-

-

July 5, 2025 at 7:03 pm

devashish.wanjari

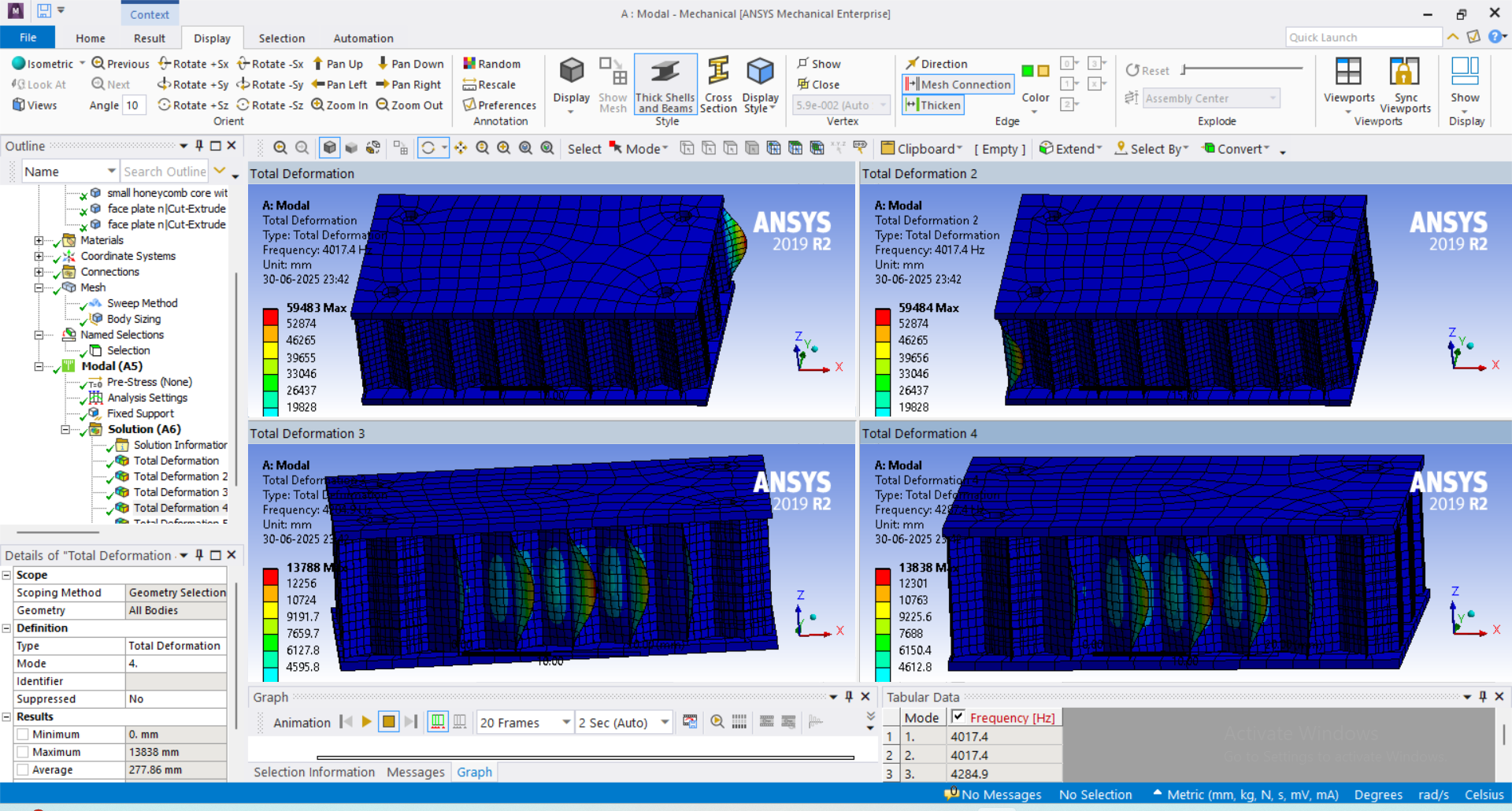

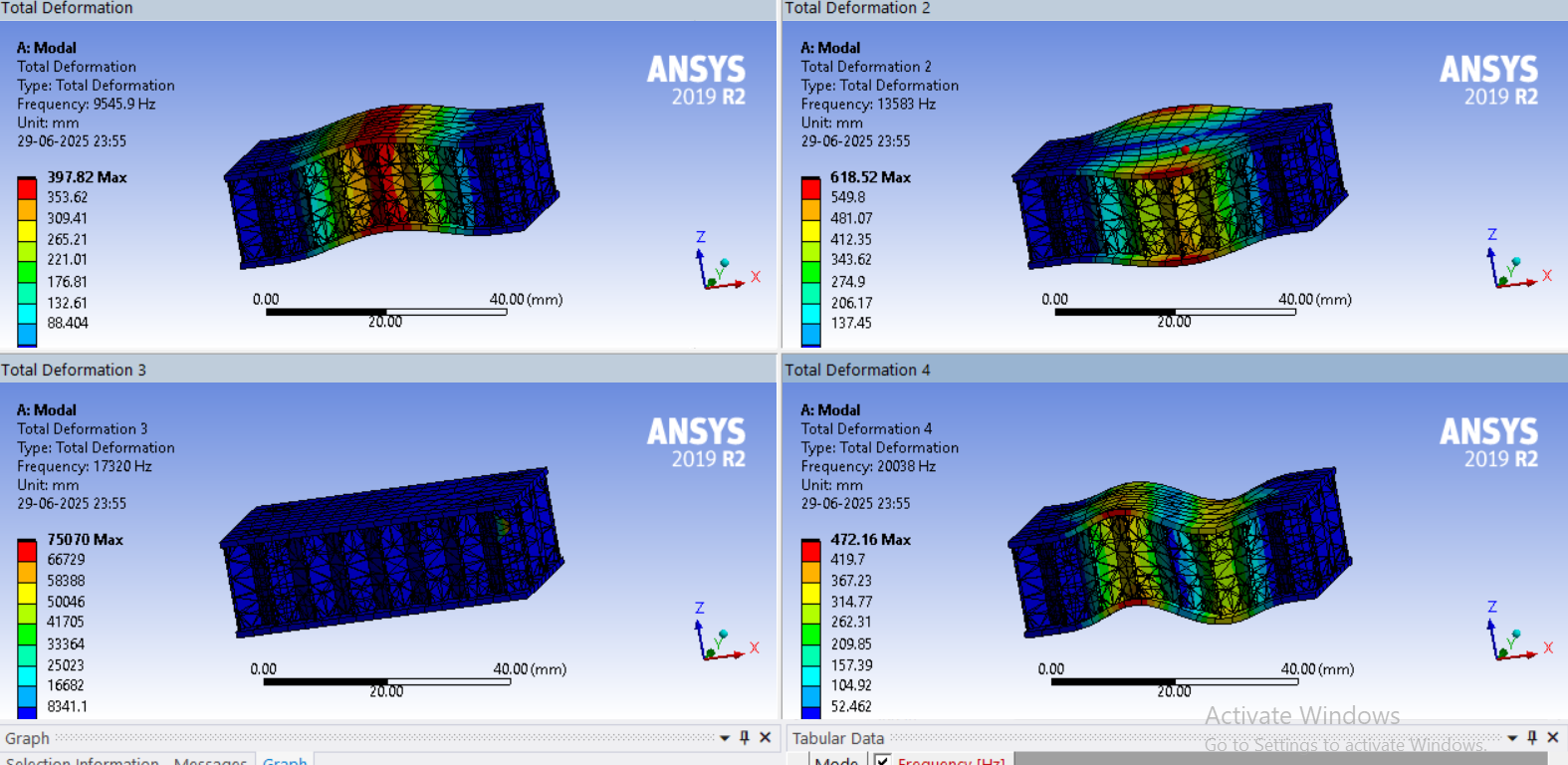

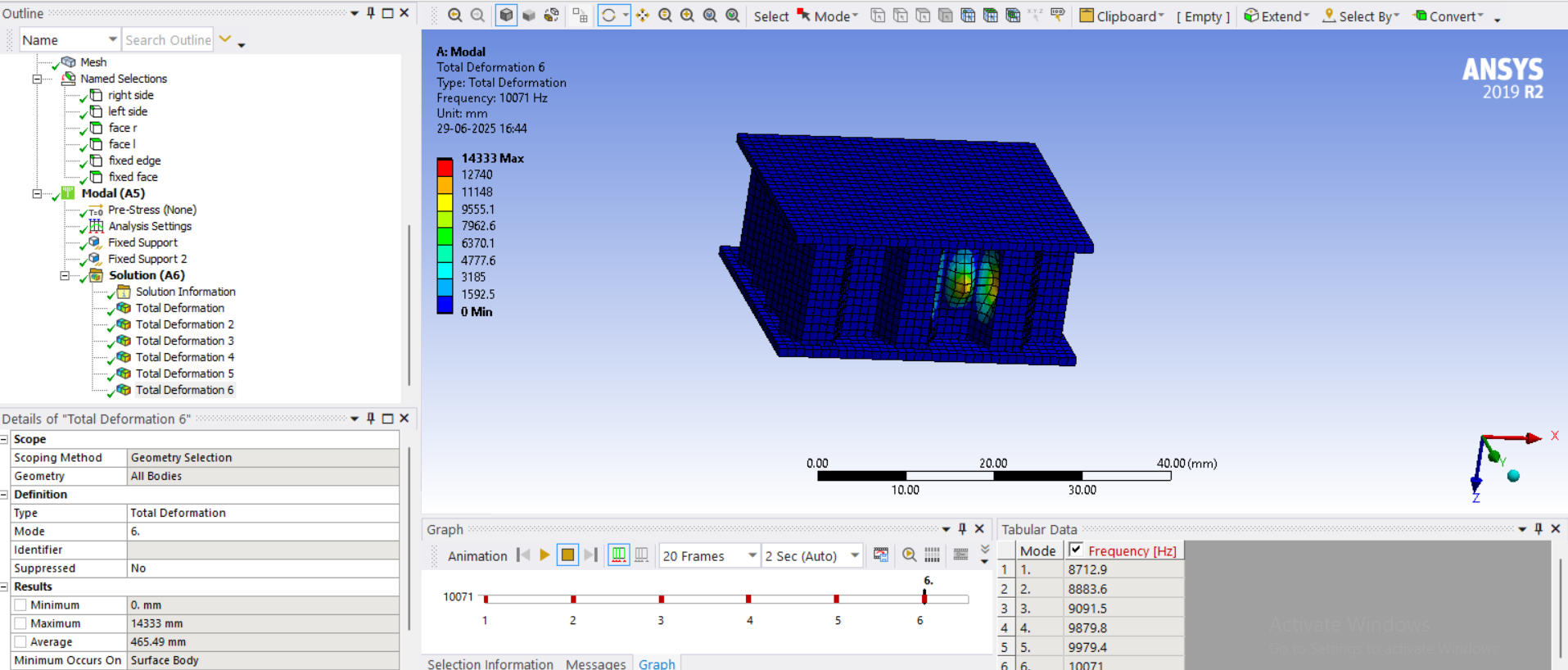

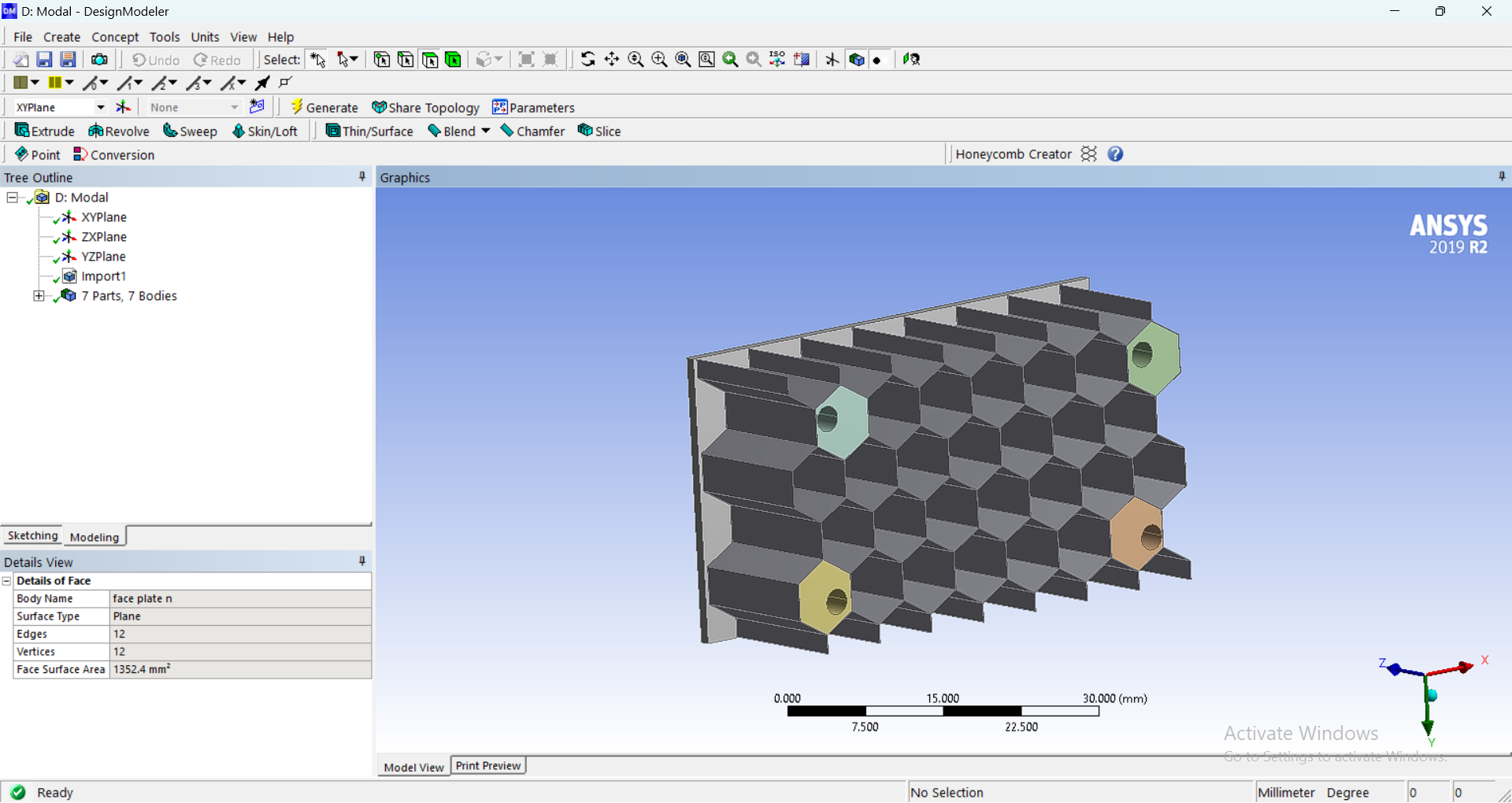

Subscriber**Core Specification:** Cell Size: 6.4 mm, Foil Thickness: 0.025 mm, Material: Aluminium, Cover Plate Material: Aluminium This is the experimental model I am using to simulate the modal analysis of the Honeycomb Sandwich Panel. Currently, I am facing an issue where, when using default meshing with fixed support boundary conditions applied to the holes, I obtain different mode shape data. Conversely, when I refine the mesh size, setting the core's element size to 1 mm and the cover plate's element size to 2 mm, I find that mode no. 6 exhibits only edge deformation. I suspect that the small foil thickness is introducing errors. After conducting some research to address this problem, I learned that converting the sandwich model into a surface model can be beneficial. I attempted this using two methods: 1. **Mid-Surface Method:** In SpaceClaim, I created a mid-surface and bound the two solid cover sheets (made of aluminium) using a manual contact region. I then applied the boundary conditions. However, this approach resulted in only the core edges showing mode shapes, while the cover plates remained stiff, leading to incorrect results. 2. **Honeycomb Creator Extension:** In my second attempt, I used the honeycomb creator extension to model the core and created two surfaces on top to represent the cover sheets. Unfortunately, this method also failed. I am seeking guidance on how to effectively simulate the modal analysis of a honeycomb sandwich panel using a surface model with better mesh quality. It is essential to maintain an accurate representation of the honeycomb core, as I plan to procemessed to optimisation following the modal analysis.

-

July 6, 2025 at 4:39 am

Dennis Chen

SubscriberHello, I assume you have experimental modal analysis results and does that indicate there's no edge-only mode shapes?

If you look at your modal analysis, and you look at the mode shapes with the highest participation factors/modal mass, do you get the mode shapes you expect with the expected natural frequency?

I believe these mode shapes where only an edge has deformation will exist in the modal anlaysis but you should see a very small participation factors. Furthermore, a lot of these modes would be very closely related (very close in natural frequency). In reality, I would question how these mode shapes would be manifested when you do excite the structure in those directions... with added effect of damping as any real life structures would have.

-

- You must be logged in to reply to this topic.

-

3567

-

1103

-

1063

-

1045

-

952

© 2025 Copyright ANSYS, Inc. All rights reserved.

.png)

.png)

.png)