TAGGED: membrane-elements

-

-

October 7, 2021 at 9:55 am

estat

SubscriberHi everyone,

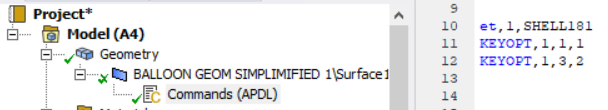

I am trying to simulate the deployment of cylinder using a Static Structural analysis of Ansys Workbench with a linear elastic material. I have no experince with shell elements so I am having trouble implimenting them. I found that Shell181 is a usefull membrane element when large deformations occur, since I also want to neglect the bending of the elements.

When applying radial pressure to the cylinder I get a Solver Pivot Error.

I attach below the way I applied the membrane elements and the error I get.

October 7, 2021 at 10:05 amErKo

Ansys EmployeeHi

Try to run it first without the membranes (so no snippet and

normal shells with bend. + membr. stiffness) and see if it runs. If it does not

then, you need to make sure that you have restrains, so for a sphere we could

use an eight of the model with symmetry and that should be well restrained to

take the pressure.

In general though, and if it does not run with the standard shell

(so no membrane formulation), then the below will help you:

First the snippet is (do not need the other 2)

keyopt,typeids(1),1,1

-

Typically, membranes do not have an out of plane stiffness so we

need that before we apply load to it.

So we need one step where we apply the inistate command (search

the apdl manual for inistate) for prestress on the membrane and then a second

step where we actually apply the pressure load.

Search for inistate and membrane and there will be lots of info on

this forum and on the web, e.g., :

­­

All the best

Erik

October 7, 2021 at 11:10 amestat

SubscriberDear Erik Thank you for your quick response.

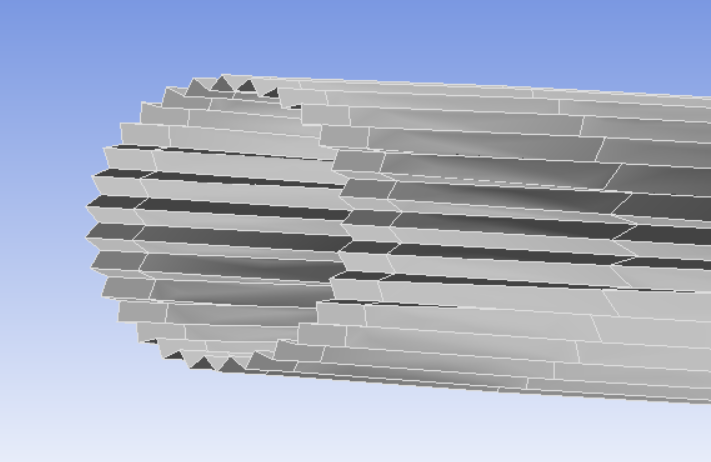

I attach the structure that I am dealing with.

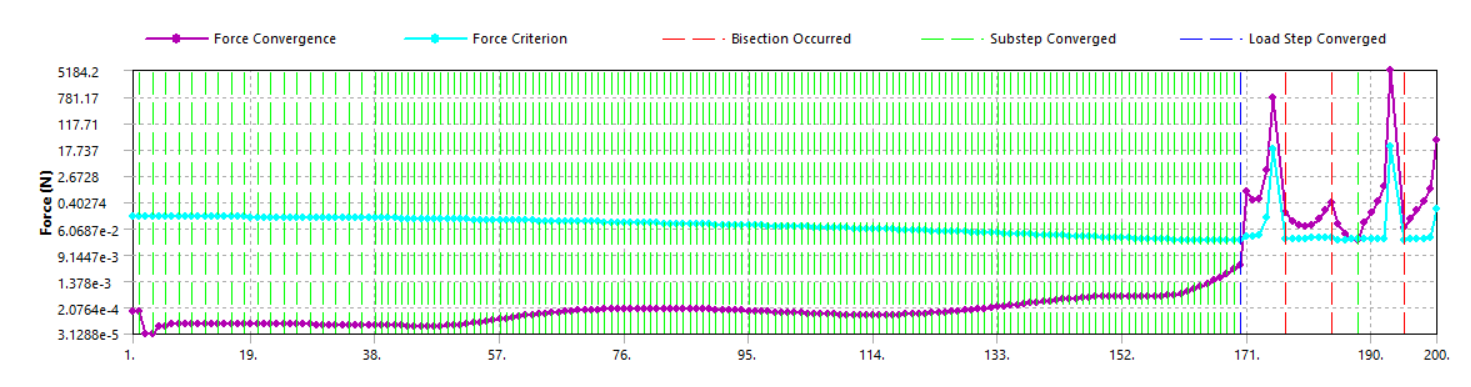

When trying the expansion with shell elements, the cylinder starts to expand until the point where it starts to stretch, where it fails to converge. I attach the failing point below. I only fix the sides and apply pressure.

When trying the expansion with shell elements, the cylinder starts to expand until the point where it starts to stretch, where it fails to converge. I attach the failing point below. I only fix the sides and apply pressure.

Thus, I considered this as a problem of the bending of the shell elements. What is your opinion on that? Should I go for shell or membrane elements?

October 7, 2021 at 11:20 amErKo

Ansys EmployeeHi

Is this analysis done with membrane so are you using the command snippet changing them to membranes, or is to done without a snippet and standard shell behaviour (bend.+membr.)?

All the best

Erik

October 7, 2021 at 11:24 amestat

SubscriberHi erik The one I posted is done with standard shell behavior.

Stathis

October 7, 2021 at 11:42 amErKo

Ansys EmployeeHi

If it works, I would say stick with it because membranes are very hard to get to work OK.

It looks like the folds want to straighten so that is going to be hard to do - try using stabilization (under and quasi static option (see below), and many substeps. These are all under analysis settings, and nonlinear controls (stabilization), and solver controls (Quasi-Static Solution -> Off or On) respectively.

If this does not work also, go to explicit LS-Dyna.

ALl the best

Erik

October 7, 2021 at 3:00 pmestat

SubscriberThank you for the reccomendations Eric!

I tried those but they do not seem to work. Could you please give me an explanation on why the shell elements have difficulties on simulating this expansion.

Would you suggest transient structural before using explicit solvers?

Thnak you for your time!

October 7, 2021 at 6:28 pmErKo

Ansys EmployeeNo worries.

It is a very challenging simulation since it involve extreme deformations and probably instabilities (wrinkling buckling of the fabric). Hence implicit solvers are not the most suited.

To be honest I think it is best to go to LS-Dyna that is used often for air bag inflation so it should cope with this (see here as an example)

Before that (going/switching to Ls-Dyna) you can try the semiimplicit command which basically switches also inside stati to an explicit when it does not converge :) - so again Explicit to the rescue :), and to aid convergence - k

Add a command snippet under the Static Structural tree branch and write:

semiimplicit

(see apdl help for more info)

All the best of luck

Erik

October 7, 2021 at 7:06 pmestat

SubscriberThank you Eric! You are really helpful!

I will try all of your recommendations. I guess the explicit solver can handle better the excessive elements distortion.

I will come back to report if the suggestions worked.

October 8, 2021 at 8:23 amErKo

Ansys EmployeeGood Morning

I think explicit should be able to solve without any issue - also LS-Dyna has some good material models (mat_fabric) for airbags and other inflatable structures. Nevertheless, seems that it might work to a certain extent, depending how far it needs to expand, the boundary load and material and structure type.

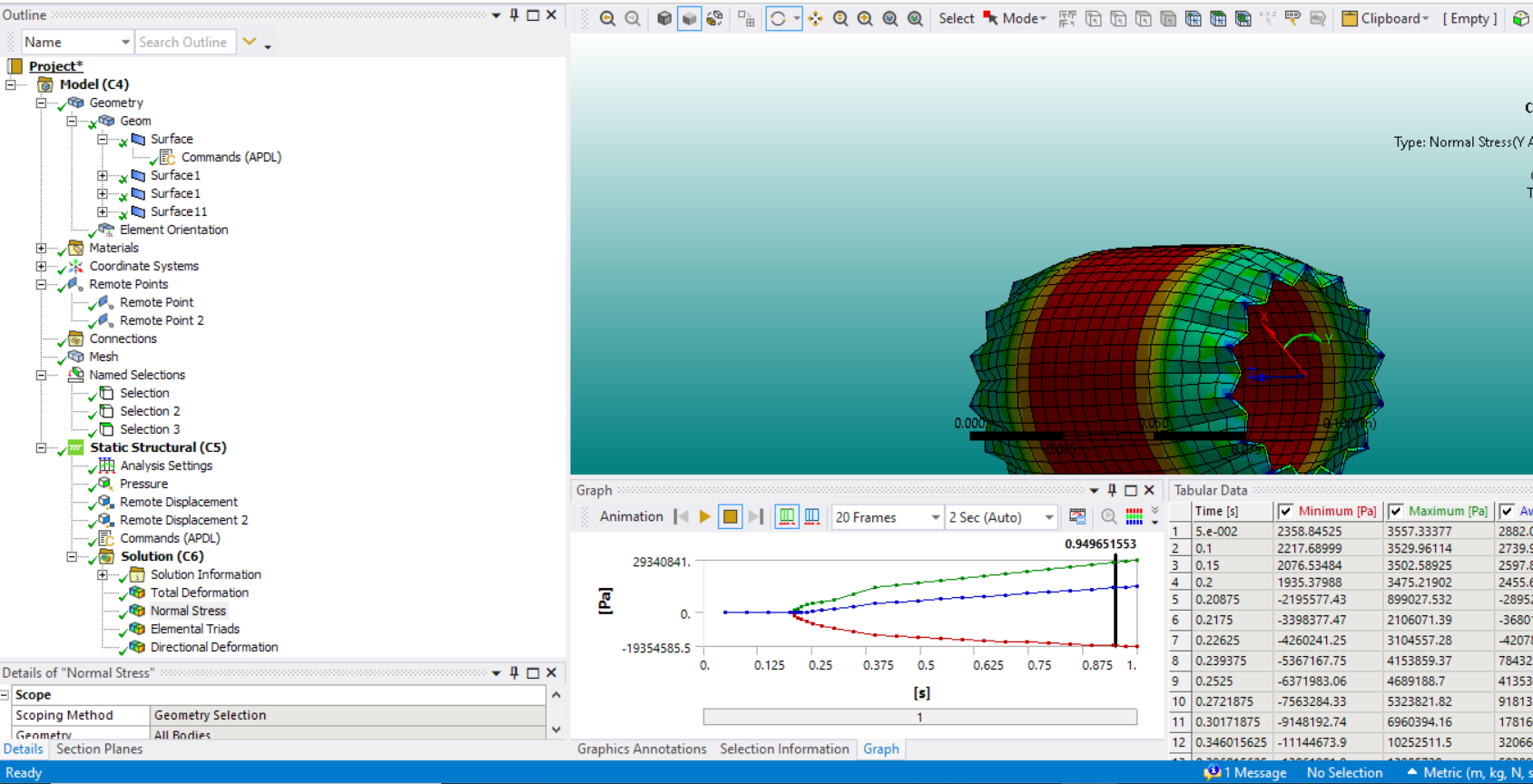

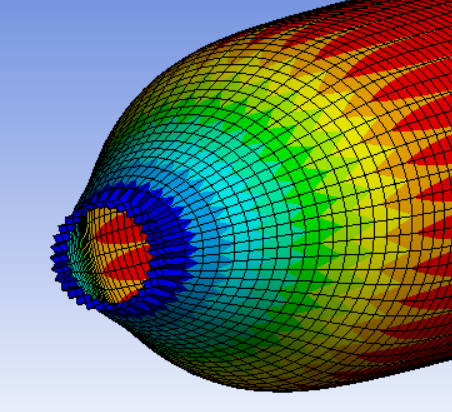

Made a quick test, and it might work with just a standard static and normal settings with membrane to inflate a thin fabric. The case below is for 1 mm thick, and E=500 MPa, v=0.4, that was taken up and above the theoretical material failure point (~ 20 MPa take just from the web, and research paper). The command snippet has the inistate prestress which is needed to get an initial stiffness on the membranes (keyopt,typeids(1),1,1), because without it they will not behave and converge.

Command shown below applying a small initial stress of 5000 Pa (small compared to 28 MPa it takes at the end as shown below) in the X and Y plate direction (to align the plate coordinate system we use an Element Orientation object (shown below) and align them according to the cylindrical coordinate system shown - that gives me consistent X-Y plate directions on the elements so we can apply the X Y pre stress):

inistate,defi,all,,,,5000,5000

So it should be perhaps possible (not using any stabilize or anything else) - of course depending how much we push it once expanded.

Perhaps if you post your model someone can have a look (unfortunately Ansys employee are not allowed to download attachments, but others can and they might be able to help).

All the best

October 8, 2021 at 1:20 pmestat

SubscriberHi Eric!

It is so nice of you to run the simulation yourself!

Thank you for all the recommendations!

Did you first try with shell elements or just with membrane elements? Will it work with shell elements also?

Can you share the commands (APDL) as a screenshot because I do not understand if instate and keyopt are the only commands you used?

Also can you show me the time step and end time that you used? Thank you!

October 8, 2021 at 1:51 pmErKo

Ansys EmployeeNo worries.

Only membrane since I think they are the most appropriate for fabric or membrane type of structure (textile,..).

Yes, these 2 were the only commands used. So the keyopt under the shell parts, and then inistate posted above, is under the static structural analysis just as shown in the image above.

The final time was 1 s, and 20 initial and min. steps and maximum 10000.

All the best

Erik

October 8, 2021 at 10:48 pmestat

SubscriberEric your recommendations on the static structural analysis with the membrane elements are working well!

However, the simulation converges with pressure rates 20 times lower than the ones it was ment to withstand.

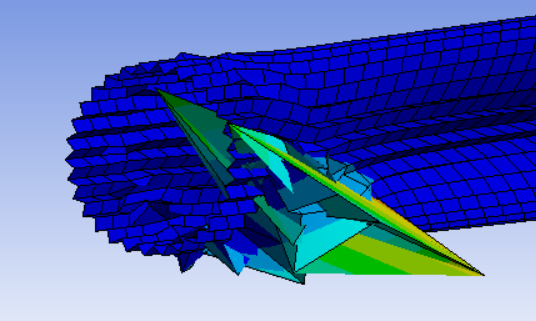

When I try to use just a slightly higher pressure rate, I get this error: Element 6963 has excessive thickness change.

When I try to use just a slightly higher pressure rate, I get this error: Element 6963 has excessive thickness change.

Any further suggestions ?

Any further suggestions ?

October 11, 2021 at 5:54 amErKo

Ansys Employee

Can you try to change initial sub steps to 200 minimum 100 and maximum to 10000.

October 11, 2021 at 7:18 amestat

SubscriberHi!

I already have set them at

Initial: 250

Minimum: 150

Maximum: 1000

I am implementing the pressure with a smoothstep function.

October 11, 2021 at 7:47 amOctober 11, 2021 at 8:27 amErKo

Ansys EmployeeHi

Try using semiimplicit apdl command in the second step see what happens (see help manual for that).

So entre a command snippet with that command and activate it only in step two (in the command snippet there is a step selection under settings)

(see here for details on step selection: https://www.padtinc.com/blog/running-an-apdl-command-snippet-for-every-load-step-in-ansys-mechanical/)

For ref., the semiimplicit method switches to an Explicit formulation if we do not get convergence).

All the best

Erik

October 11, 2021 at 10:32 amestat

SubscriberHi Eric!

I sincerely apologise. I misunderstood the pressure limit of my material.

Your recommendations on the membrane elements were correct. The linear elastic material that I used behaved properly until its failure point.

Now I want to try a hyperelastic material in order to get higher deformation but the simulation fails early with this warning.

Plane stress hyperelasticity did not converge for out of plane stretch.

Should I create a new topic about this because I know that this one has gone long long?

October 11, 2021 at 11:31 amErKo

Ansys Employee

Yes please , create new discussion since I am not an expert in hyperelastic material.

Thank you

Erik

October 11, 2021 at 12:12 pmestat

SubscriberYour help was truly valuable Eric!

Viewing 19 reply threads- The topic ‘Expansion of cylinder using membrane elements’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

5199

-

1859

-

1387

-

1250

-

1021

Top Rated Tags© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.