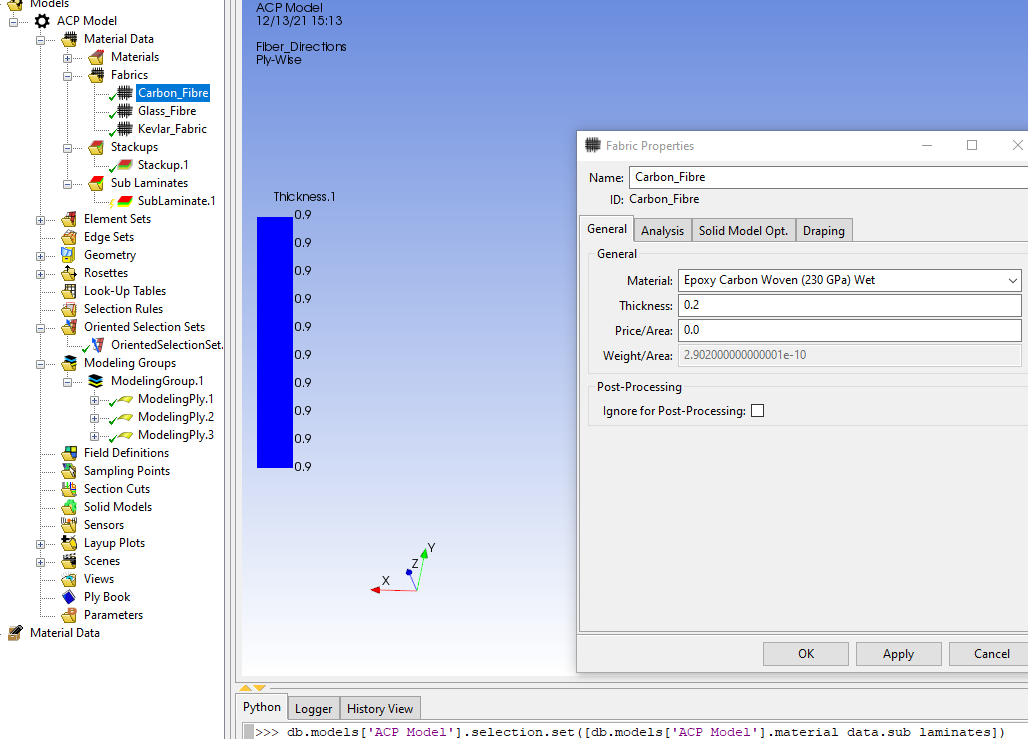

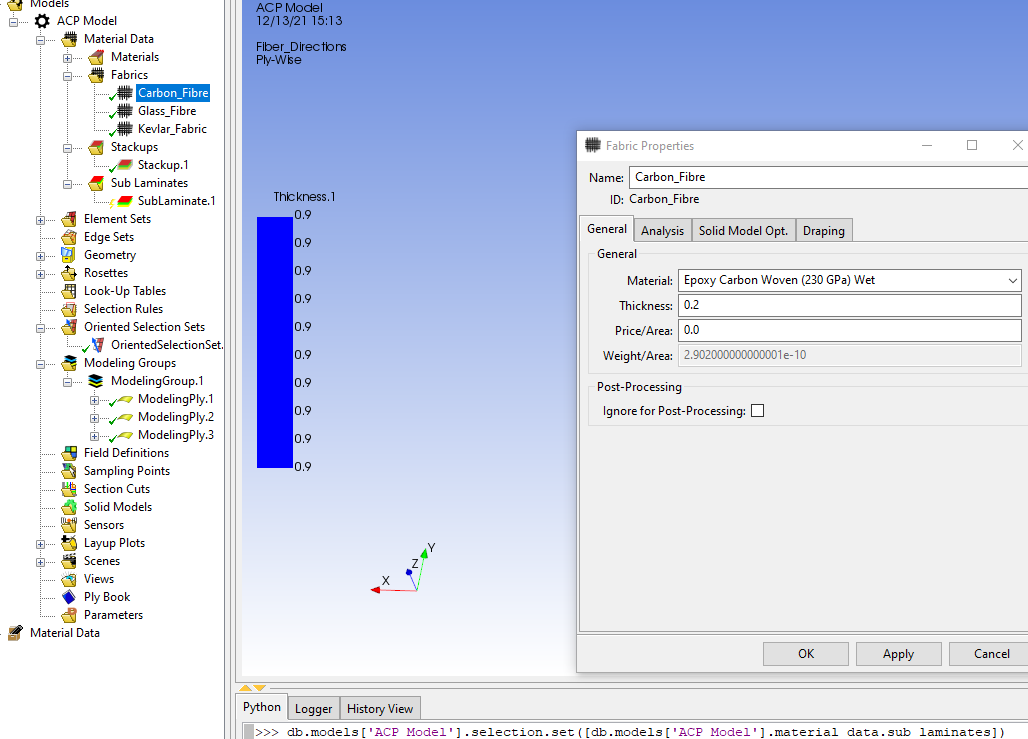

In ACP, I CREATE 3 Fabrics for these three materials.

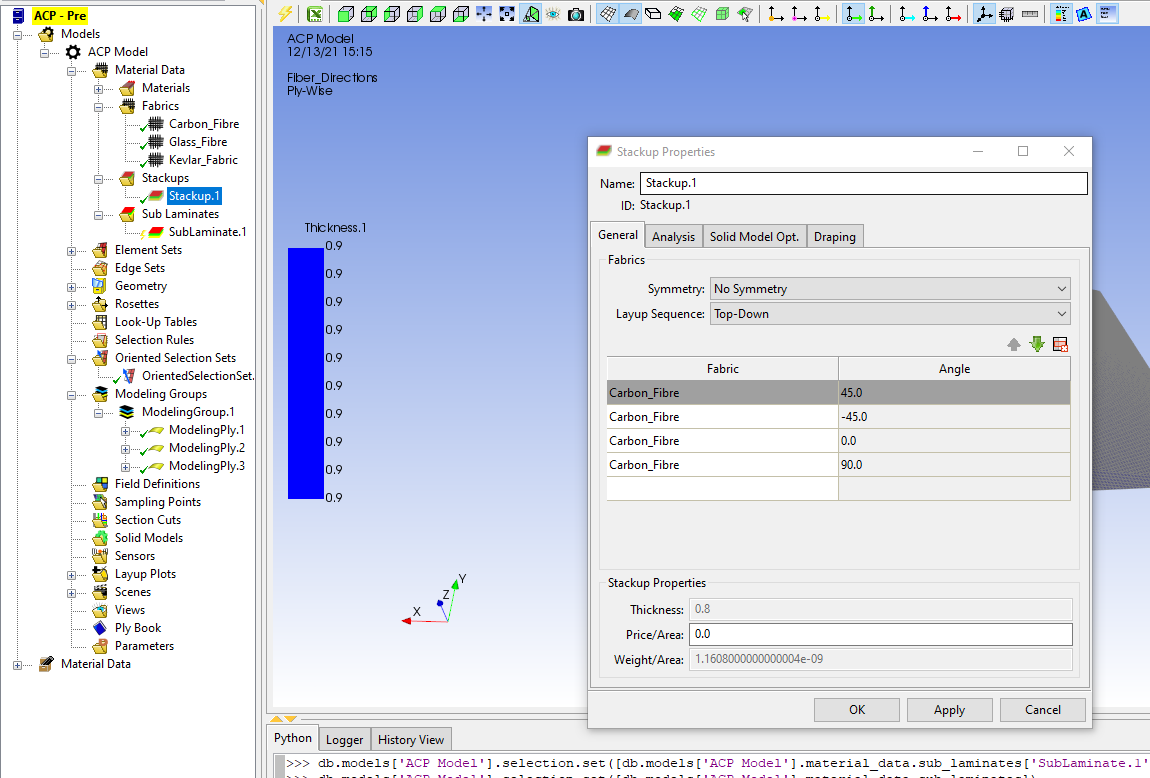

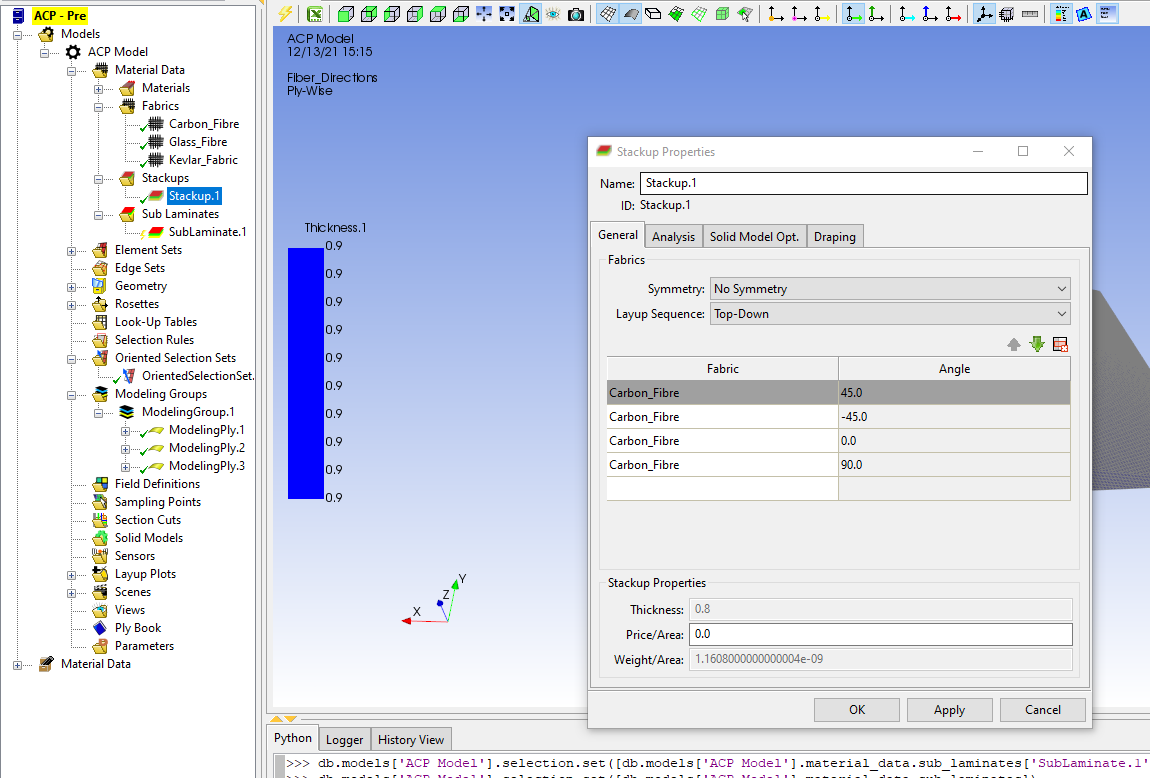

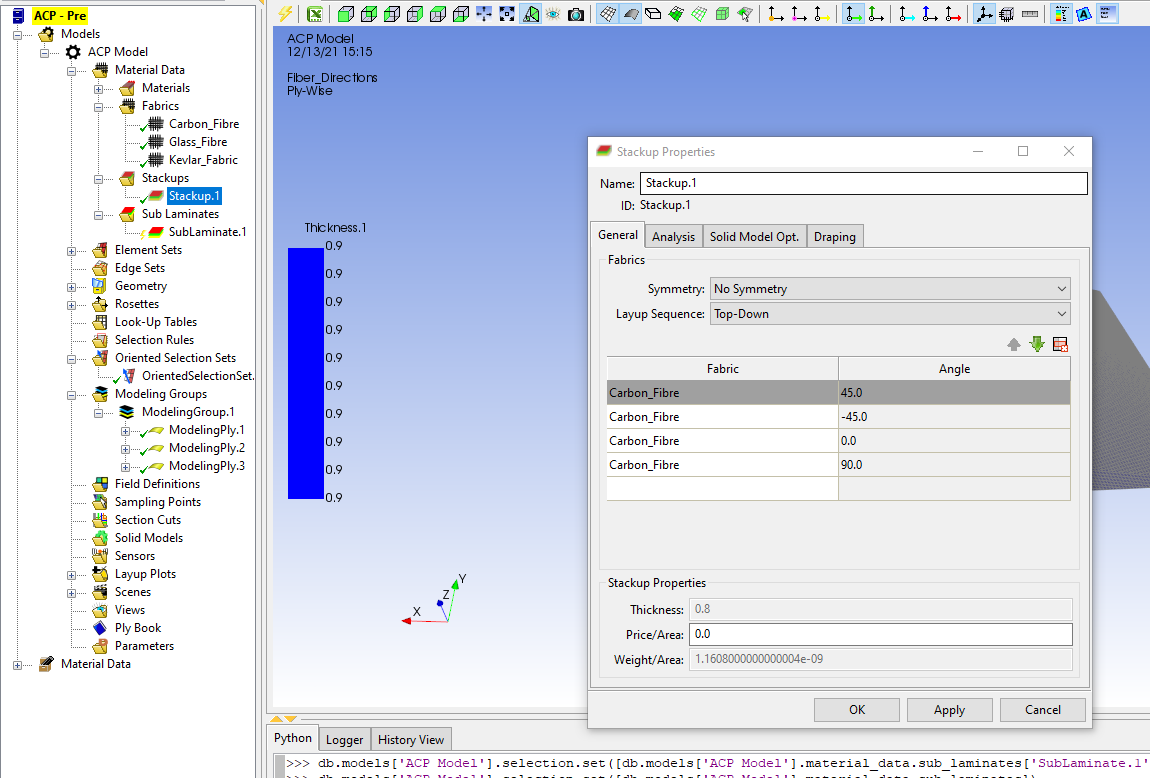

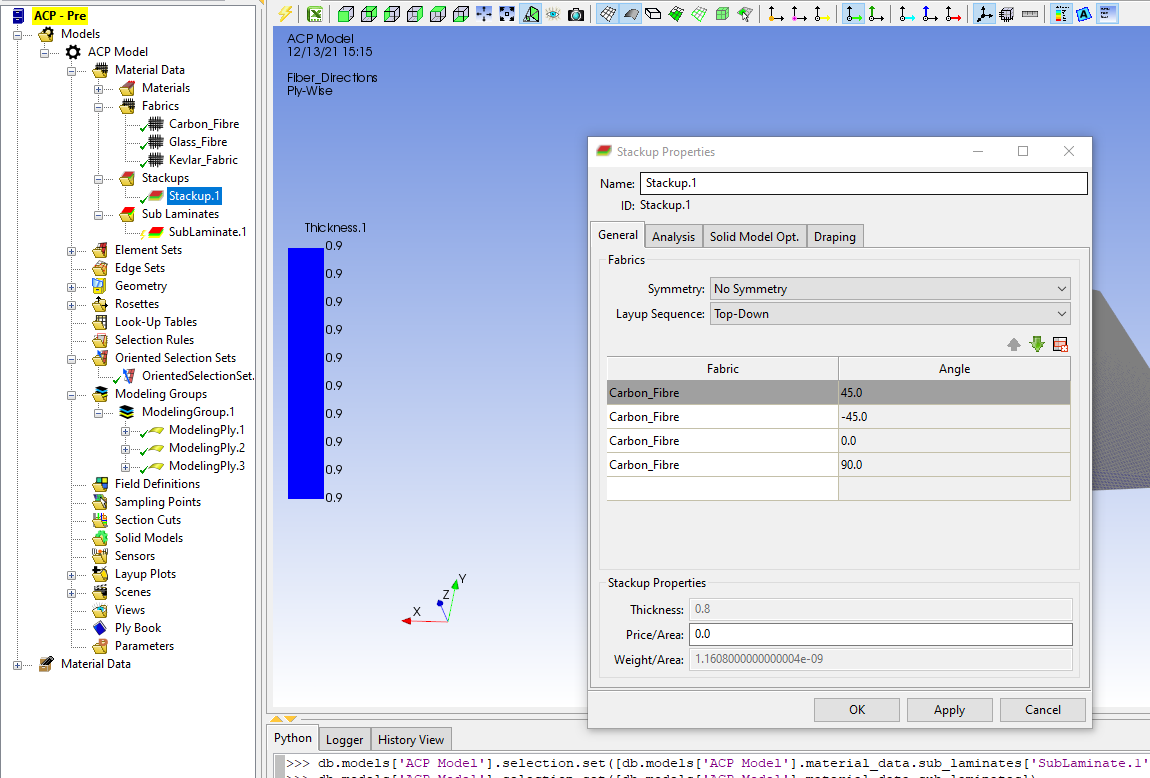

Then, I CREATE Stack-ups for Fabric material glass to give it directions [±45/0/±45].

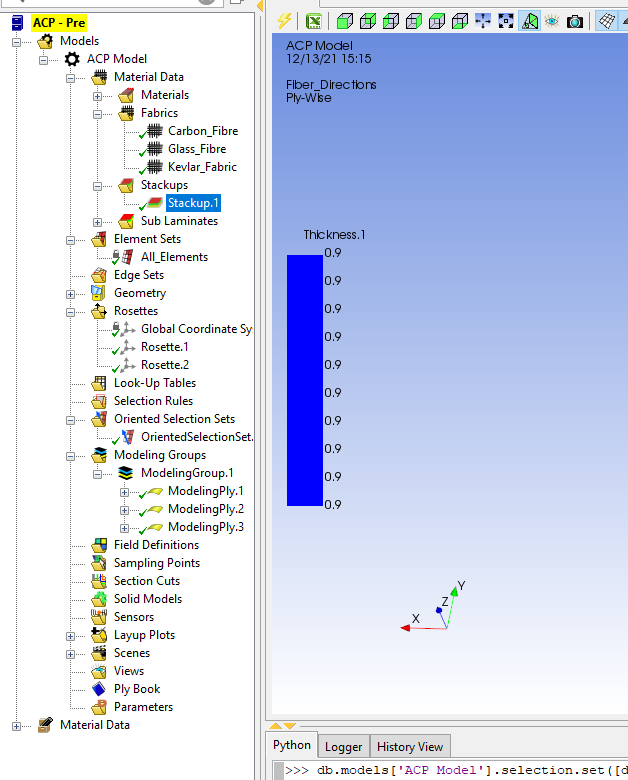

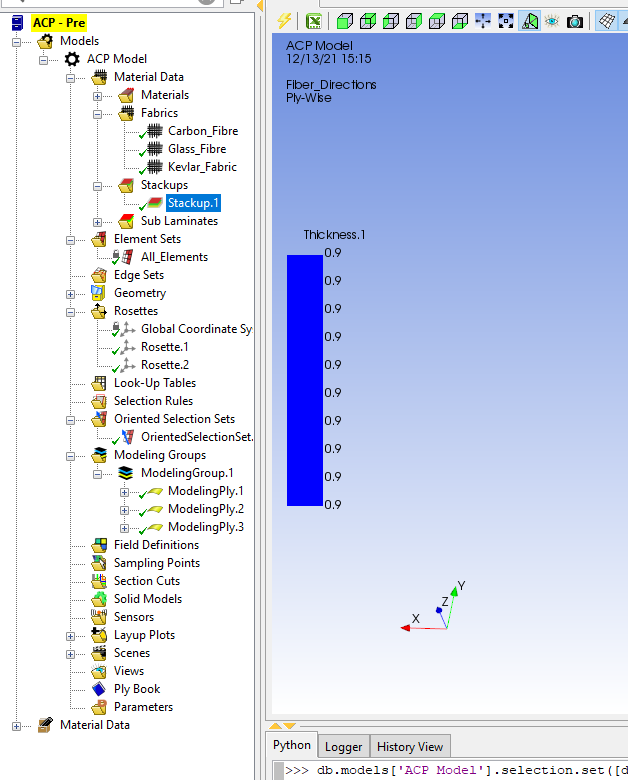

Then, I do Rosettes followed Oriented Selection sets.

Then, Modelling Groups to create Ply layers.

I want to know whether

December 13, 2021 at 2:38 pmGovindan Nagappan

Ansys EmployeeSince already created the stackup for glass, you can use that to build the modeling plies. Select the fabric for aluminum ad kevlar and use the stackup for the glass. You do not have to create sublaminates.

(If you have a set of layers repeating in your model, you can create sublaminates and use that to build the modeling plies.)

December 13, 2021 at 8:21 pmmusaero19

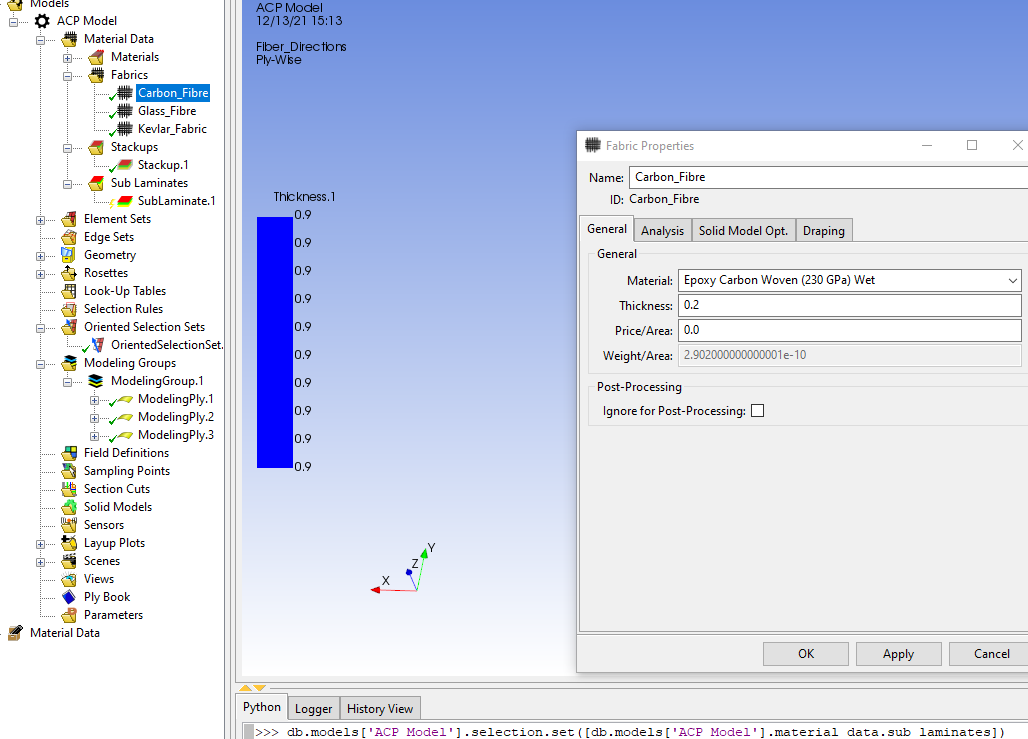

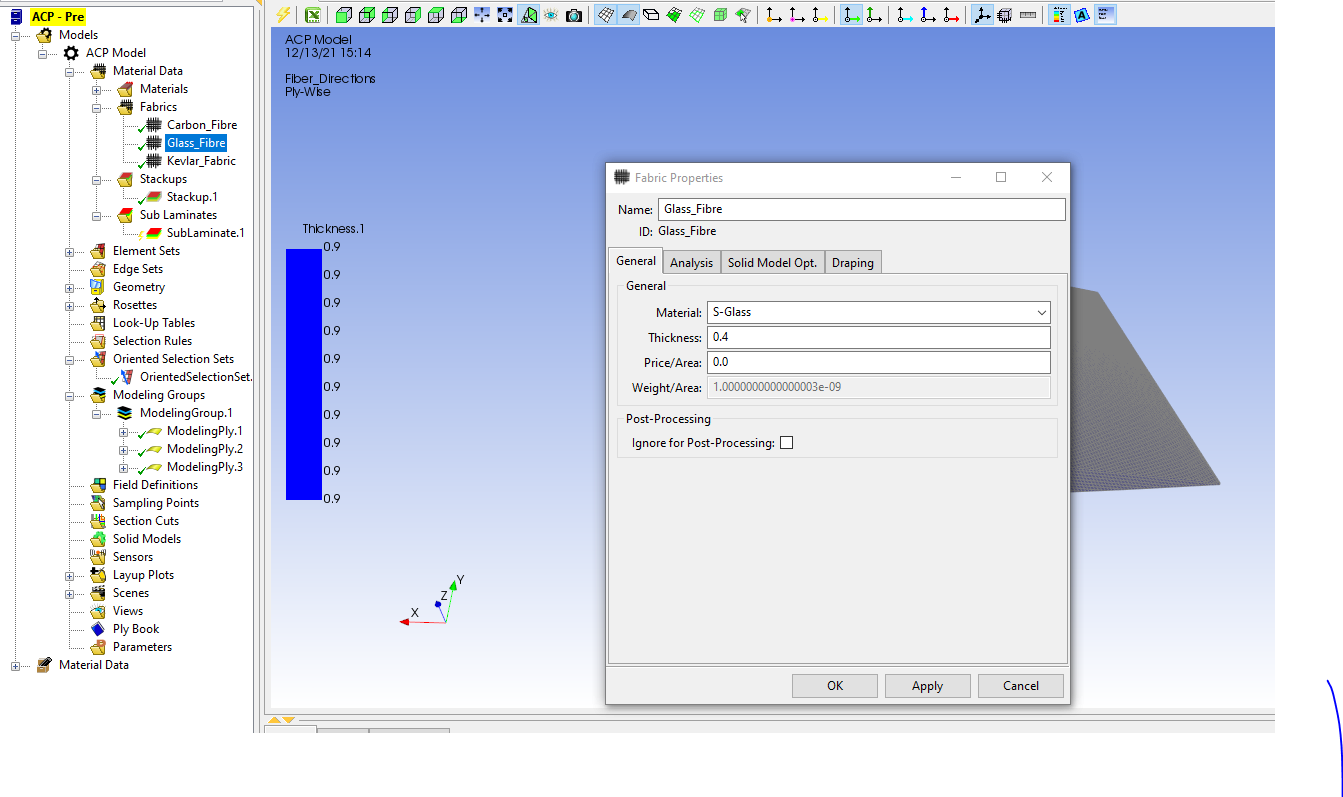

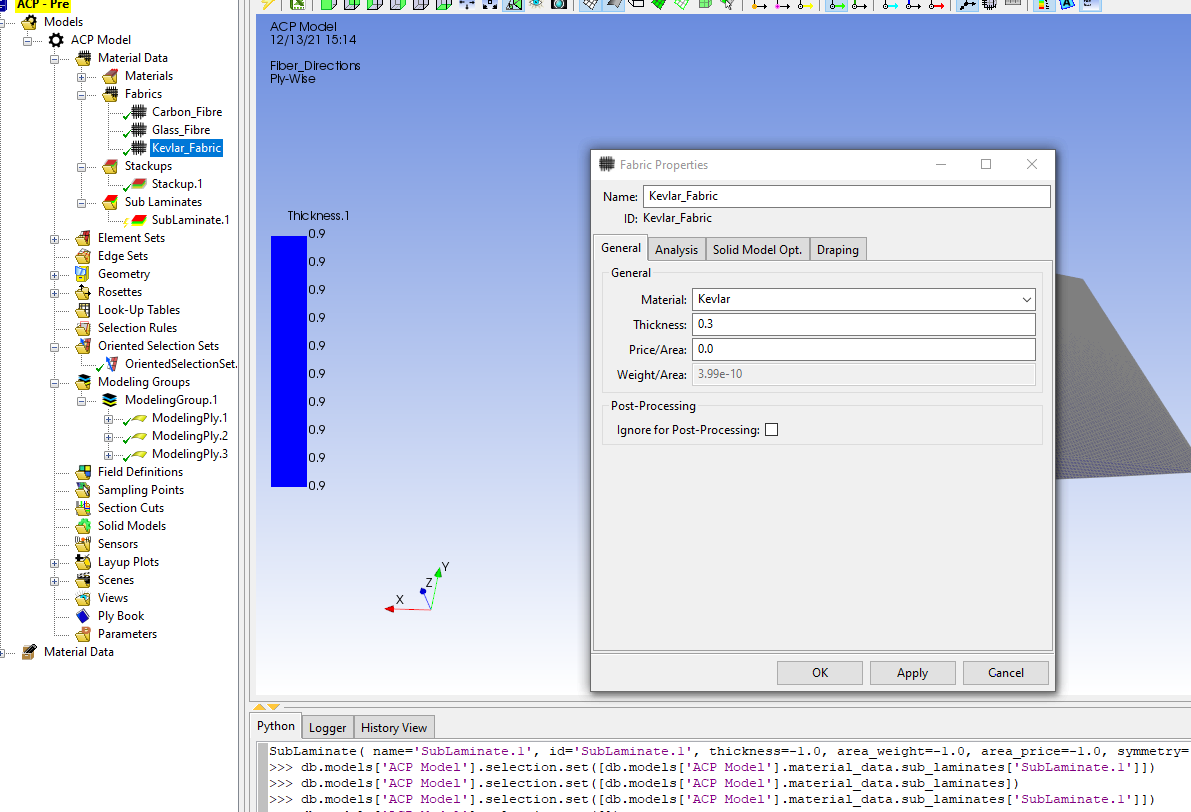

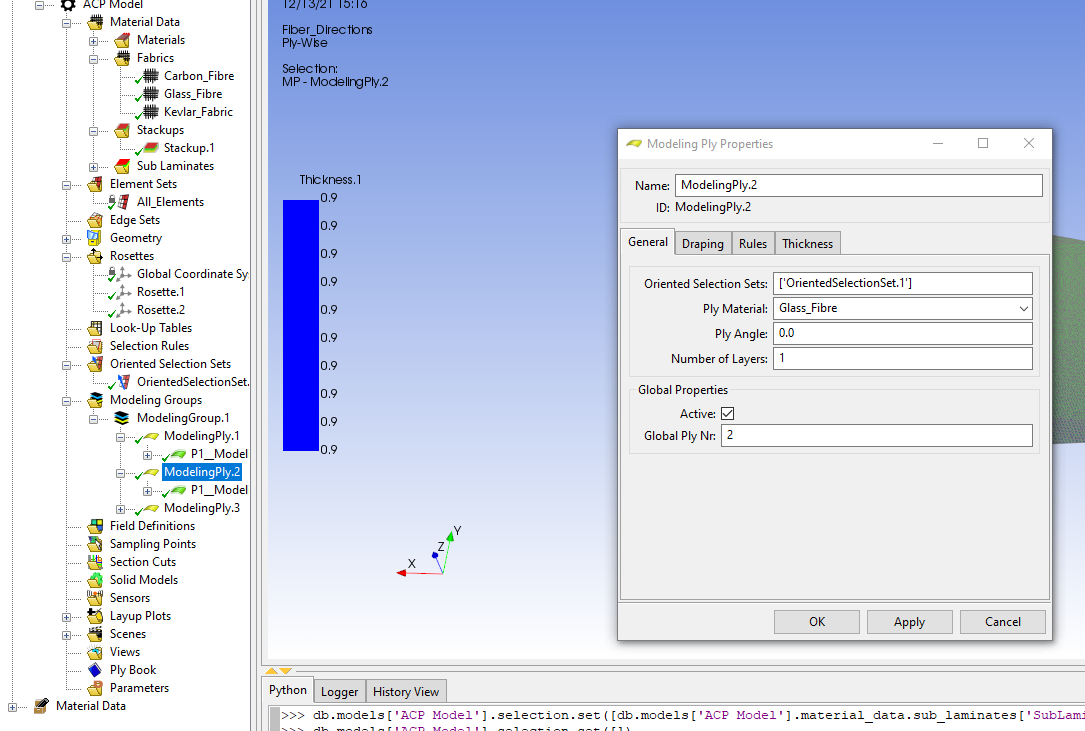

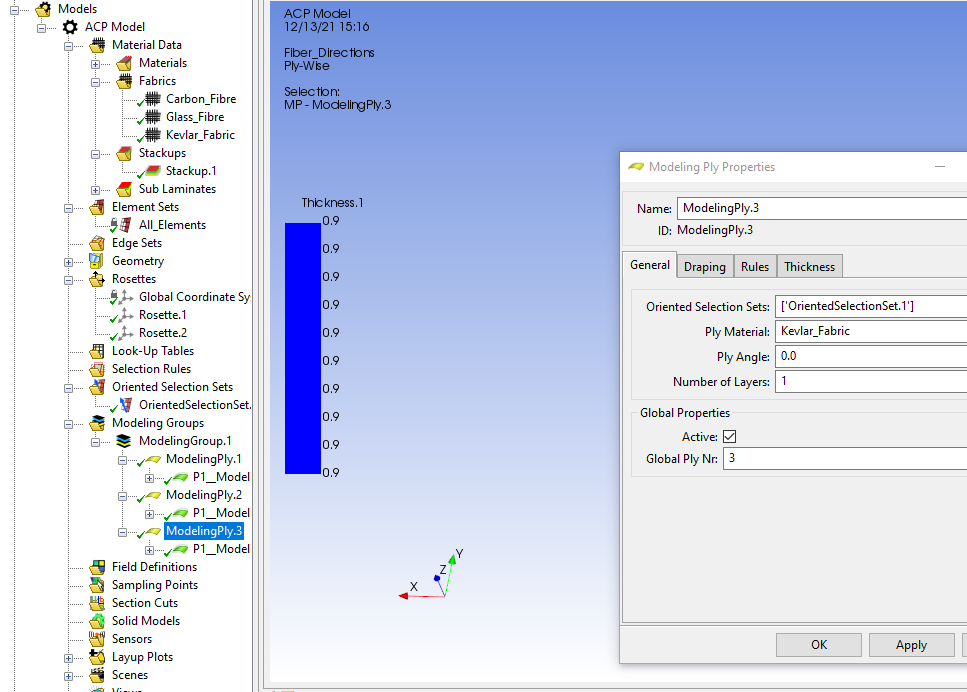

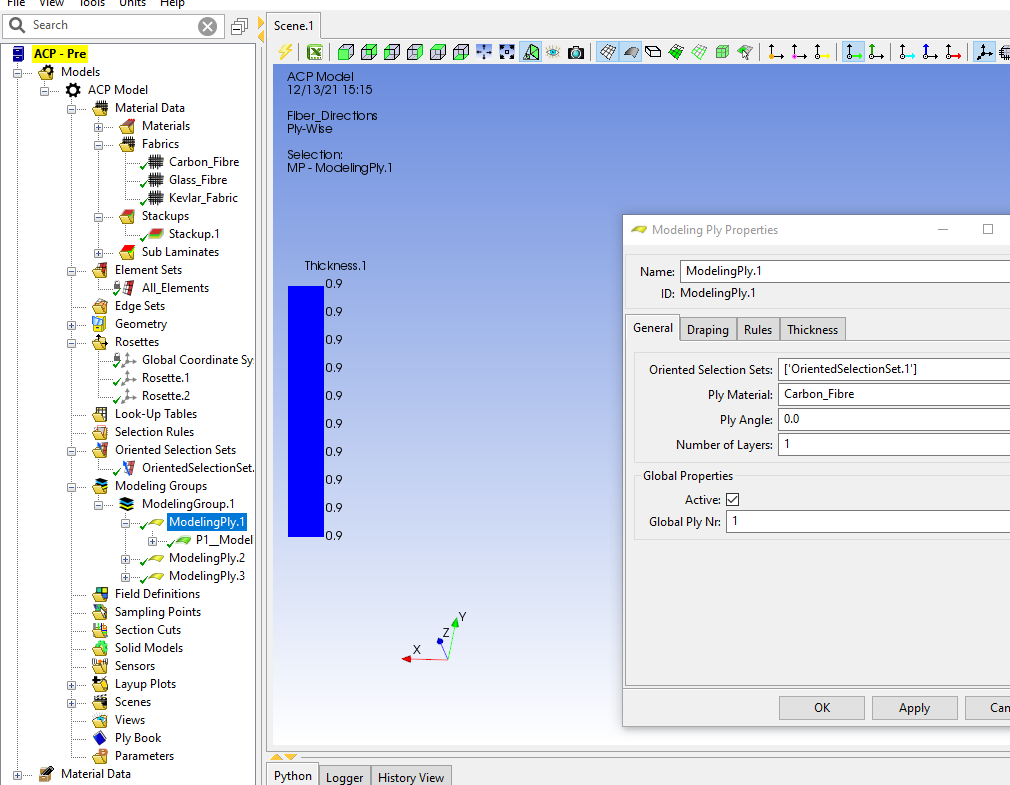

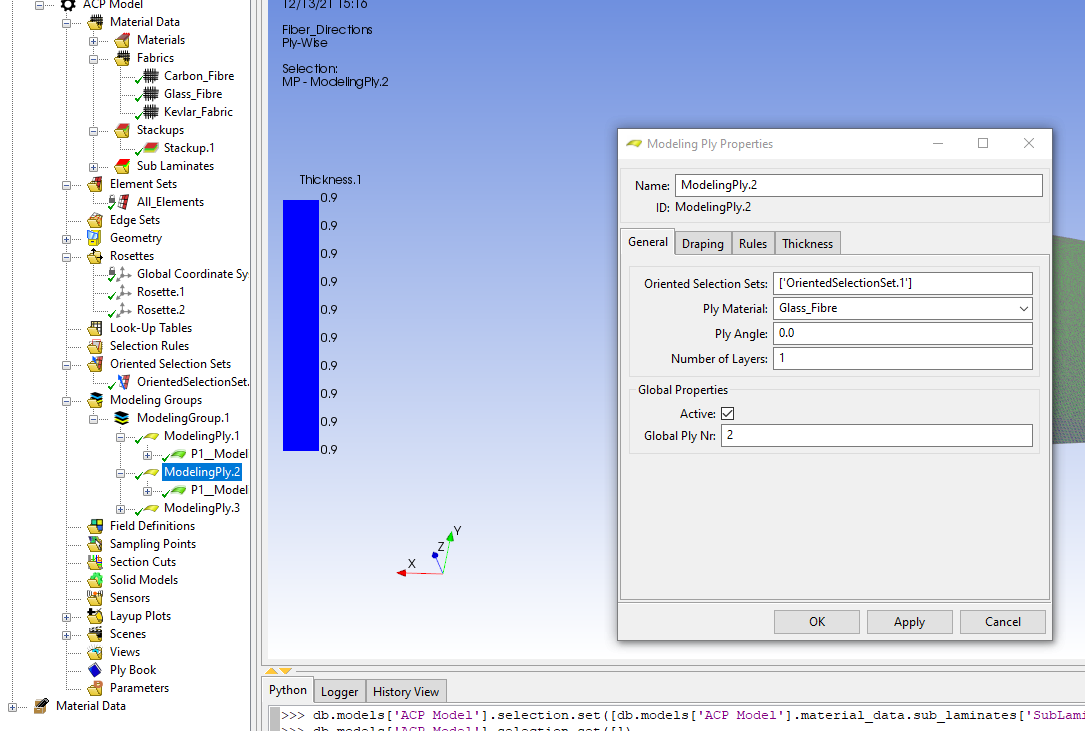

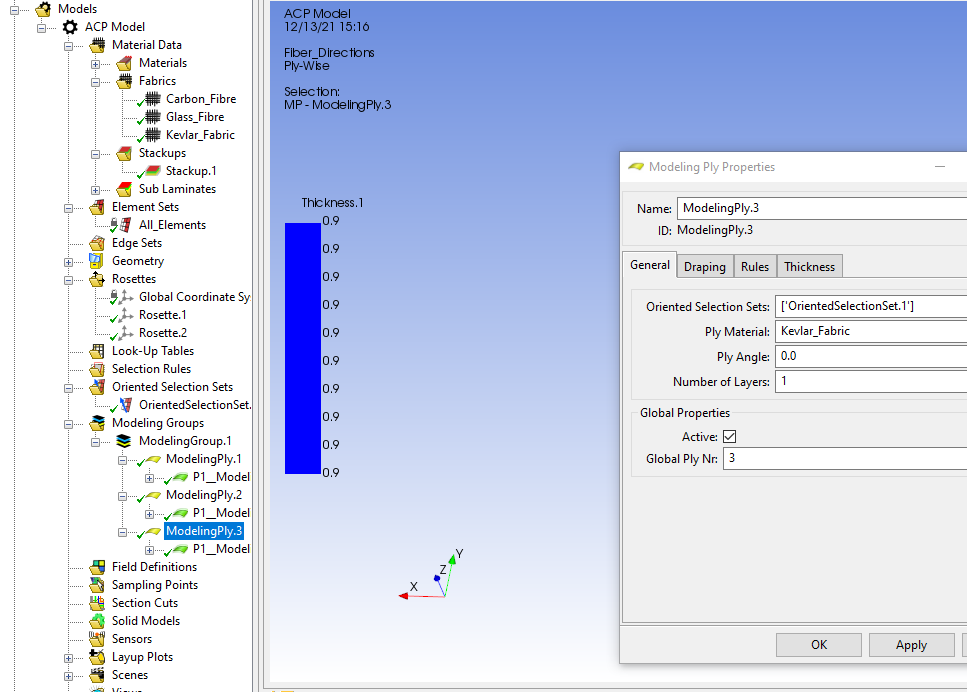

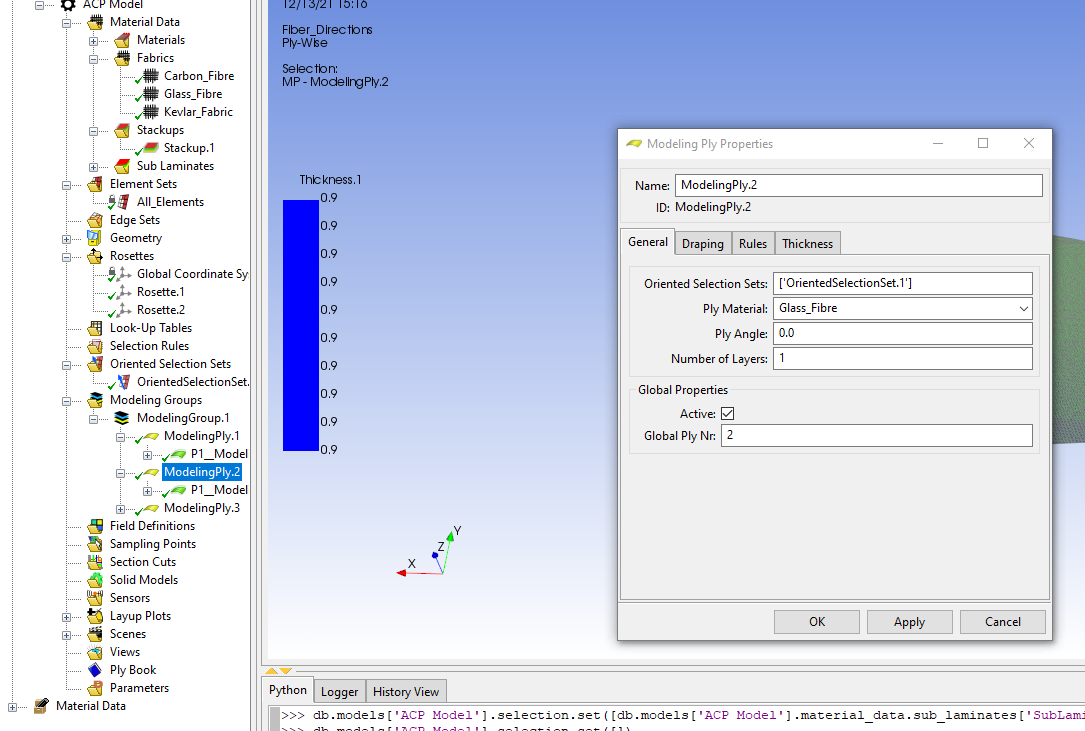

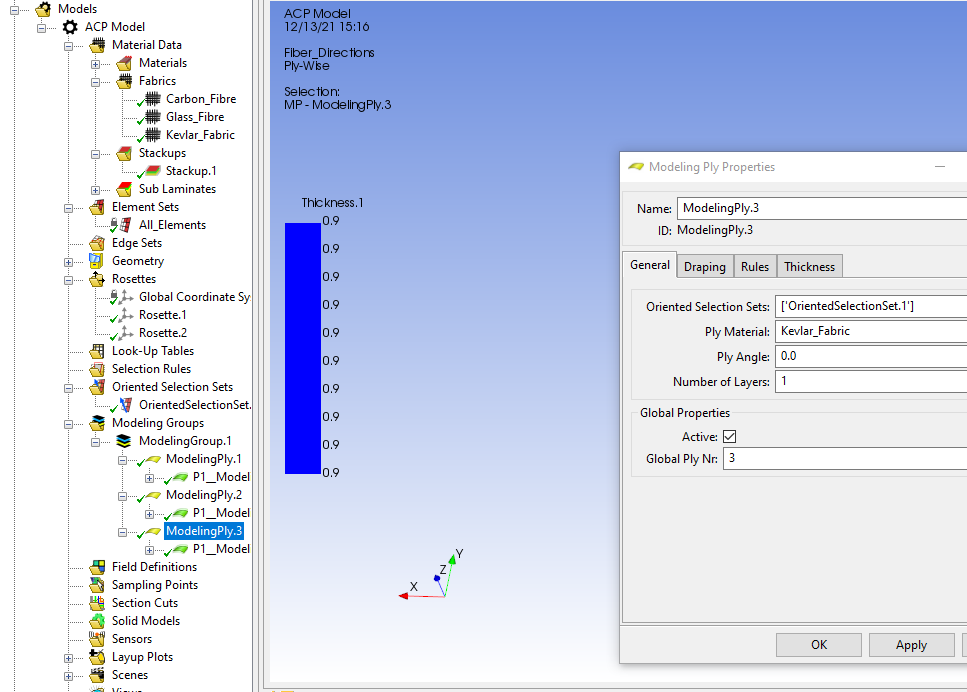

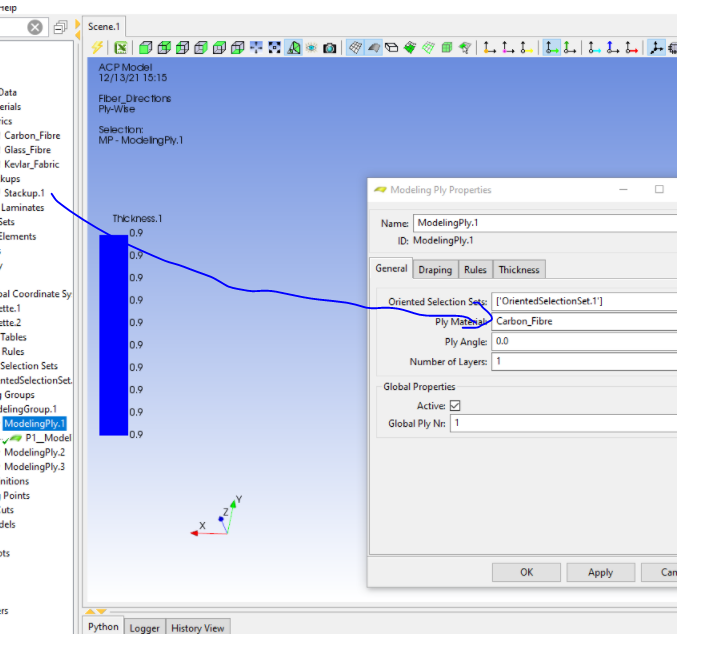

SubscriberHi Gnagapp Thank you for your feedback. I am following the same sequence, but I am not sure of the final composite thickness and geometry. I am using 4 layers of carbon with 0.2 (for example), glass 0.4mm and kevlar 0.3mm, i am getting total thickness 0.9mm. I am attaching sequence pictures. Kindly help accordingly. Thank you.

December 13, 2021 at 8:50 pmGovindan Nagappan

Ansys EmployeeDecember 13, 2021 at 8:54 pmDecember 13, 2021 at 8:55 pmDecember 13, 2021 at 8:55 pmDecember 13, 2021 at 8:55 pmDecember 13, 2021 at 8:55 pmDecember 13, 2021 at 8:55 pmDecember 13, 2021 at 8:55 pmDecember 13, 2021 at 8:55 pmDecember 13, 2021 at 8:57 pmmusaero19

SubscriberI have attached the pictures above. If you need any additional info, please let me know

thank you

December 14, 2021 at 4:07 pmGovindan Nagappan

Ansys Employeemusaero19

Your modeling groups have the following ply material: 1. carbon fiber(0.2 thickness) 2.glass fiber (0.4 thickness) 3. kevlar fabric (0.3 thckness) - so total thickness is 0.9

If you need multiple layers of carbon fiber, use the stack up for ply material (this has 4 layers). so total thickness will be 1.5

December 15, 2021 at 5:28 pmDecember 15, 2021 at 5:28 pmDecember 15, 2021 at 5:28 pmDecember 15, 2021 at 5:44 pmmusaero19

SubscriberThank You. Noted. Solved the issue.

April 8, 2022 at 10:21 amjdeep8

SubscriberTo the original poster im conducting somewhat similar kind of analysis but having some difficulties in material designation ,in my case im just conducting the experiment on kevlar .

I saw in the image you posted above the material kevlar fabric , i wasnt able to find it in my fabrics section.

can you help me regarding this?

April 8, 2022 at 3:51 pmmusaero19

SubscriberHi jdeep Kevlar is not on the engineering material list. You have to add it by inserting material properties. You can search any paper and check the material properties you want. Then add a new engineering material kevlar and then use it accordingly. Thank you.

June 12, 2023 at 5:27 pmZaid Abd Al-Hadi

SubscriberHey musaero19

How can you define the resulting composite material by only defining fiber and matrix materials?

(i.e. if I defined the fabrics; fiber and matrix individually, how then the resulting lamina will be defined,

how to define the volume fraction and fiber diameter?)Viewing 20 reply threads- The topic ‘How to create Composite layers in ACP’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

4843

-

1587

-

1386

-

1242

-

1021

Top Rated Tags© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

Ansys Assistant

Welcome to Ansys Assistant!

An AI-based virtual assistant for active Ansys Academic Customers. Please login using your university issued email address.

Hey there, you are quite inquisitive! You have hit your hourly question limit. Please retry after '10' minutes. For questions, please reach out to ansyslearn@ansys.com.

RETRY