TAGGED: fluent, multiphase, no-separation

-

-

September 6, 2021 at 2:19 pm

Hakim

SubscriberHi ,

Good day,

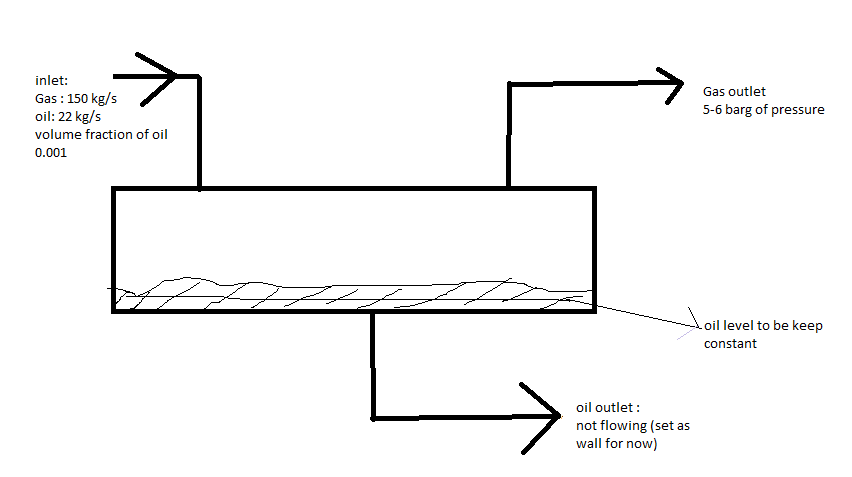

I'm trying to simulate the separation of gas and oil in the separator vessel. At the inlet of the vessel, we assume that the fluid (oil and gas ) is in well-mixed condition(with an oil volume fraction of 0.001). It has 2 outlets, gas at the top of the vessel and oil at the bottom. Currently, results generated showing that all the oil is carried over to the top of the vessel (out at the gas outlet). It doesn't show the separation process due to the density difference.

The current setup are:

Multiphase VOF: implicit body force, Constant surface tension

Turbulence; K-epsilon realizable with standard wall function

Adapt region:1/3 of the vessel is Patch with oil to simulate the oil level in the vessel.

Boundary condition :

Inlet- inlet mass flowrate

Outlet: Pressure outlet for gas outlet, outlet mass flowrate for liquid at the bottom :

Material: for gas -Ideal gas law,

Constant density for liquid.

Gravity- enable

Solution: Steady-state.

September 6, 2021 at 4:18 pmRob

Forum ModeratorWith a volume fraction of 0.001 and fully mixed the VOF model is not what I'd be using. Ideal gas is questionable too. Sketch out the device and add pressure & flow rates to the sketch along with the expected free surface level.

September 6, 2021 at 5:11 pmAmine Ben Hadj Ali

Ansys EmployeeSeparation: Eulerian or DPM or Mixture with custom slip. First start with what Rob suggested.

September 6, 2021 at 5:25 pmSeptember 7, 2021 at 9:44 amRob

Forum ModeratorOK, that looks very much like a knock out drum, so whilst it's a separator we may not need as much complicated physics. We designed these in 1st year project week when I was a student, and as I used it as an example in an old marketing event I can even go through the process; no bacon butties this time though :( .

Gas pressure won't drop much so you can alter the material properties and use fixed values. Density will be in the order of 8kg/m3, not sure about viscosity. Velocity will be low as you want droplets to settle & that takes time. Free surface can be assumed to be fixed, ie draw the vessel as per CAD and remove the bit that's under the oil. Any droplets that hit the oil are assumed to separate, anything hitting the vessel walls probably does. Look up the knock out drums as I think you're missing the demister.

September 7, 2021 at 2:21 pmHakim

SubscriberHi Rob Yes, it is a KO drum.

What physical model should I use, is it DPM model is enough?

Appreciate your advice.

September 7, 2021 at 4:09 pmRob

Forum ModeratorDPM is fine - it's a dispersed particle (droplet) stream. I'd also look at the wall film models if you want to extend the model a bit: it's not necessary but is something to look at as a second step if you have time.

Viewing 6 reply threads- The topic ‘Multiphase Separation issue’ is closed to new replies.

Ansys Innovation SpaceTrending discussions- air flow in and out of computer case

- Varying Bond model parameters to mimic soil particle cohesion/stiction

- Eroded Mass due to Erosion of Soil Particles by Fluids

- I am doing a corona simulation. But particles are not spreading.

- Guidance needed for Conjugate Heat Transfer Analysis for a 3s3p Li-ion Battery

- Centrifugal Fan Analysis for Determination of Characteristic Curve

- Issue to compile a UDF in ANSYS Fluent

- JACOBI Convergence Issue in ANSYS AQWA

- affinity not set

- Resuming SAG Mill Simulation with New Particle Batch in Rocky

Top Contributors-

3882

-

1414

-

1241

-

1118

-

1015

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-