-

-

August 11, 2021 at 5:02 pm

AaronW

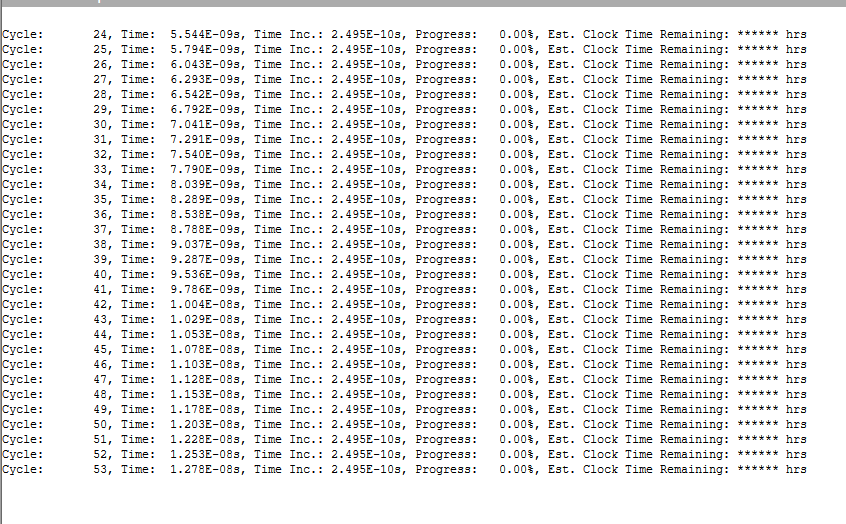

SubscriberWhenever I solve my explicit dynamics simulation, I keep getting in the solution a time that looks like the image attached below, or somewhere in the region of 4500-4800 hours. I know I must have made some error in the at some point, whether it is in the analysis setting or elsewhere in the project. Has anyone experienced this before and does anyone have any idea how to fix this? I doubt a 128,000 element impact sim is meant to take half a year to render.

Cheers lads

August 11, 2021 at 5:31 pmagopalkr

SubscriberI had a similar problem, my model was made in design modeler in the units of microns. I forgot to change the units in mechanical to microns, I set the boundary conditions and realized it was in meters and then changed it to microns. However, the simulation run time was days.

To workaround this, I reset mechanical and selected the units to microns from the get go and the run time was in minutes.

Not sure if this applies to you, but might be worth checking out if you made/imported your model in design modeler.

August 11, 2021 at 6:06 pmAaronW

SubscriberNah mate, designed it and made it in SpaceClaim.

August 11, 2021 at 6:20 pmpeteroznewman

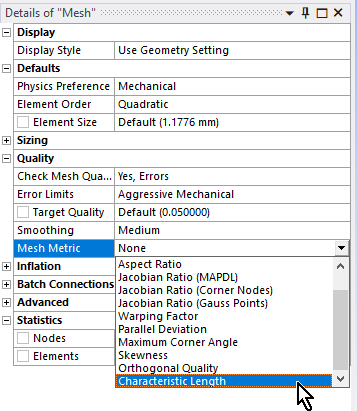

SubscriberLook at the Time Step, it is 2.5E-10 seconds. The time step is automatically calculated from the shortest characteristic edge length in the mesh. Open your model and on the Mesh branch, in the Details window, set the Mesh Metric to Characteristic Length (it's last on the list). What is the minimum value in the summary? That is the element that is setting the time step. If you can remesh and make the minimum characteristic length 100 times larger then the time step will be 100 times larger and the solution time will be 100 time shorter.

Check that you put the correct value for the units in the material density. Maybe you didn't notice that the units were set wrong. If the density is 100 times too light, the simulation will take 10 times longer because the time step is a function of density.

Check that you put the correct value for the units in the material Young's Modulus because the time step is a function of Modulus.

August 11, 2021 at 6:31 pmAaronW

SubscriberThank you very much mate! I'll be sure to try it!

August 11, 2021 at 8:00 pmAaronW

SubscriberI cant change the values of the mesh in mesh metric, how exactly do I do it?

August 11, 2021 at 8:47 pmpeteroznewman

SubscriberAugust 11, 2021 at 9:01 pmAugust 11, 2021 at 10:45 pmpeteroznewman

SubscriberI went to a concert at a small venue a few years ago with my Scottish friend to listen to The Proclaimers. Half the audience was ex-pat Scots and everyone had a great time!

Are there any elements in the simulation that have no density or mass assigned? Solid elements with a material with a density will not give a zero characteristic length. Do a save as to a new name and see what happens if you delete everything except for the solid elements.

August 11, 2021 at 11:12 pmAugust 12, 2021 at 12:41 ampeteroznewman

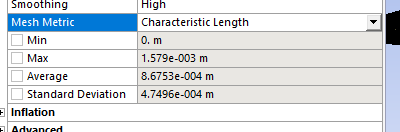

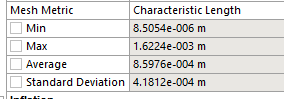

SubscriberYou can see that the average element Characteristic Length is 8.5 e -4 while the minimum Characteristic length is 100 times smaller.

Use the Mesh Metric display to find the elements where the characteristic length is near the minimum. It may be possible to edit geometry and use mesh controls to increase the characteristic length by a factor of 100 then the 850 hours will become 8.5 hours.

August 12, 2021 at 3:42 pmAaronW

SubscriberI have managed to get it down significantly, but when I then solve it, the time just goes up and up and up! Begins at around 12-20 hours and just goes up more and more! I really do not know what to do anymore

August 13, 2021 at 12:20 pmpeteroznewman

SubscriberSolution time goes up when elements change shape and the characteristic length goes down. Plot equivalent strain to find the location in the model where the highest element distortions have occurred.

The solver has a feature called Erosion, which removes elements that are highly distorted or have exceeded the material failure limit. Under Analysis Settings, Erosion Controls, you will find the default settings are to remove elements whose strain is larger than 1.5 (150%). There is also a setting to remove elements on Material Failure, assuming the material has failure defined.

Are you using a material from the Explicit Dynamics library, such as one that has an EOS material definition? Have you changed the default erosion controls? Try using a material from the library and change the setting to remove on Material Failure.

August 14, 2021 at 4:11 pmAaronW

SubscriberLowering the geometric strain limit seems to help a lot, thanks. What ideally should I put it at? I have it at 0.3 currently, but there is no reasoning behind that.

August 14, 2021 at 9:22 pmpeteroznewman

SubscriberDuctile materials such as metals like steel and aluminum have a tensile strain limit called Elongation at Break, which is a material property. It is the Engineering Strain when the tensile sample broke into two pieces. Look up Elongation for your material.

Viewing 14 reply threads- The topic ‘Keep getting impossibly long/ infinite (?) solve times. HELP NEEDED!’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

5154

-

1836

-

1387

-

1248

-

1021

Top Rated Tags© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.