TAGGED: #fluent-#ansys

-

-

August 30, 2025 at 9:34 am

rudraparikh11

SubscriberI am a fresher Mechanical Engineer and this is my first time using a CFD software. Here I am trying to carry out CFD-based thermal analysis of my system using the Realizable k-epsilon turbulence model with scalable wall functions. However, I consistently encounter floating point exception errors during the run. The error sometimes occurs right at the start, and other times after 80–200 iterations. In some cases, the solver reports divergence in energy, temperature, or epsilon.

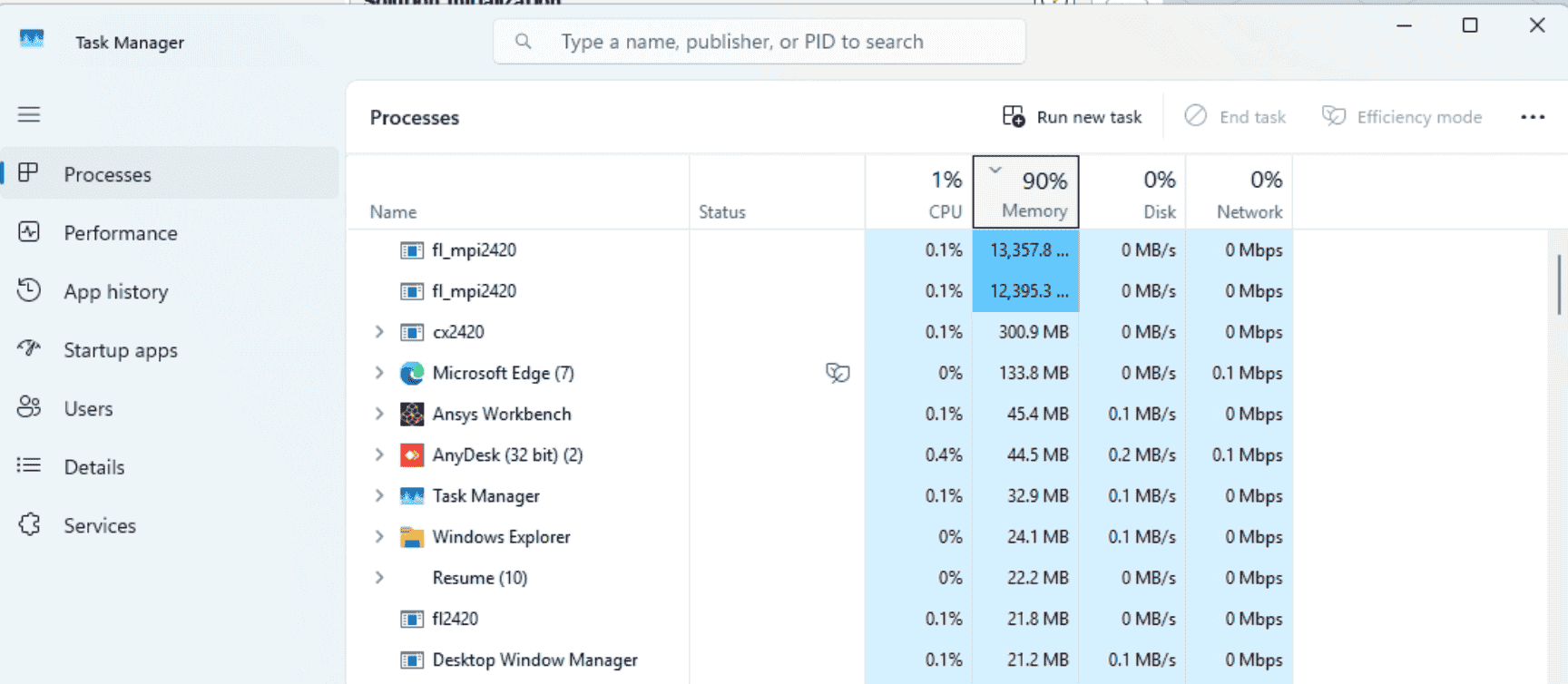

I have already used the Case Check tool, and it reports that my orthogonal mesh quality is within acceptable limits (greater than 0.01). I have also noticed that the solver consumes over 95% of system memory while running, and eventually fails. I am running the simulation with 7 processes, and as a test I also tried running a simplified dummy model with only two components. That case worked smoothly without errors with good speed.

Could the issue be related to high memory usage, or is there some another problem? What would be the recommended approach to resolve this?

If you require any additional details or screenshots from my simulation to better understand the problem please let me know, I will share them if possible. -

September 1, 2025 at 10:55 am

Rob

Forum ModeratorDivergence tends to be mesh or settings related. I'd question any mesh that has worst ortho cell under about 0.1 and wouldn't generally even bother trying with anything under 0.05 without significant checks on where those cell were. Unfortunately, cell quality also only shows that, the mesh quality also needs to take geometry and gradient resolution into account.

Fluent will take as much RAM as it needs. As long as you have 3-4GB per 1M cells it should be fine. How big a model have you created?

For the divergence have a look at the flow field to see what's going on before the solver fails. You're looking for non-physical results and/or "odd" flow features. Plotting contours with node values off may help as that can highlight regions where you've not resolved the flow gradients.

-

September 1, 2025 at 11:47 am

rudraparikh11

SubscriberHello Rob,

Thank you for your insights.

Regarding the mesh quality, I have tried appying body, face and edge sizing to the critical components and geometry however, I am not able to increase the ortho mesh quality above 0.07. I currently have about 1GB RAM per 1M cells, but when I tried decreasing the no. of cells - it further degeraded the quality.

The size of the model is 1500 Kb and it consist about 15 components with 5 different materials including a heat sink which has lots of thin fins.

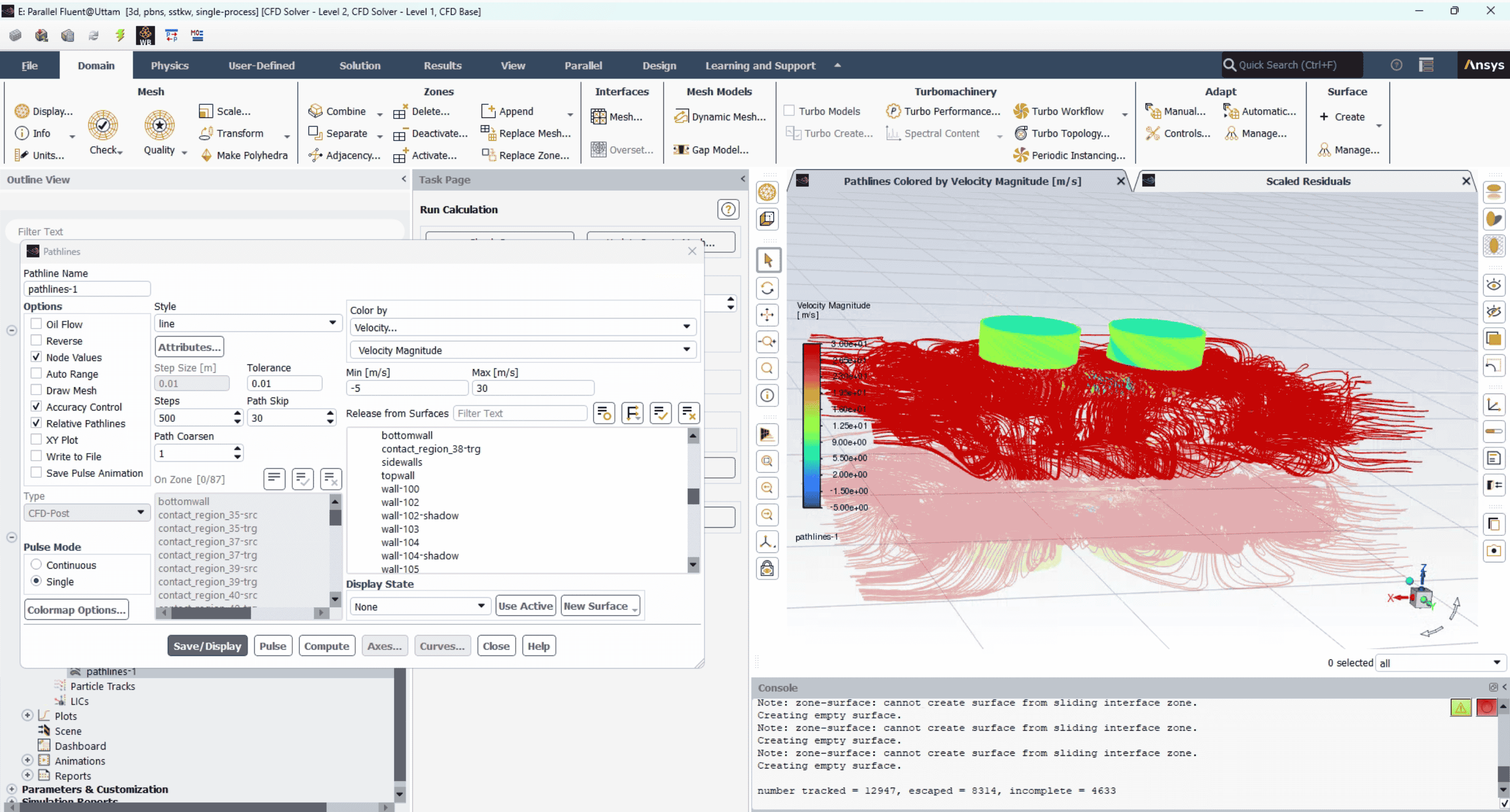

I have noticed some non-physical irregularities in the flow paths. While I don't have the screenshots of the flow path of the current results I am sharing you an image of another simulation which is encountering similar issue. As you can see in the last image the air from 2 fluid domains located at the top (whose interiors are set to fan) is not flowing properly to the rest of the cell zones. These cell zones are seperated by a fluid wall. Another thing is that I am getting extreme temperature ranges in the result (from -273K to 5000K, but I have set initial condition to 300K).

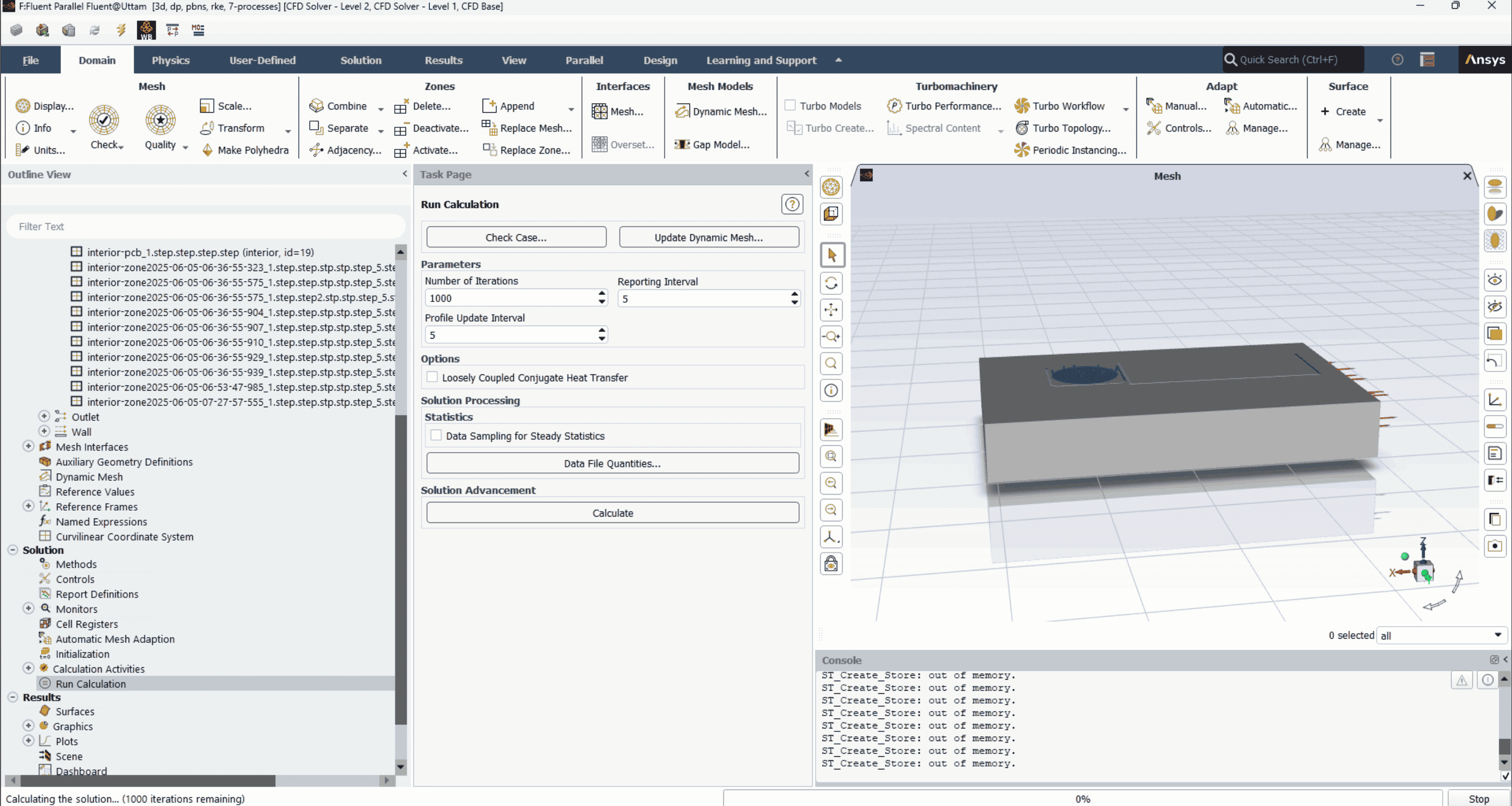

And now I am not able to carry out any simulation because when I try to initialize the solution I get a "out of storage" message and the software crashes. I have also noticed that 2 of the process you see in the image which is taking up 25GB storage, which is not the case earlier. -

September 1, 2025 at 12:59 pm

rudraparikh11

SubscriberOkay, I will try to resolve the geometry as much as I can. I will let you know if I face problems in applying Shell conduction to thin walls.

Thank you for your help!

-

-

September 1, 2025 at 12:50 pm

Rob

Forum ModeratorThe error you've posted is showing you're out of RAM. 1M cells won't fit on 1GB any more, you may scrape through with a little more RAM and SIMPLE but it's unlikely. So, either reduce the cell count or find a bigger computer.

Look where the poor cells are, and also where you're struggling for resolution. Look for what geometry features don't matter: ie if you have thin plates don't use a solid zone but instead use a "thin wall" and potentially Shell Conduction so you can remove these features. Similarly chamfers tend to be removed in CFD. Then look at meshing methods to optimise the use of cells: you need to resolve some parts but maybe not so much elsewhere.

CFD has got a lot easier in the last 30 years. However it's still not as easy as some would hope!

-

- You must be logged in to reply to this topic.

-

3822

-

1388

-

1188

-

1100

-

1015

© 2025 Copyright ANSYS, Inc. All rights reserved.