-

-

September 23, 2021 at 12:59 pm

cs_zy

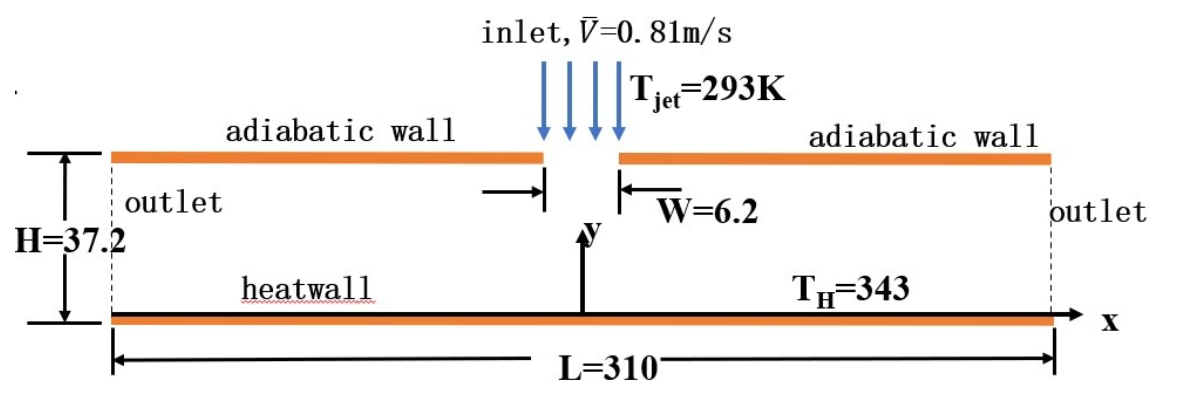

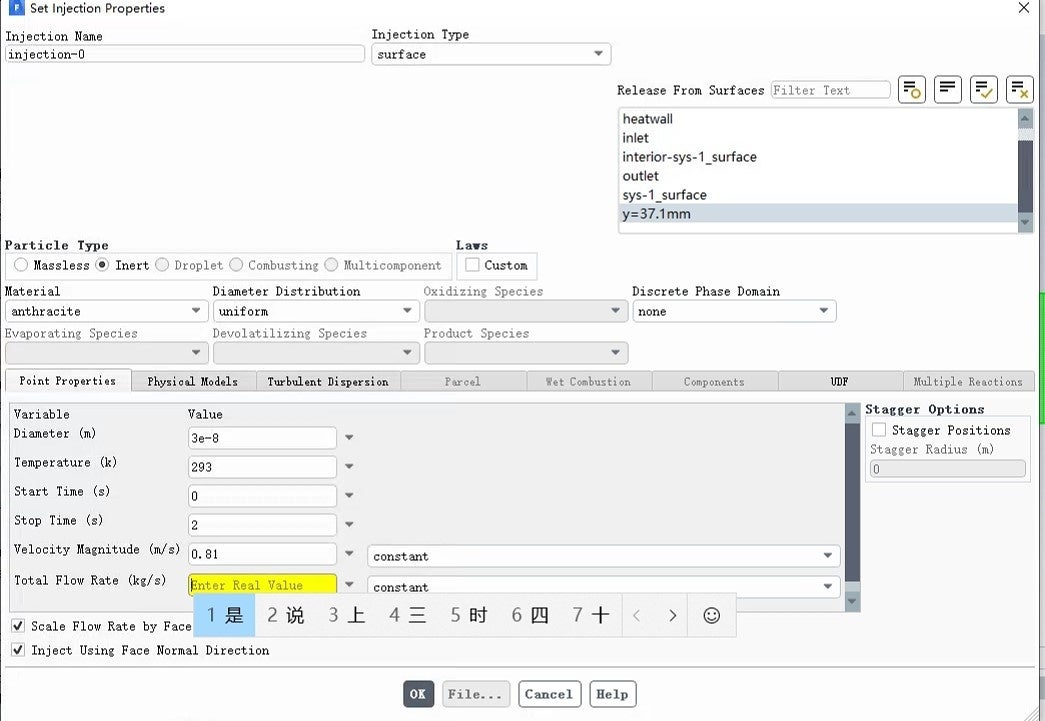

Subscriberwhen I use DPM model,how to compute Total flow rate ,when setting Point Properties for Surface Injections in 2D model?

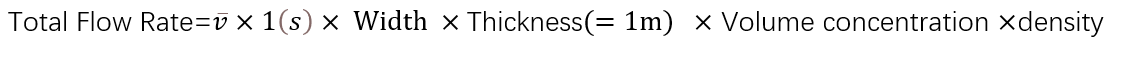

The Al2O3 volume concentration is 0.5vol% and density is 3970. The diameter of Al2O3 is 30 nm.Water idensity is 996.3.

And what any other parameters need I know?

Really appreciate if you could help me.

September 24, 2021 at 1:26 pmKarthik Remella

AdministratorHello Which flow rate are you interested in? The flow rate of the fluid or the rate at which the particles are being released? Or are you looking to estimate the number of particles?

Karthik

September 25, 2021 at 11:39 amSeptember 27, 2021 at 10:36 amRob

Forum ModeratorBy default Fluent assumes the 2d domain is 1m thick. At 30nm (ie tiny) the particles are pretty much doing to follow the flow.

September 27, 2021 at 2:16 pmSeptember 27, 2021 at 3:27 pmRob

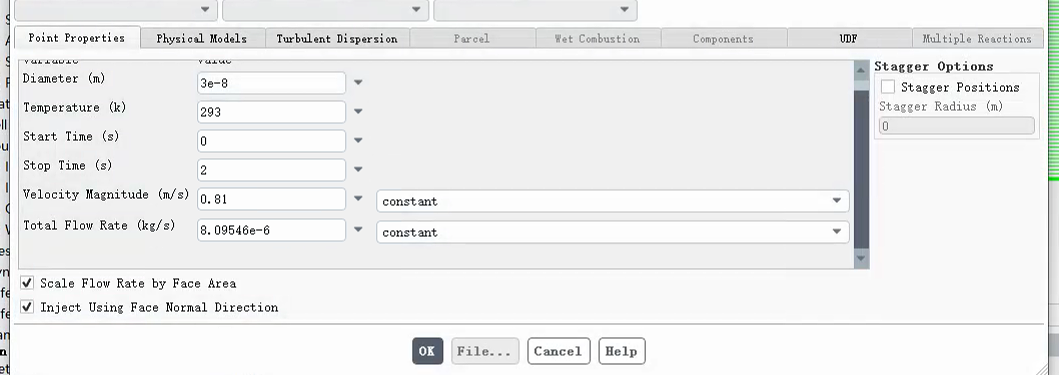

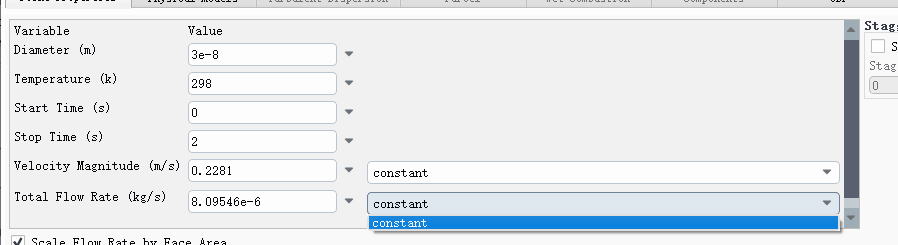

Forum ModeratorYou have a volume flow from the liquid: velocity*area. From that you can get the particle volume flow (5% of fluid), and then the mass using the particle density.

September 28, 2021 at 1:16 amcs_zy

SubscriberIs it mean value of time when the inlet velocity change with time? And My case is transient. Is the Total flow rate related to the integral time step of flow field or other parameters?

September 28, 2021 at 12:51 pmRob

Forum ModeratorThe total flow is how much mass per second you're adding through that injection.

September 28, 2021 at 1:34 pmcs_zy

SubscriberThank you!

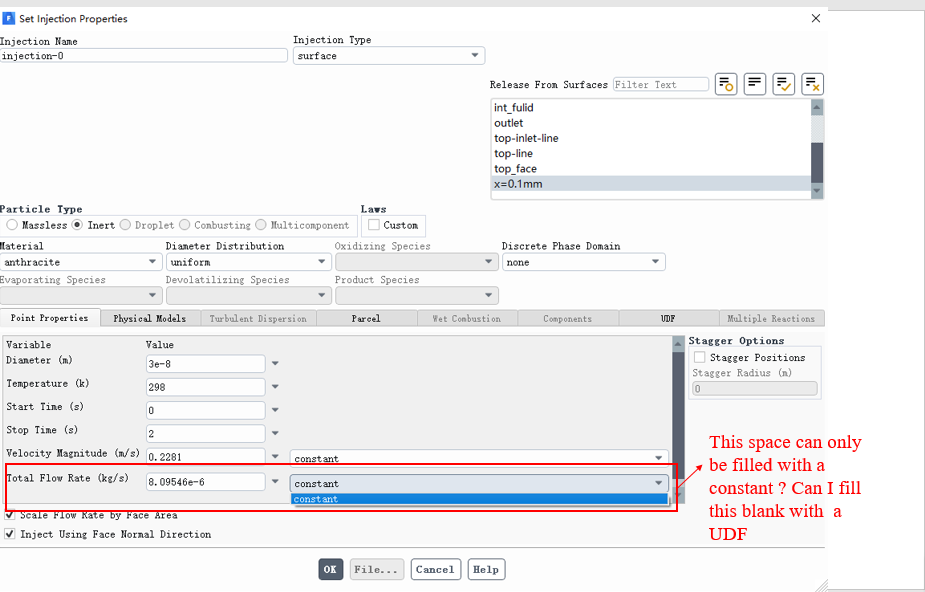

YesÒÇÇ´╝® know .I mean if my inlet velocity is changing with time and how should I compute? Using time average velocity instead of transient velocity?

September 28, 2021 at 2:59 pmRob

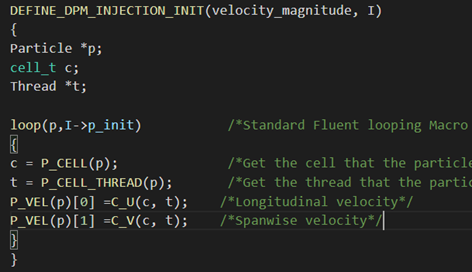

Forum ModeratorAh, time varying injection properties would need the DEFINE_DPM_INJECTION_INIT macro, which is covered in the manual. An easier approach would be to use multiple injections which turn on/off at certain times or ignore the transient part and use an average.

September 29, 2021 at 2:35 amSeptember 30, 2021 at 1:25 amSeptember 30, 2021 at 1:47 pmRob

Forum ModeratorI suspect it's PP_FLOW_RATE(p) from reading https://ansyshelp.ansys.com/account/Secured?returnurl=/Views/Secured/corp/v212/en/flu_udf/flu_udf_sec_define_dpm_injection_init.html Try it and see what happens.

October 1, 2021 at 2:26 amOctober 1, 2021 at 12:20 pmRob

Forum ModeratorRead how to hook up the DEFINE_DPM_INJECTION_INIT UDF. It's not the same as setting a boundary via DEFINE_PROFILE

October 13, 2021 at 1:58 pmOctober 13, 2021 at 4:04 pmViewing 16 reply threads- The topic ‘How to compute Total flow rate Surface Injections in 2 model?’ is closed to new replies.

Innovation SpaceTrending discussions- air flow in and out of computer case

- Varying Bond model parameters to mimic soil particle cohesion/stiction

- Eroded Mass due to Erosion of Soil Particles by Fluids

- I am doing a corona simulation. But particles are not spreading.

- Centrifugal Fan Analysis for Determination of Characteristic Curve

- Issue to compile a UDF in ANSYS Fluent

- Guidance needed for Conjugate Heat Transfer Analysis for a 3s3p Li-ion Battery

- JACOBI Convergence Issue in ANSYS AQWA

- affinity not set

- Resuming SAG Mill Simulation with New Particle Batch in Rocky

Top Contributors-

4167

-

1487

-

1363

-

1194

-

1021

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.