-

-

September 17, 2021 at 8:52 am

vishal295

SubscriberHallo,

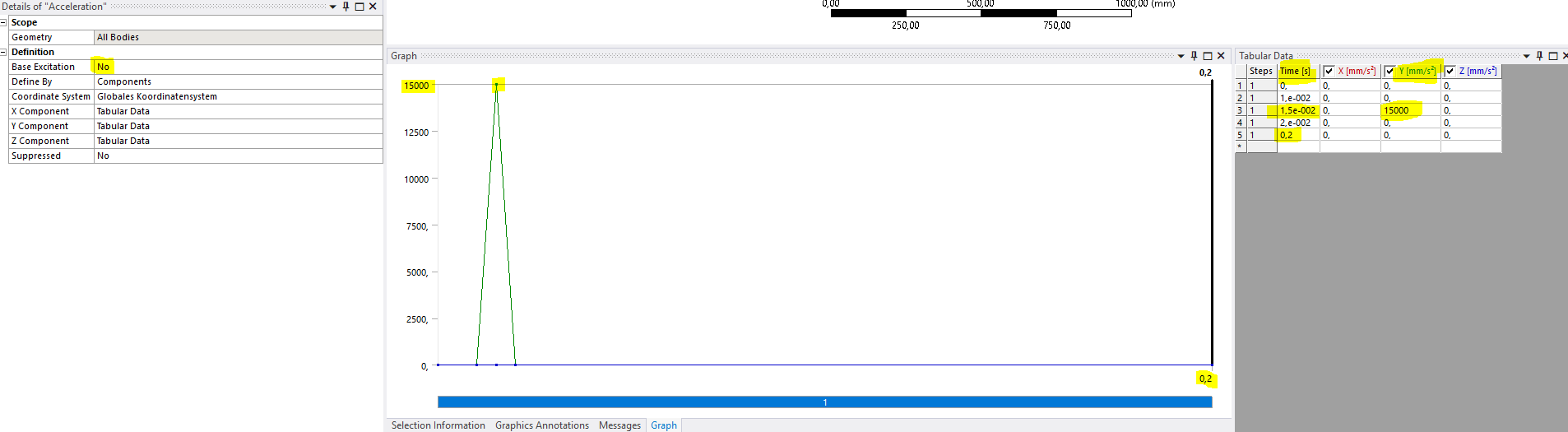

I am doing a vibration analysis and Shock / Transient analysis with 1.5 G acceleration for 30 milli-seconds time duration.

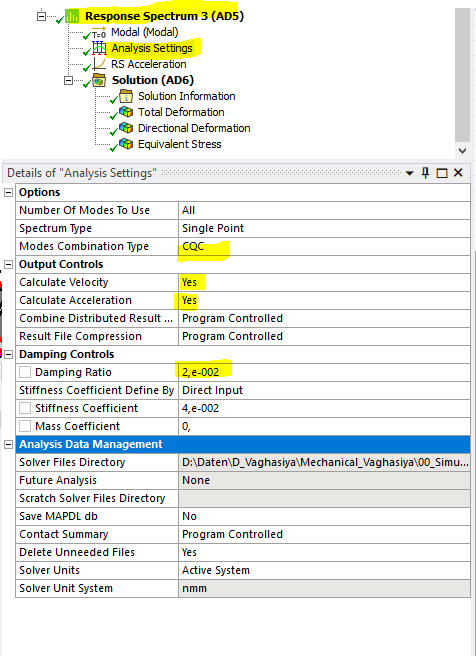

First of all I did Modal analysis and then response spectrum analysis (Linear) in Ansys Workbench Mechanical. Then did separate Non Linear Transient analysis. The acceleration boundary condition for each analysis is in the attached picture.

1) I am not sure if I applied acceleration Boundary conditions to Response spectrum analysis is true or not. Is it true ??? i.e. RS Acceleration 33,33 Hz to 15000 mm/S^2

2) If it is true then I am getting equivalent stress is very different for both ( for response spectrum it is in range of 6

September 17, 2021 at 9:36 pmpeteroznewman

Subscriber

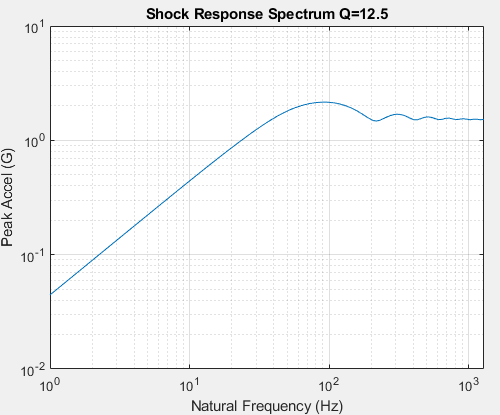

Your response spectrum is wrong. Do you have matlab? If so, there is a script that will compute the SRS from the acceleration time history in a package called vibrationdata.

You show you want a Damping Ratio of 0.04 so I converted that to a quality factor Q = 12.5

The SRS is a table with 125 rows of frequency from the plot shown above, but with acceleration converted to mm/s^2. That is in the text file attached. Copy and paste that data into the RS Acceleration load in the Response Spectrum analysis and the results from that analysis should come closer to the peak values from the transient analysis.

The SRS is a table with 125 rows of frequency from the plot shown above, but with acceleration converted to mm/s^2. That is in the text file attached. Copy and paste that data into the RS Acceleration load in the Response Spectrum analysis and the results from that analysis should come closer to the peak values from the transient analysis.

September 18, 2021 at 1:33 ampeteroznewman

Subscribersee my reply above.

September 18, 2021 at 3:59 ampeteroznewman

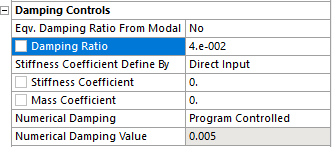

SubscriberAlso, in the Response Spectrum analysis, under Analysis Settings, do not add damping under Damping Controls because Damping of 0.04 was already specified as Q=12.5 when the SRS was computed. Where you have 2e-2 highlighted, set that to 0, otherwise you will be doubling up the damping.

Why did you request Damping of 2e-2 in the Response Spectrum but requested Damping of 4e-2 in Transient Structural? Was that just a mistake? Keep the Damping of 4e-2 in Transient, since that is what I used to build the SRS, but type in 90 Hz instead of 1 Hz because that is closer to the peak acceleration in the SRS.

September 20, 2021 at 11:33 amvishal295

SubscriberThank you for sending me that file.

I don't have Matlab. Even I didn't work with Matlab before. At the moment I am learning Matlab to convert the Acceleration time history to SRS data. Because I will need this to create SRS from different shock Acceleration just to check on my design.

So at the moment I should stick with Transient analysis results. And regarding damping 0.02 and 0.04 - Yes it was my mistake. Even I want to compare the response with both the damping values in Transient Analysis. And Thank you for suggestion regarding frequency value 90Hz for damping value.

So from Transient analysis I will check the weak point of the model and will check more about Fatigue tool in that.

Thank you Vishal

September 20, 2021 at 11:43 ampeteroznewman

Subscriber

So did the text file I provided make the output from Response Spectrum match the peak value from your Transient Structural analysis?

You don't need to know much matlab to use the vibrationdata package, it is a GUI where you just enter the data. You can download a zip file of all the scripts from the first link on this page:

https://vibrationdata.wordpress.com/2013/05/29/vibrationdata-matlab-signal-analysis-package/

After you extract the contents of the zip file into a folder, add that folder to the Path that matlab uses. Then simply type vibrationdata at the matlab command line. Once you have that, I can help you use it.

The reason to use Response Spectrum analysis instead of Transient Structural is to save time. I had a model that would have taken days of computation to solve in Transient Structural, but took only minutes of computation to solve in Response Spectrum.

Regards Peter

September 20, 2021 at 12:01 pmErKo

Ansys Employeeand

it is possible to create a shock response spectra in ansys mapdl:

see this post for mode details:

/forum/discussion/20382/how-to-create-a-shock-response-spectrum-from-time-history-data-with-apdl-commands

Hope this is of some help

Thank you

September 20, 2021 at 12:04 pmpeteroznewman

SubscriberThanks Erik

I try to avoid code as much as possibleSeptember 20, 2021 at 12:14 pmErKo

Ansys EmployeeNo worries - just thought to add it for completeness, and incase anyone would like to use it.

Erik

September 20, 2021 at 12:19 pmvishal295

Subscriber

Thanks again for sending me the vibrationdata link for matlab.

And Sorry I forgot to write about the file you sent for RS acceleration. Yes It worked and von Mises Stress value is now in the range of Stress result from Transient Analysis. YES, it is working fine.

You provided 125 rows data but for me there was warning that there are more than 100 rows. So there was limitation which I didn't understand, so I removed last 25 row data and worked with only 100 row data.

Yes I understood that Transient model analysis takes days to solve. In my case I have Fin wall transformer model which I had simplified to shell model and used distributed mass (for oil body) on the wall. And even for Non Linear analysis may I thought to use Transient Analysis. Initialy I took solid body for Oil in my model with E=0,01MPa (that I just used in other Modal analysis but not for random vibration analysis and other analysis). But with these I was time consuming.

Did my approach is right to use distributed mass on the wall of the transformer (for Fins of the transformer I used less distributed weight) ???

Thank you Erik for the link.

Even I trying to avoid code as much as possible.

Thank you Vishal

September 21, 2021 at 7:13 amvishal295

Subscriber

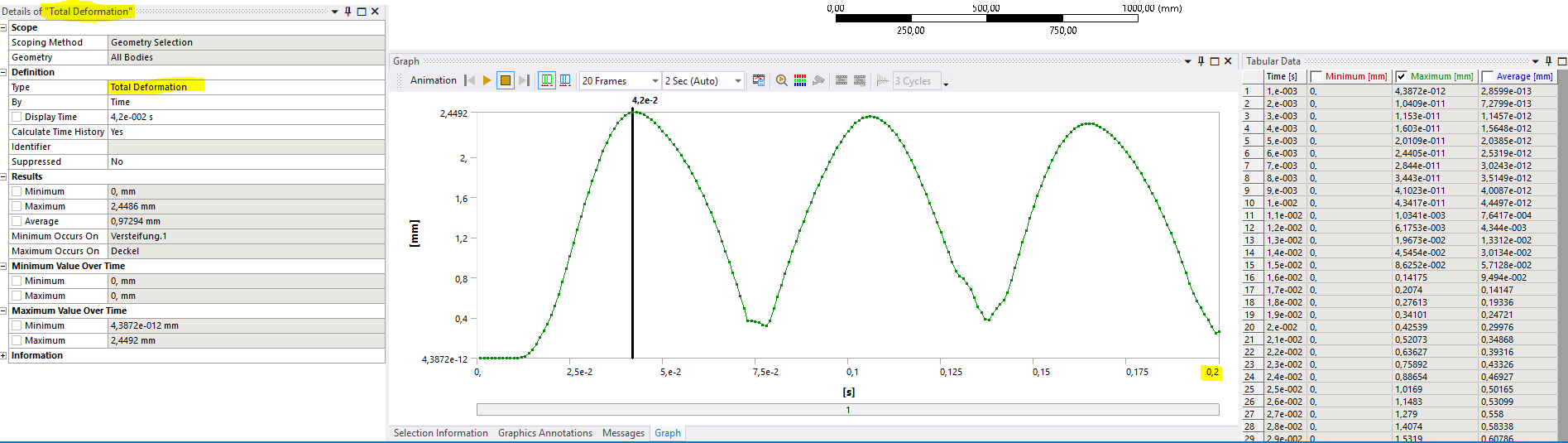

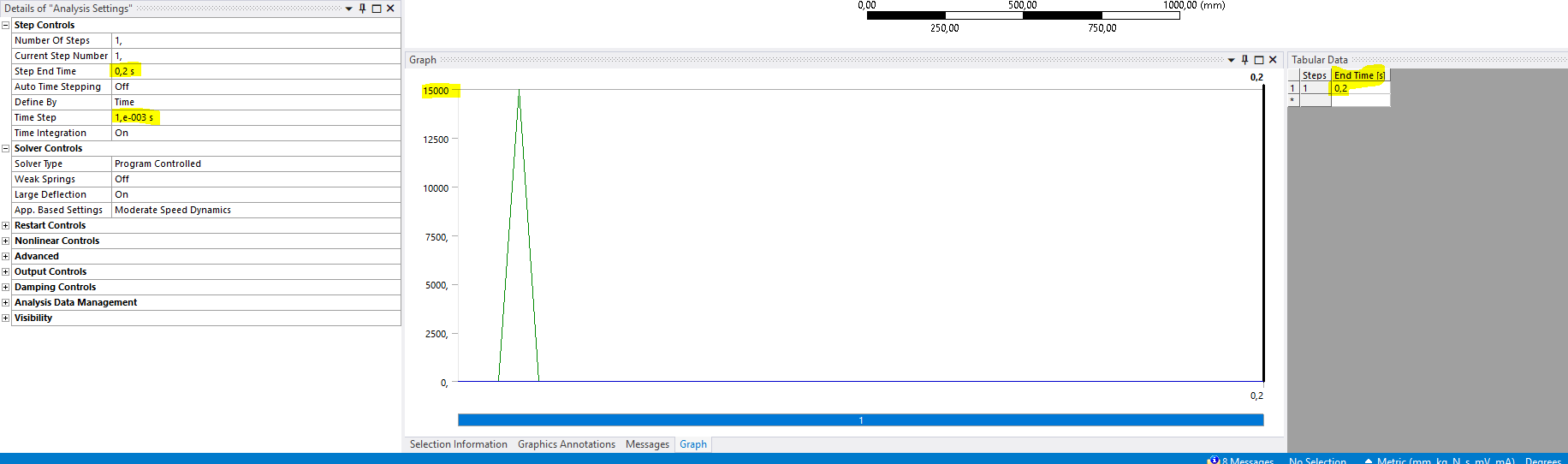

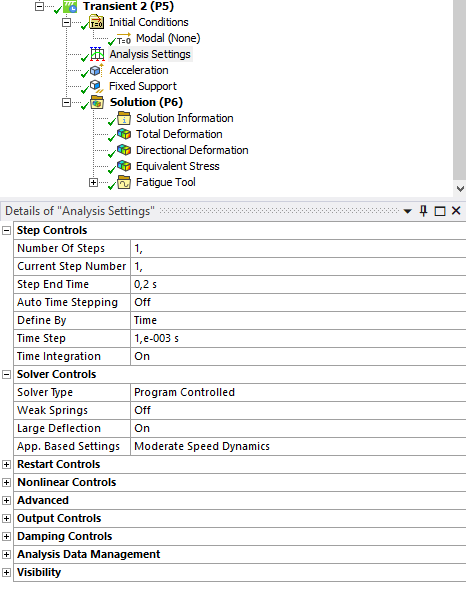

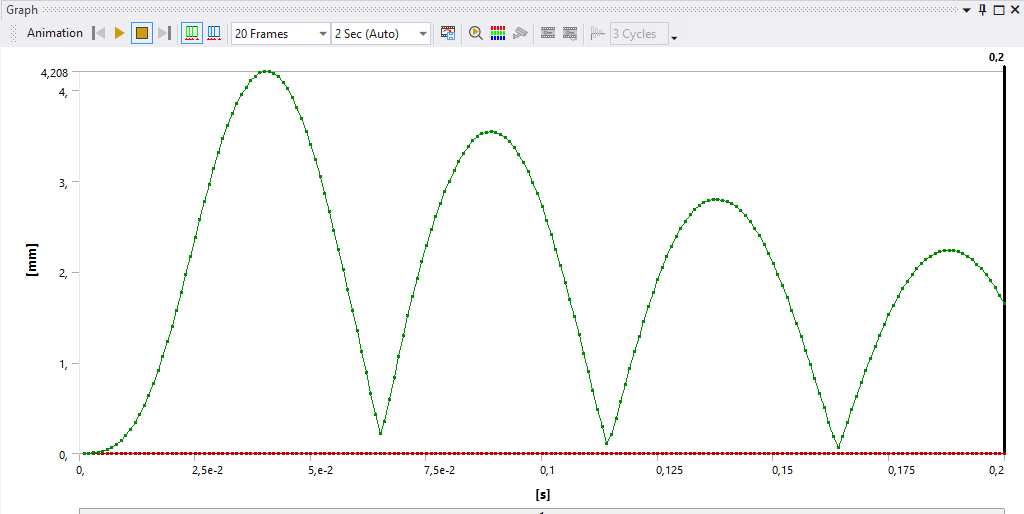

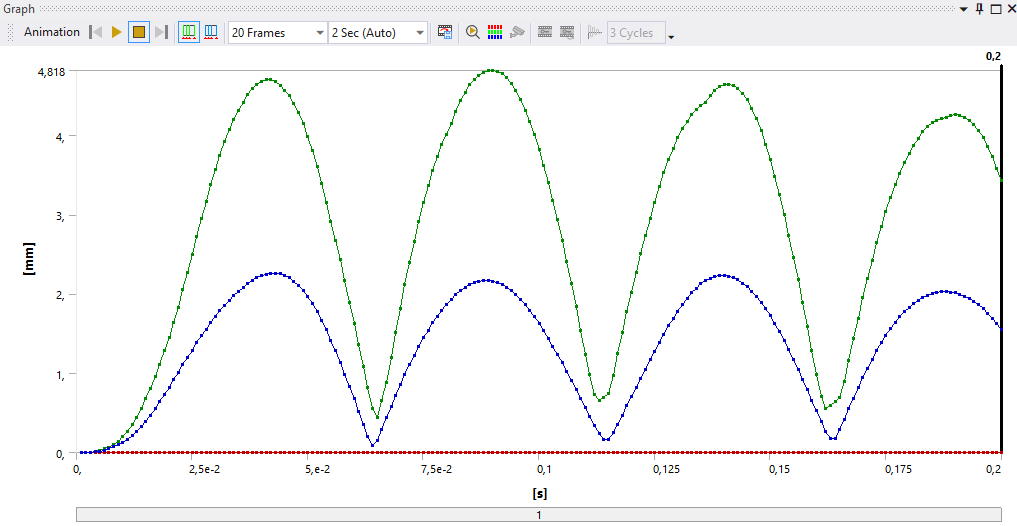

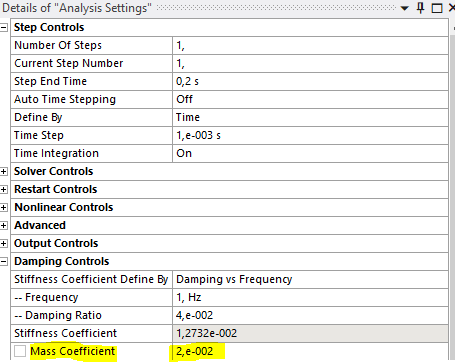

I did Transient Structural analysis in which I considered Analysis setting as below attached pictures (e.g. Time step and Acceleration etc.).

In Acceleration I applied 1,5 G Acceleration for 30 ms time period (means at 15 ms maximum acceleration peak of 15000 mm/s^2). And I applied Damping 4 % at 90 Hz Frequency vs damping.

And in result (in deformation) , I thought, Response of the structure might be near to zero or zero after 50 or 60 ms. to capture this I took end time step 0.2 second. But As can be seen from deformation result picture below, it is somewhat periodic and not going to zero.

In reality we can see that if we give shock to some structure for 30 ms and it gets absorbed or it dissipates after sometime or its deformation goes tends to zero.

Is my model setting is correct ? or am I missing something.

I kept Base Excitation = NO in setting.

Response spectrum stress result and Transient structural stress result also almost same in range of 120 MPa.

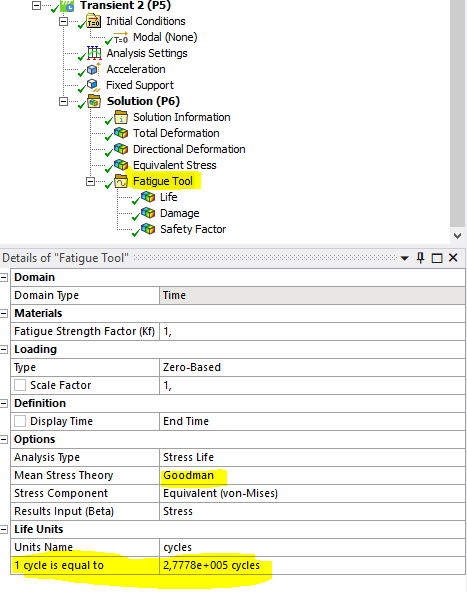

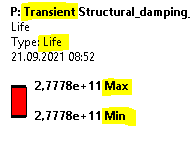

And in Fatigue tool I considered Goodman theory setting and Zero base Loading type to see the life time. And I expected different life time period for different parts in my model (I mean I have Transformer model and lower life time for fins near wall where stress is higher) but it is showing same life time for every component. Did I missed something or did wrong somewhere ?

Can you please help me with this ??

Thank you Vishal

September 21, 2021 at 12:02 pmvishal295

SubscriberFor Fatigue tool -Life or Damage, I don't have any data of Damage Evolution law or Damage initiation criteria for Engineering Material properties.

So I want to know how long the model can survive or number of Shocks or hours.

September 22, 2021 at 12:46 ampeteroznewman

SubscriberLook at the Modal analysis. Plot the First Mode and play the animation. Look at the point on the model that has the maximum deformation. Look at the direction that point is moving. Is it approximately moving along a Global Coordinate direction? If not, create a coordinate system that has an axis parallel to the path that the maximum point is moving. Plot Directional Deformation of that point and select the direction which aligns with the path that point move along in the First mode animation. Now you will have a plot that crosses zero and oscillates like a sine wave.

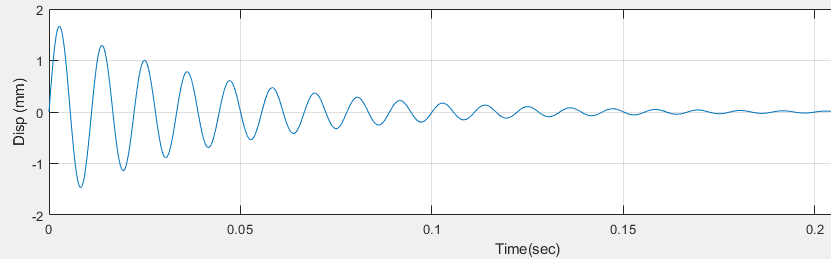

With 4% damping and a 90 Hz first mode, here is the displacement response of a mass-spring-damper system excited by a 100 cm/sec initial velocity.

If you don't get this kind of decay, there is something wrong with your model.

If you don't get this kind of decay, there is something wrong with your model.

September 22, 2021 at 7:54 amvishal295

SubscriberThank you .

My model's first natural frequency is around 7 Hz.

When I looked at the first mode and played animation, maximum deformation point was not parallel to Y axis (it was some what inclined around 5-6┬░ angle to the Y axis.)

Then I created several coordinate systems at that point and at different angles around 4,5,6,7 ┬░ angle. When I plotted directional deformation to these new coordinate systems, the response or graph of directional deformation was similar as global coordinate system's directional deformation graph and it is not decaying like the graph of mass-spring-damper system that you have attached above.

But when I was taking damping vs frequency for 1 Hz and 4 % damping, the directional deformation graph was decaying and went near to zero at 0.2 second.

Thank you Vishal

September 22, 2021 at 11:06 pmpeteroznewman

SubscriberSmall angles around the motion of the point don't make much difference. Even if the coordinate axis is the worst it can be, like 45 degrees, there is only a small reduction in peak amplitude.

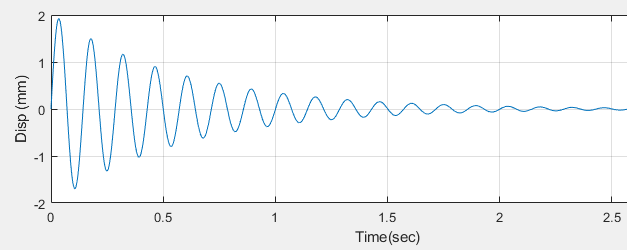

Mathematically, I can simulate a single DOF mass-spring-damper system with 4% damping and a 7 Hz natural frequency with a plot like this:

You can see that a 7 Hz natural frequency lasts longer than 0.2 seconds compared with a 90 Hz natural frequency. If your model decays much faster than this, then perhaps the model needs further adjustment.

You can see that a 7 Hz natural frequency lasts longer than 0.2 seconds compared with a 90 Hz natural frequency. If your model decays much faster than this, then perhaps the model needs further adjustment.

September 24, 2021 at 7:47 amvishal295

SubscriberThank you .

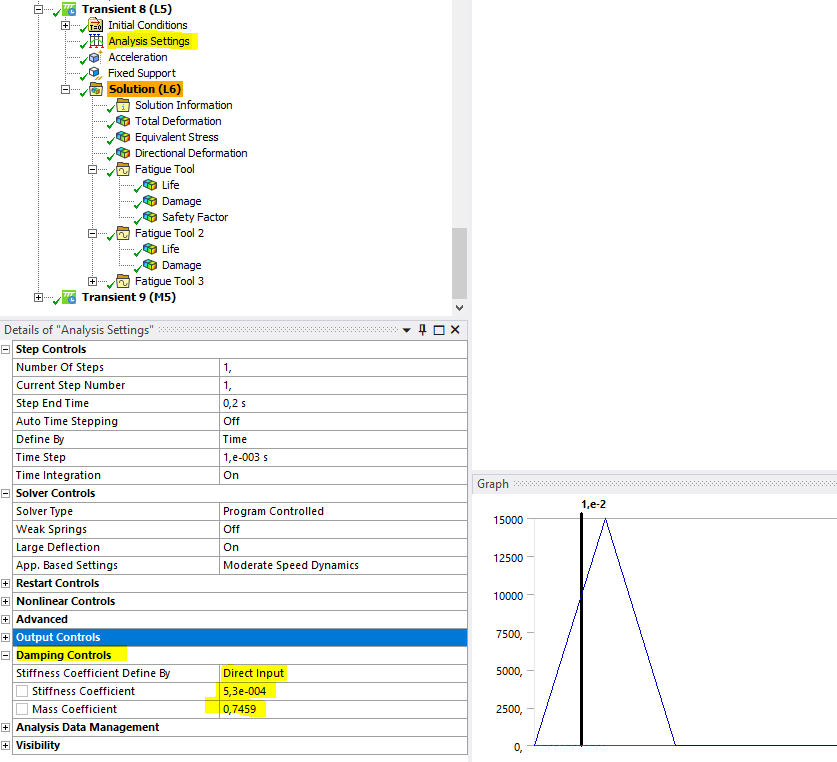

For my case 90 Hz frequency vs 0,04 damping lasts longer (2nd picture) than 7 Hz frequency vs 0,04 damping (first picture) decaying. These both can be seen in the attached pictures.

1 Hz frequency vs 0,04 damping - It is decaying much more quick near to zero as compared to higher frequency vs damping.

I don't know what kind of modifications I need to make to get such realistic phenomena. Can anyone please suggest me regarding this ???

info : For Fatigue tool in Random vibration - I have opened separate discussion for this. Because I did not want to mix Random vibration and Transient structural. (Fatigue Tool in Random Vibration ÔÇö Ansys Learning Forum)

Thank you !

Vishal

September 24, 2021 at 12:42 pmpeteroznewman

SubscriberPlot Directional Deformation of a point, do not plot Total Deformation.

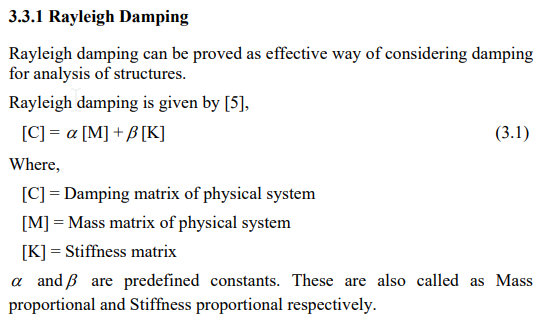

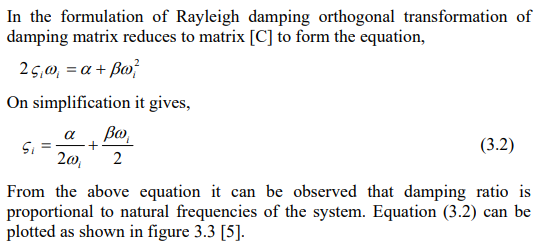

The frequency of oscillation I see in the plot is closer to 10 Hz than 7 Hz, but that is not so important. What you need to understand is the difference between Rayleigh Damping constants alpha and beta and the Damping Ratio constant zeta. This paper: http://www.diva-portal.org/smash/get/diva2:832236/FULLTEXT01.pdf has on page 10:

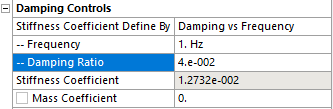

When you have a Full Transient (not MSUP), you are entering alpha and beta. ANSYS includes an equation to convert a Damping Ratio and Frequency into a value of alpha.

When you have a Full Transient (not MSUP), you are entering alpha and beta. ANSYS includes an equation to convert a Damping Ratio and Frequency into a value of alpha.

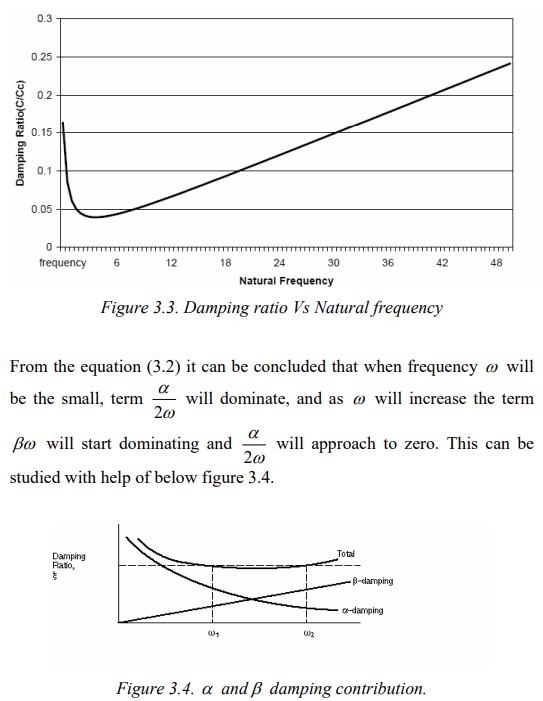

But look, it only calculated beta, the Stiffness Coefficient and left the mass coefficient at zero, which means that the damping ratio is linearly increasing with frequency.

But look, it only calculated beta, the Stiffness Coefficient and left the mass coefficient at zero, which means that the damping ratio is linearly increasing with frequency.

You should select two frequencies where you want a relatively flat value of Damping Ratio and compute both alpha and beta to achieve that as shown in Figure 3.4.

When you have a MSUP Transient, you can either enter alpha and beta OR you can have a constant value of Damping Ratio.

When I use matlab to compute the transient response of a single DOF mass-spring-damper system, the Damping Ratio is constant.

When I use matlab to compute the transient response of a single DOF mass-spring-damper system, the Damping Ratio is constant.

Finally, plot Directional Deformation of a point, do not plot Total Deformation.

September 27, 2021 at 11:42 amvishal295

Subscriber

Thank you Peter for detailed suggestion regarding damping. Yes I had a looked at this whole Thesis (paper) regarding Rayleigh damping.

If I understood right that I will need two damping value at different 2 frequencies. But I couldn't find any option to enter damping value for another natural frequency. Is it possible to enter 2 damping value for 2 Frequency together ??? If yes then can you please let me know how I can do this thing ?? (for FULL Transient)

Because when I tried to give some random value to ''Mass Coefficient value'' (attached in picture). But It didn't make any difference in result. (Yes I understood that I need to provide value for another frequency value also) But I don't know how.

Thank you and Best regards

Vishal

Thank you and Best regards

Vishal

September 27, 2021 at 12:07 pmpeteroznewman

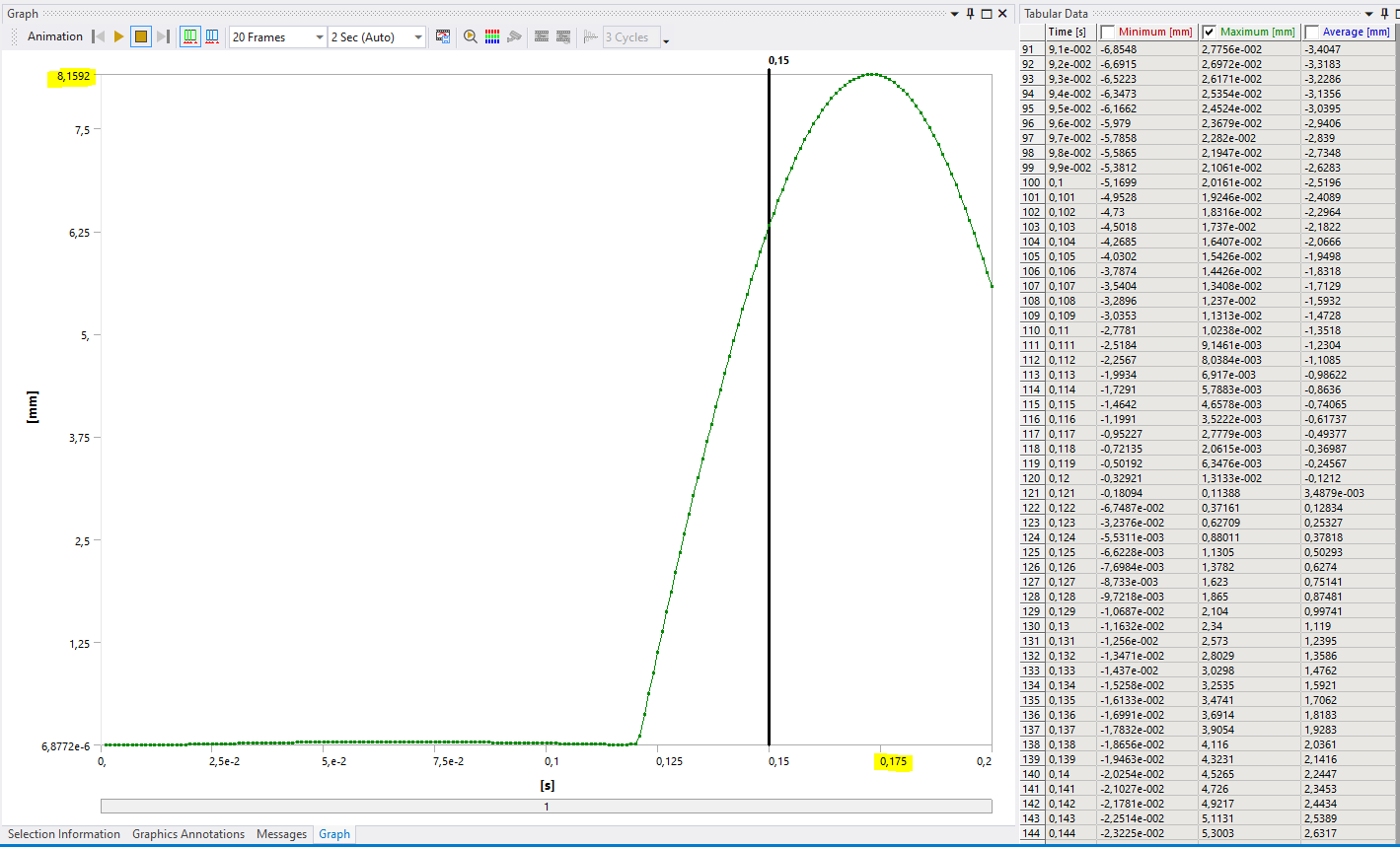

SubscriberFirst pick your two frequencies and use your desired damping ratio of 0.04 then solve the two equations to obtain alpha and beta.

Then change the Damping Controls and define Stiffness Coefficients not by Damping vs Frequency, but Direct so you can enter the alpha and beta you calculated above.

September 28, 2021 at 12:13 pmvishal295

SubscriberHi peter

Thank you for the reply.

As you suggested, I considered two damping values (2% damping at 5,35 Hz (first natural frequency) and 5% damping at 28 Hz (10th natural frequency)) and from this I calculated alpha and beta coefficient (which i applied directly in Direct Input as in attached picture) from the equation from the Thesis (regarding Rayleigh damping) for my model and applied as in attached picture and the resultant directional deformation as attached in picture. But Result (deformation) is similar to Frequency vs damping (90Hz and 4% damping).

May I will play with other damping value for different frequencies for better comparison.

Meanwhile if you have any further suggestion for my model then please let me know.

Thank you and best regards Vishal

Viewing 19 reply threads- The topic ‘Transient Analysis and Response Spectrum – Structural’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

4673

-

1565

-

1386

-

1236

-

1021

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.