Overview:

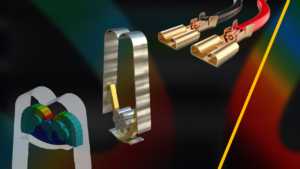

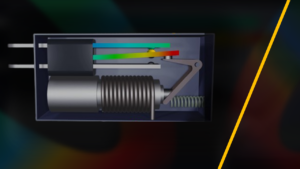

The electric vehicle (EV) market is growing exponentially, presenting several functional challenges towards achieving an optimal battery design. It is critical that batteries be designed to operate successfully and at peak performance in all situations. The increasing maturity of simulation processes to replicate physical lab tests accurately enables fewer physical prototypes and accelerated time to market. These benefits of simulation come with challenges of their own unless engineers use proven and validated methods when constructing simulation models. The tools themselves are not sufficient to ensure successful simulation models. Equally important is how to apply the tools in an effective and proven manner. This premium learning material will enable engineers, designers, and analysts to develop a structural finite element model of a typical battery suitable for performing structural integrity simulations.

Learning Outcome:

Following completion of this premium learning material, you will be able to:

- Develop a structural finite element model of a typical Li-Ion battery suitable for performing structural integrity simulations, including Vibration/NVH, Crush/Impact, Drop and Durability

- Use proven, best-practice approaches for importing and managing source CAD file data for these large assembly models

- Perform assembly simplification and geometry clean-up that will result in a finite element mesh that will ensure solution efficiency while retaining major geometry features of the battery

- Represent the full material characteristics of the battery assembly

- Use proven Ansys contact modeling technology to accurately represent interaction among assembly components within the battery

Prerequisites:

- A basic knowledge of using Ansys Discovery

- A working understanding of using Ansys Mechanical.

Estimated Time: 7 Hours.

You are being redirected to our E-commerce site to provide you an optimal buying experience experience. Please refer to our FAQ page for more details. Click this link to proceed.