TAGGED: ansys-apdl, ansys-contact, apdl, Contact Method

-

-

June 25, 2025 at 7:29 pm

vighnesh.nandavar

SubscriberI am performing a contact analysis of a small plunger pressing against a 10mm plate (have simplified my model to a 10mm square bar for now) and I am not defining any force, rather giving displacement to the plunger to touch the plate.

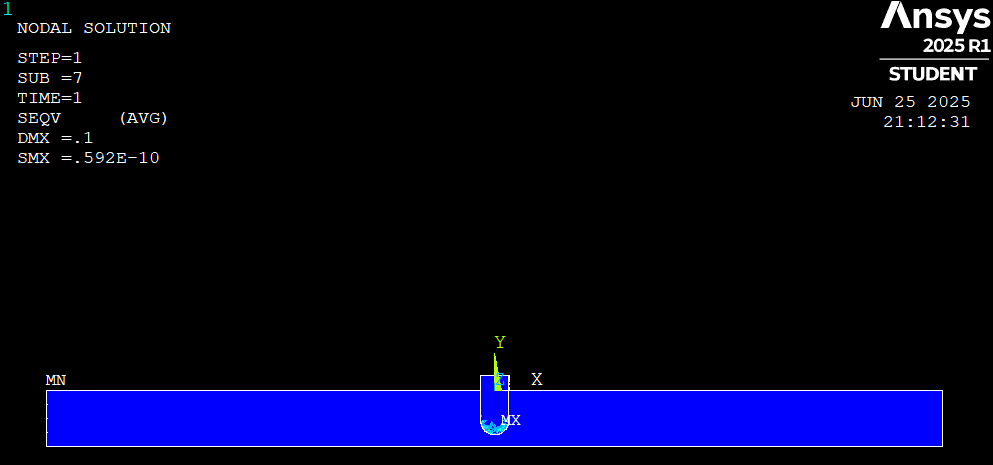

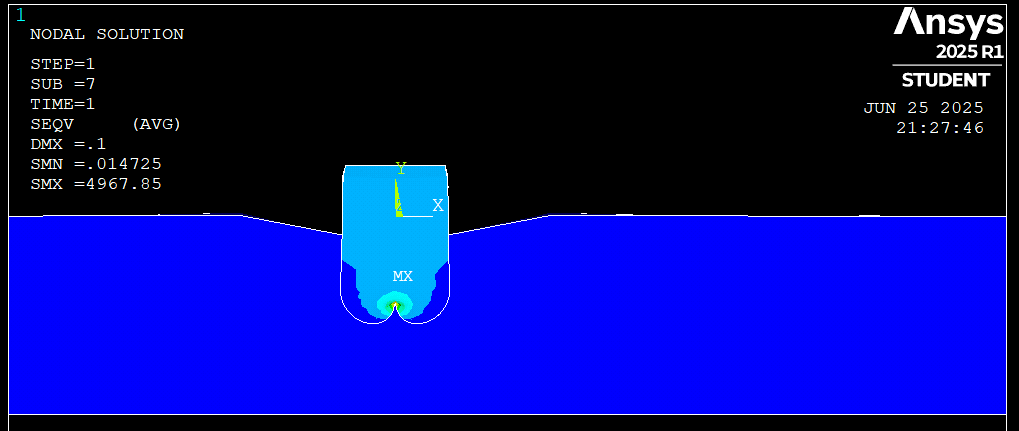

After my analysis, the plunger goes direct inside the plate defying the contact inputs.

There is a gap 0f 0.1mm between two bodies. For the plunger , I have given displacement in Y as -0.1 on the nodes present on the top most surface of the plunger.

What more ?! I am super confused why the plunger is displacing roughly 8mm down.

The following are the contact details I have given:

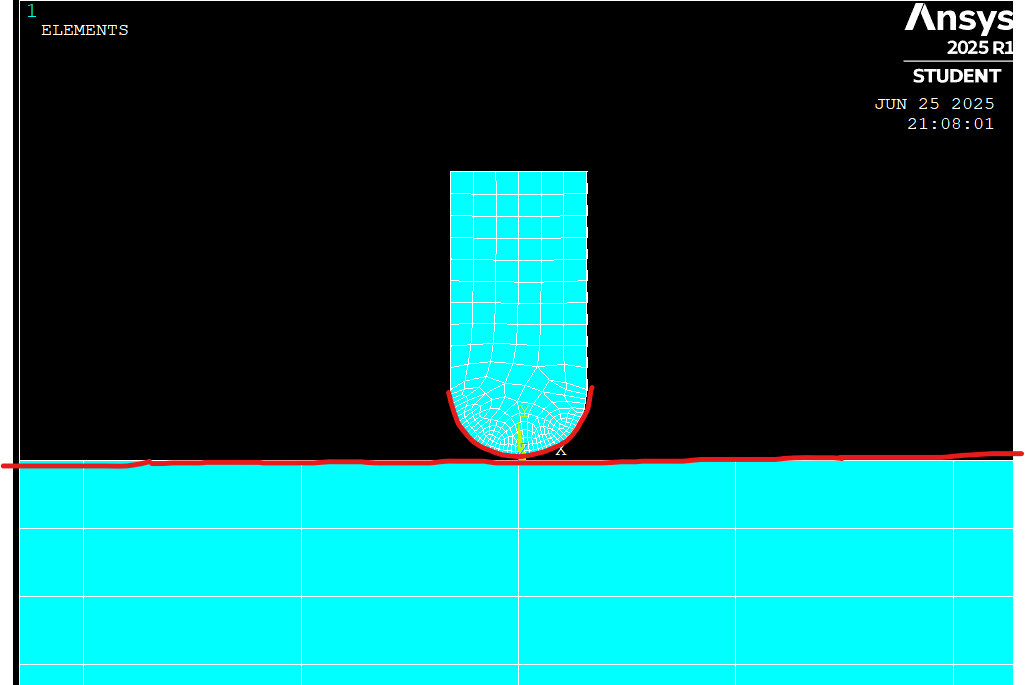

The image indicates red lines. Those are the contact and target surfaces. Well, I have chosen the nodes on these surfaces. I have chosen the contact algorithm to be Augmented Lagrange since its a combo of Penalty and Lagrange. For contact detection, "On nodes-Surface project" because I would like to cast the nodes on to the surface. I have not given any initial penetration since there is a fixed gap of 0.1mm between both bodies. Also the friction coeff for both are 0.

My guess is that I have made a mistake in chosing the contact parameters.

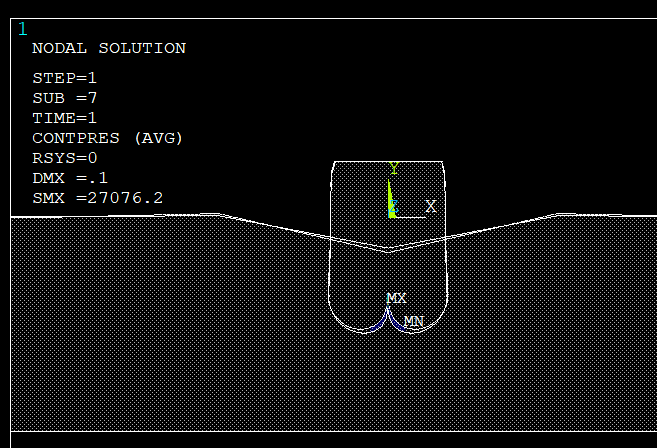

One more, when I try to give a contact offset of 0.1, the following thing happens which I wonder why

Insights on this much appreciated :) -

June 26, 2025 at 1:49 pm

Erik Kostson

Ansys EmployeeHi

See our help manual where there are many apdl examples related to contacts analysis.

https://ansyshelp.ansys.com/public/account/secured?returnurl=/Views/Secured/corp/v251/en/ans_vm/Hlp_V_CH1_IDXELEMNUM.html

See also the help manual for the traget and contact element settings.

Finally use many substeps (NSUBST) so contact can be detected and to aid convergence.

(NLGEOM,ON also)

If you would like to model this in Mechanical workbench, then see our free courses in contact analysis using WB mechanical.

See the VM apdl examples we have that are similar.

All the best

Erik

-

June 26, 2025 at 7:10 pm

vighnesh.nandavar

SubscriberHi Eric,

Thank you for the information bundle. Let me go through it and get back with an update on this thread.

-

-

June 27, 2025 at 4:56 am

mjmiddle

Ansys EmployeeAdding my two cents:

- Contacts work best with similar element sizes on both sides. While the target side can have larger elements in some setups, such as sliding, your "target" elements are many times the size of the elements on the plunger side, which I assume is your "contact" side. If not, it should be.

- As Erik Kostson wrote, you will need small time steps. You need to make sure time steps are small enough to capture the instant of contact within the pinball radius to detect contact. You may think just increasing the pinball radius woud allow this with larger time steps, and it can help a little, but it's most important to use a small time step to get that contact instant. Using a large pinball radius can have some strange effects such as contact occuring and bodies deforming while a gap is mainatined between bodies. Also, you wrote that you set a contact offset of 0.1, and this model does not look appropriate for any offset prescribed.

-

- You must be logged in to reply to this topic.

-

3367

-

1050

-

1047

-

886

-

837

© 2025 Copyright ANSYS, Inc. All rights reserved.