-

-

November 3, 2021 at 9:29 am

fabrypiro

SubscriberHi Guys,

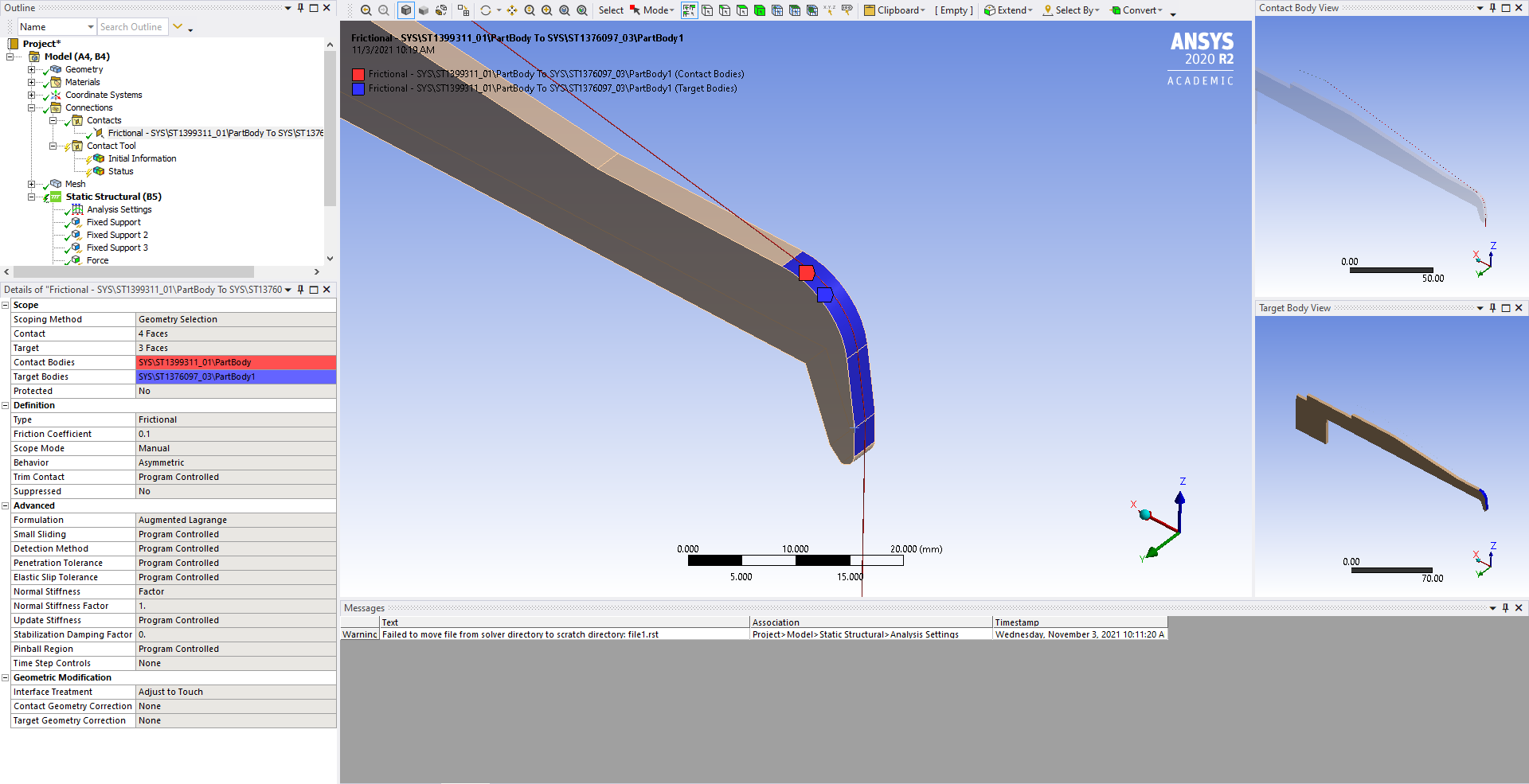

I am having difficulty in converging the following static structural analysis:

it is a frictional contact between a steel support structure and a tungsten wire. The wire, fixed at the ends (fixed support), is stretched by an upward force of 15N, while the support structure is also fixed with a fixed support.

The purpose of the analysis is to understand the effective contact area between the surfaces and the pressure applied by the wire on the support.

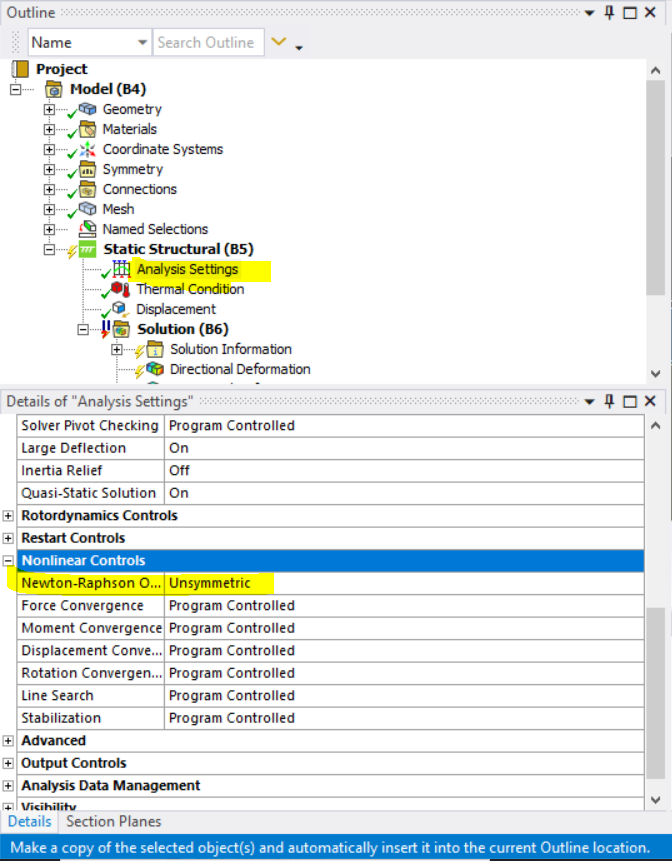

I attach some images where you can view the contact parameters and the analysis settings that I have assigned. I think these are the crucial for achieving convergence.

November 5, 2021 at 4:16 pmNovember 9, 2021 at 8:53 amfabrypiro

SubscriberHi Amaniyar thank you so much for the support. I'm trying to get the convergence with the settings you suggested.

For the physical convergence of the results I thought of proceeding in this way, maybe you can give me your opinion:

now I am launching analysis with a coarse mesh to have a not too heavy model and to be able to quickly manage the mathematical convergence;

Subsequently, the objective of the analysis is to calculate the effective contact area between the wire and the support, the contact pressure and the frictional stresses. For this I think that the mesh in the contact area is crucial, so I will have to improve it. Also, I think contact stiffness is another parameter to manage for physical convergence.

The question I ask myself is: "what is the real contact area?" I think I have to run the analysis with different normal stiffness values ÔÇïÔÇïand see when the results converge with little deviation from one analysis to the next.

Do you think this is a good way to proceed?

Thanks again

Fabry

November 10, 2021 at 1:47 pmAkshay Maniyar

Ansys Employee

What do you mean by physical convergence? Do you want to check the variation of results w.r.t. the mesh size? If that is the case you can use adaptive convergence. I have attached the Ansys how to video which explains the adaptive convergence technique.

Also, starting with coarser mesh is good practice. But, you will have to use finer mesh in contact region between wire and support for proper contact.

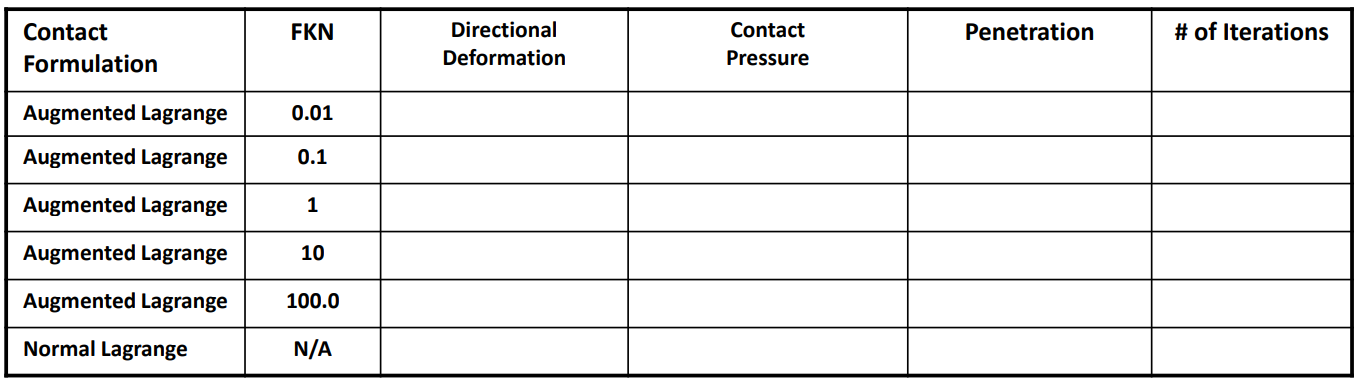

Normal stiffness value is actually a multiplier or a factor(FKN). If normal stiffness value is low, then penetration will be high but it will be easy for convergence. What you can try to do is change FKN as 0.1, 1 , 10 , 100 and record the results like contact pressure, penetration, directional deformation and decide which FKN is best for your application. (I have attached a table for your reference)

You can choose the best combination in terms of accuracy and number of iterations for your problem. Specifying the right contact stiffness is highly problem dependent. If localized contact-related results are unimportant, then the program controlled defaults might be acceptable.

You can choose the best combination in terms of accuracy and number of iterations for your problem. Specifying the right contact stiffness is highly problem dependent. If localized contact-related results are unimportant, then the program controlled defaults might be acceptable.

Thanks Amaniyar

November 25, 2021 at 3:10 pmfabrypiro

SubscriberHi Amaniyar I have just returned to work on this analysis; now it converges without too many problems and in a short time. Your suggestions were really helpful.

But now I have another problem concerning the accuracy of the results:

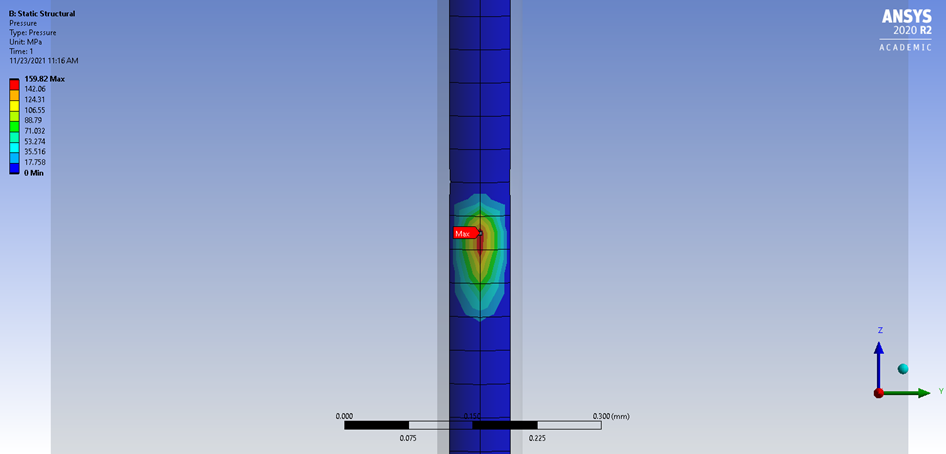

I am modeling a frictional contact between the two surfaces (wire and support) and what I should get as a result is a certain distribution of pressure on the contact surface. However, it happens that stresses are concentrated in a very localized area and the rest of the area is not in contact. By monitoring the elements in contact with the contact tracker, I realize that as soon as the sub-switches converge, I have a sharp decrease in the elements in contact.

Below you can see a plot of the contact pressure:

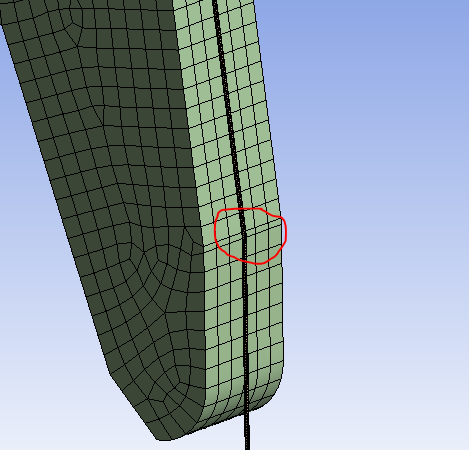

The pressure concentration zone is the one highlighted in red:

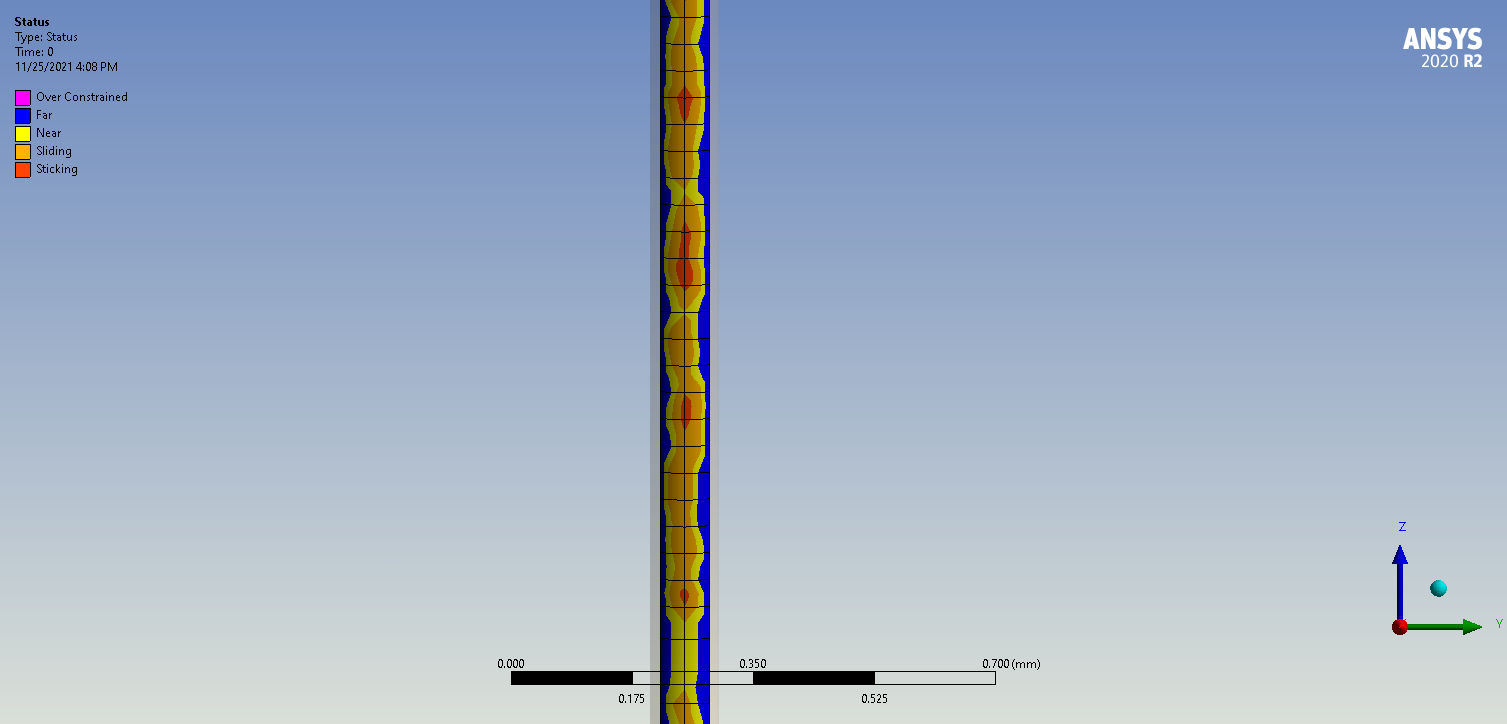

Furthermore, I am not very convinced of the initial state of the contacts:

Everything is very uneven and there are areas where the state is sticking.

Do you have any suggestions ?

Thanks in advance Fabry

November 26, 2021 at 2:42 pmAkshay Maniyar

Ansys Employee

It is good know that you were able to solve your convergence issue.

Can you try fine meshing on wire and the surface of contact. You can add contact sizing or manually do fine meshing. Because of fine meshing, it will increase number of elements in contact. Due to which, pressure distribution will also be proper.

Thanks amaniyar

Viewing 5 reply threads- The topic ‘CONVERGENCE PROBLEMS IN STATIC STRUCTURAL ANALYSIS WITH FRICTION CONTACT’ is closed to new replies.

Innovation SpaceTrending discussions- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Convergence error in modal analysis

- APDL, memory, solid

- Meaning of the error

- How to model a bimodular material in Mechanical

- Simulate a fan on the end of shaft

- Nonlinear load cases combinations

- Real Life Example of a non-symmetric eigenvalue problem

- How can the results of Pressures and Motions for all elements be obtained?

- Contact stiffness too big

Top Contributors-

4167

-

1487

-

1363

-

1194

-

1021

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.