Ansys Rocky Blogs & Articles

In this page you can find the latest article and blog content from the Ansys Rocky team.

Ansys Rocky FAQs

Find here posts with frequently asked questions (FAQs) from our Rocky customers with answers from our team of experts and other engineering simulation contents.

5 great Rocky Modules to improve your simulations

Whether you are new to Rocky or looking to optimize your current workflow, this article brings 5 of these modules to improve your simulations and key information to help you choose and apply the right tools for your project goals.

How to debug your own Ansys Rocky Custom Modules -- [Solver SDK]

In this article, we will walk through a step-by-step approach to debugging your own custom modules -- from setting up your development environment to interpreting log messages and using external tools like Visual Studio for deeper inspection.

Ansys Rocky + Ansys EnSight: Leveraging Simulation Postprocessing to new levels

Post processing is an important part of a simulation project. It is the moment you can finally see how your knowledge and the tools that you had in your hand reproduced the real world on a screen. When combined these two software bring to your simulations deeper insights into complex systems and maximize the visualization capabilities.

Mastering Multi-GPU in Ansys Rocky Software and Enhancing Its Performance

Innovative algorithms for DEM methods and the computational power from graphics processing units (GPUs) have opened new horizons.With Ansys Rocky particle dynamics simulation software, these loads can be offset by using GPUs, which provide the capacity to obtain results in a more practical time frame.

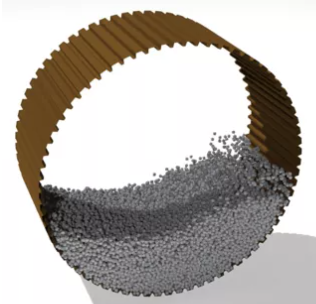

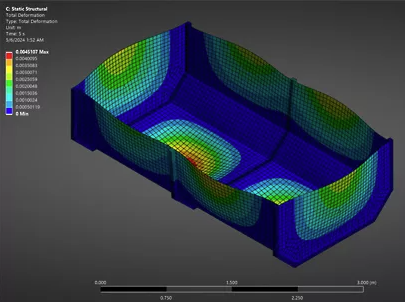

Maximizing Simulation Capabilities by Coupling Structural and Particle Software

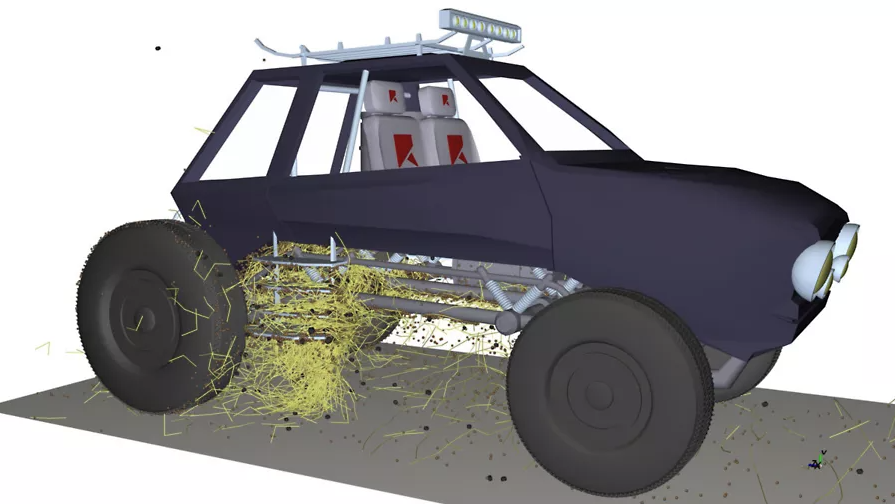

In industries such as mining and materials processing, many operations involve mixes of particles interacting with solid systems. To improve efficiency and drive big-picture insights, engineers must be able to understand this complex interaction from every angle. Combining the powers of structural and particle simulation enables you to gain a greater understanding of these processes while also reducing costs and saving time.

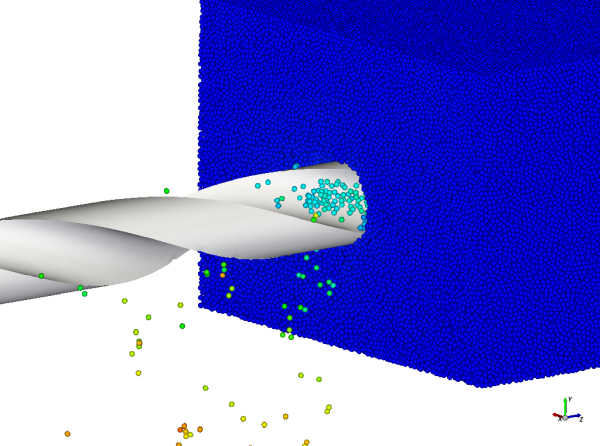

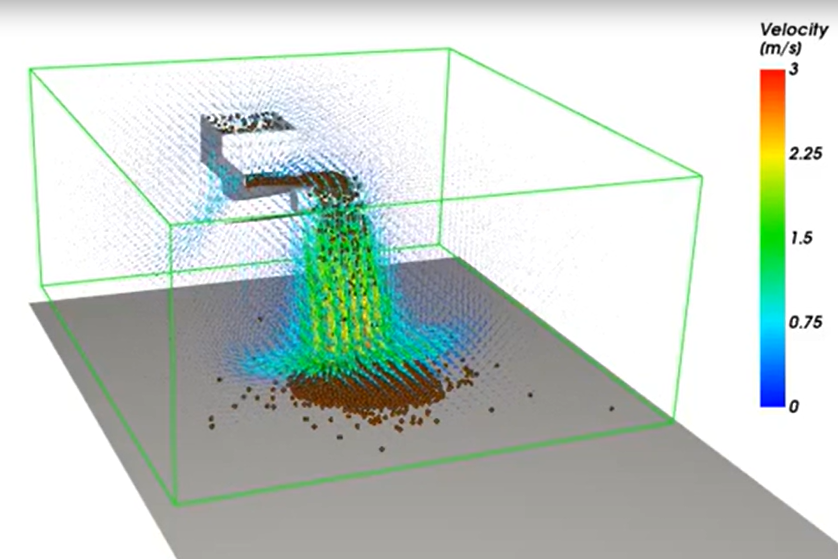

Unlocking the Power of CFD-DEM Coupling: Modeling Fluid-particulate Systems

Coupling computational fluid dynamics (CFD) and the discrete element method (DEM) expands the range of granular-fluid systems that can be addressed through numerical simulations. Learn how CFD-DEM coupling works, the types of coupling available in Ansys Rocky, and how you can unlock the power of CFD-DEM by coupling Ansys Fluent and Rocky.

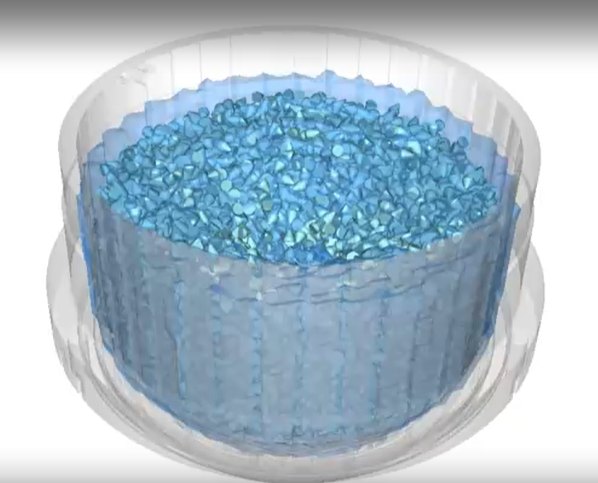

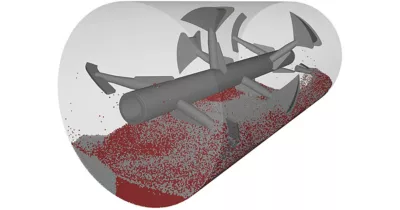

Smoothed-particle Hydrodynamics and DEM: A Powerful Solution to Simulate Solid-fluid Applications

Rocky is taking another huge step forward in building the power of simulation by offering a smoothed-particle hydrodynamic (SPH) tool with a fully coupled SPH-DEM, real shape representation, and multi-GPU support.

Understanding Discrete Element Method

The fundamental working principle of every DEM code is to detect particle collisions and compute the contact force. This is achieved using the soft-sphere method, where particles are rigid, and any deformation at contact is modeled as an overlap.

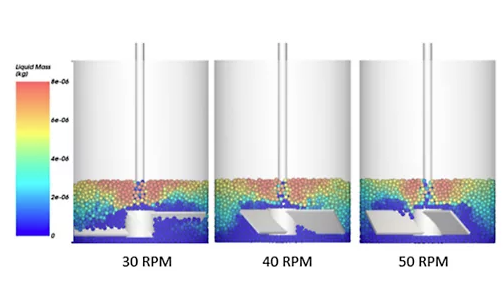

Drying Dynamics of an Agitated Filter Dryer Using Ansys Rocky

Downstream processing of active pharmaceutical ingredients (APIs) involves crystallization, filtration, drying, and milling unit operations. Drying is one of the most energy-intensive unit operations and is often the rate-limiting step in the overall API manufacturing cycle

Ansys Adds Rocky DEM to the Mix, Extending and Enhancing Multiphysics Simulation to Include Particle Dynamics

With the acquisition of Engineering Simulation and Scientific Software Rocky DEM, S.L., which was operated by long-time South American channel partner Engineering Simulation and Scientific Software (ESSS), Ansys adds Rocky DEM to its portfolio. Rocky has been offered by Ansys for almost two years as Ansys Rocky, a partner product, and is already integrated with Ansys flagship software. However, this acquisition will drive even deeper integration.