-

-

November 13, 2025 at 11:24 am

a.kanthale

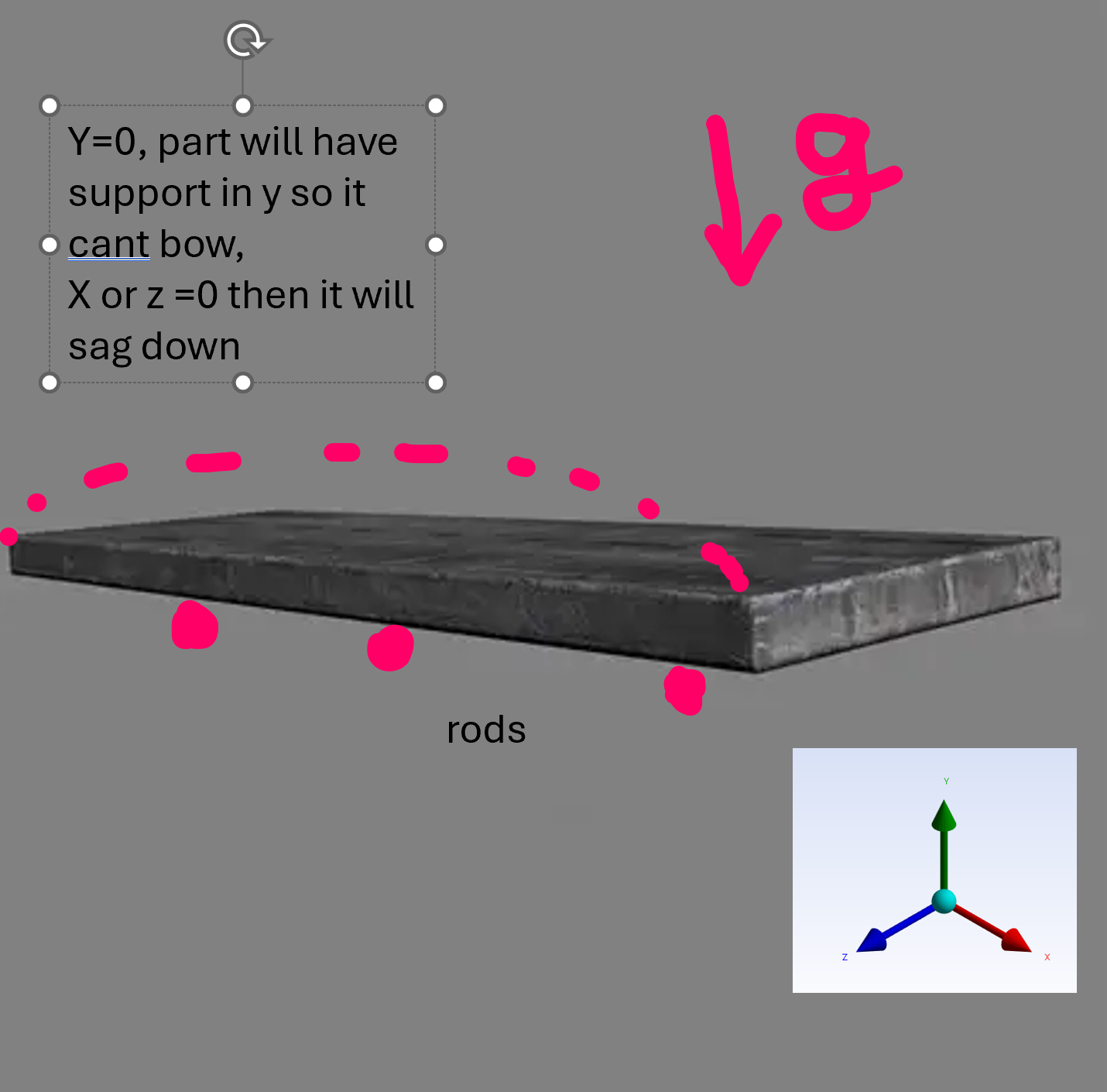

SubscriberI’m currently working on a thermo-structural simulation of a part that cools down from a high temperature to room temperature. The geometry is supported on rods during cooling. Initially, I tried solving the problem using the standard 3-2-1 constraint technique, which worked fine. However, since the part rests on rods, their effect needs to be considered because they prevent the part from bowing downward.

Due to tight deadlines and to avoid additional complexity, I can’t model the rods explicitly. Instead, I applied compression-only supports at the contact faces where the rods touch the part. I’ve tried various approaches, including adjusting time stepping and substeps, but the solution is not converging.

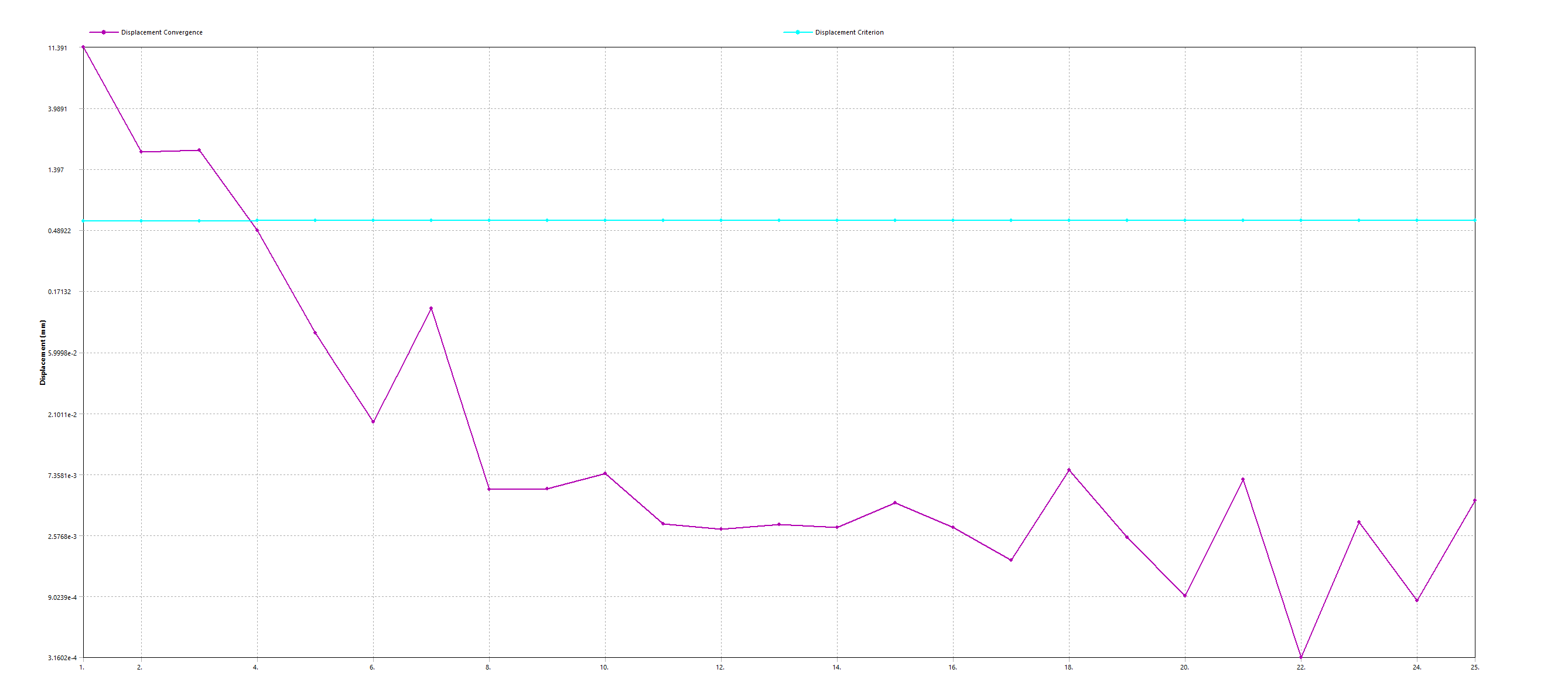

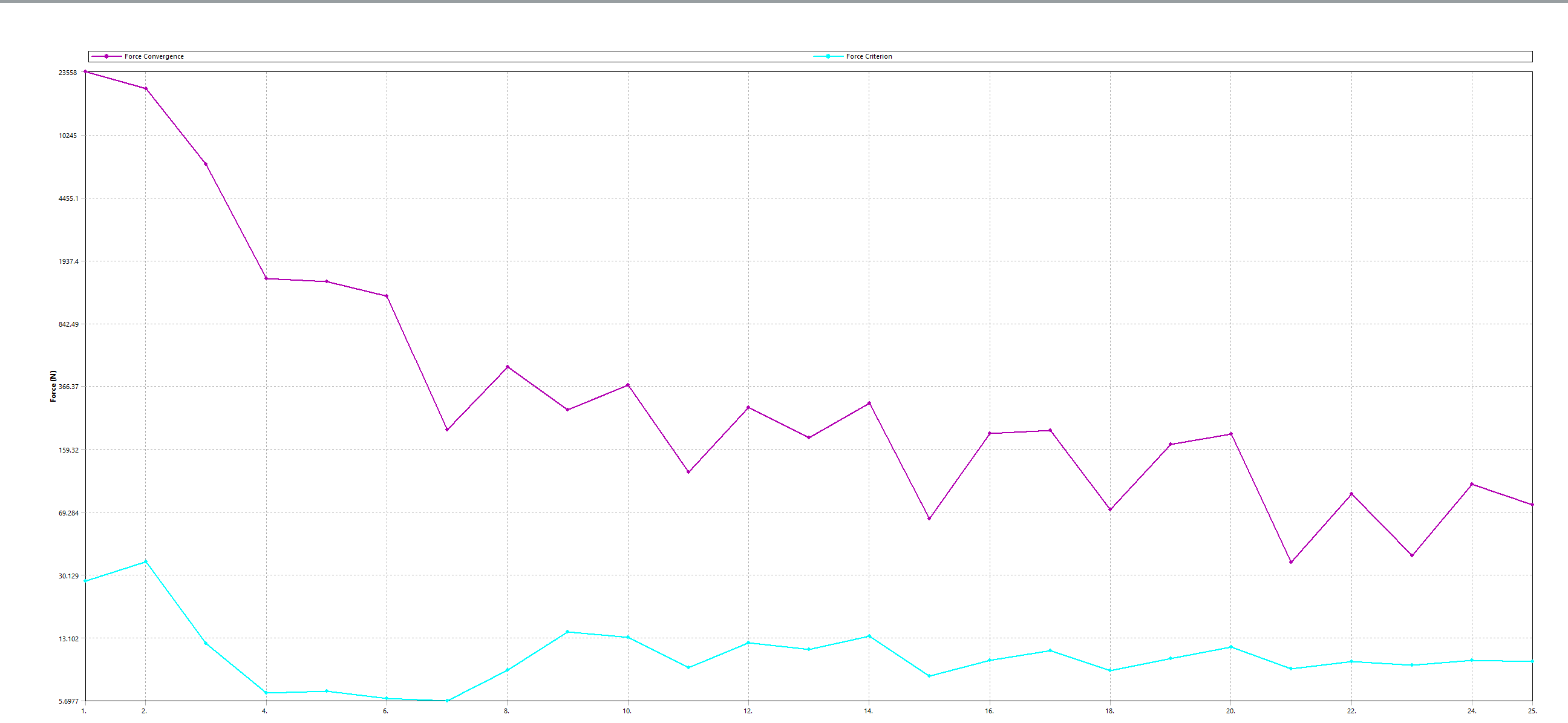

I also plotted the Newton-Raphson convergence graph to identify the issue and refined the mesh, but nothing seems to work. Has anyone encountered a similar problem or have suggestions on how to resolve this?

-

November 13, 2025 at 2:21 pm

Gary_S

Ansys EmployeeIn the Compression Only support, try setting the Normal Stiffness to Manual, and give a value of 0.05.

-

November 13, 2025 at 2:31 pm

Giorgos Papa

Forum ModeratorHello,

have you tried using more sub-steps per loadstep? I do not see any bi-sections in these pics.

Also if the .out file predicts a convergence in more than 25 iterations (which is the default limit) you can increase the iterations by using the NEQIT,50 command (increasing number of equil iterations from 25 to 50 as an example).

Even if you use compression only supports, if you have not defined constrains in other directions, the model could find difficulty to converge (especially for the first substep) due to it being underconstrained. In this case consider using some more boundary conditions to fully constrain your model.

Some examples to consider: Frictionless support, Weak Springs, use some Stabilization.

Kind Regards,

Giorgos

-

November 13, 2025 at 9:59 pm

mjmiddle

Ansys EmployeeJust to add a little more to the posts of Gary and Giorgos, make sure that auto time stepping is on. The normal stiffness Gary recommend of 0.05 is a good first guess. You only want to go as low as you need for it to converge because lowering the contact normal stiffness (compression only support is a contact) affects the contact behavior in ways that are not realistic. It allows more penetration, which increases the face area in contact and lowers the contact pressure. For your gravity loaded part you are probably interested in the part deformation as it cools, so you might not care much about these contact results. So the greater penetration may be alright in this case.

-

- You must be logged in to reply to this topic.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Convergence error in modal analysis

- APDL, memory, solid

- Meaning of the error

- How to model a bimodular material in Mechanical

- Simulate a fan on the end of shaft

- Nonlinear load cases combinations

- Real Life Example of a non-symmetric eigenvalue problem

- How can the results of Pressures and Motions for all elements be obtained?

- Contact stiffness too big

-

4177

-

1488

-

1363

-

1195

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.