-

-

May 19, 2025 at 7:35 pm

lxk4451

SubscriberHello,

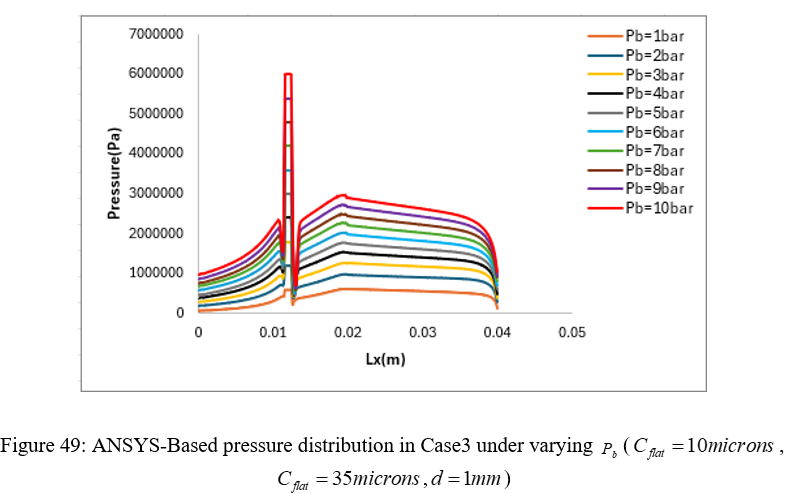

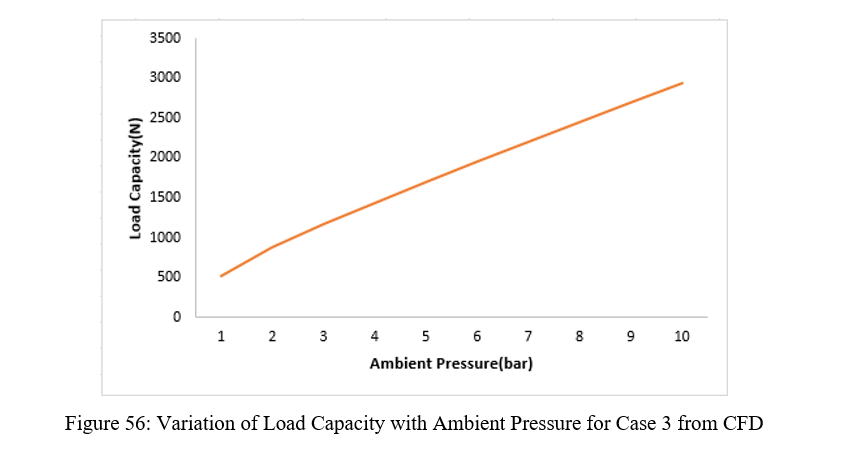

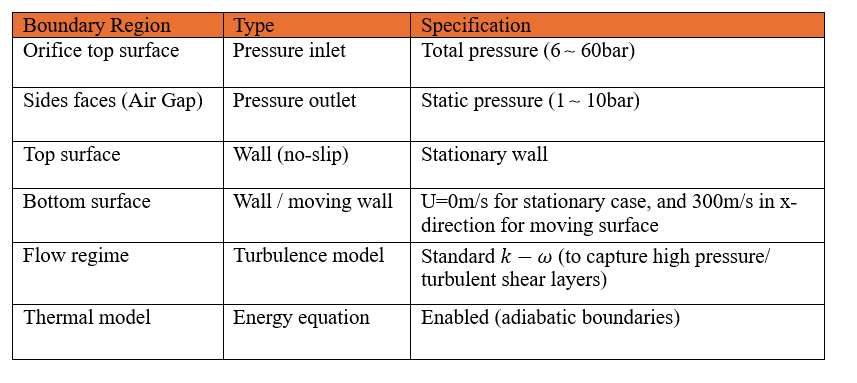

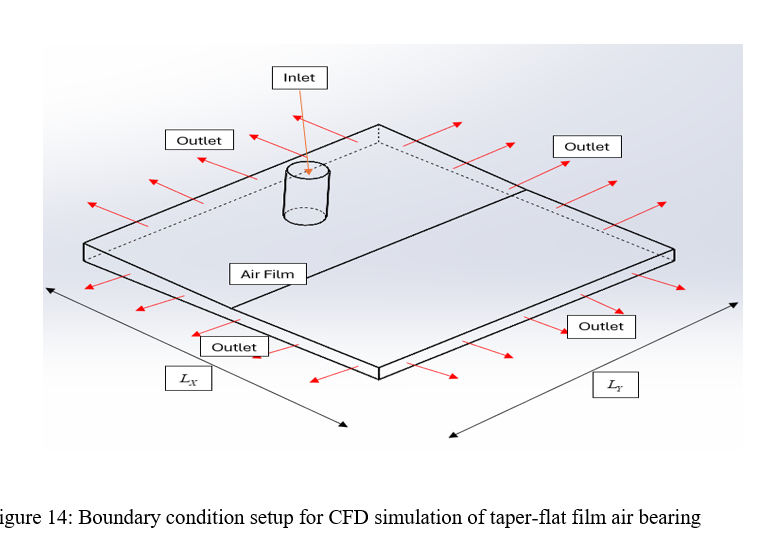

I am doing CFD analysis for taper-flat film hybrid air bearings. The above attached graphs are for taper-flat thin air flim with moving surface spped of 300m/s. i am seeing there is a huge pressure drop(flow mach is greater than 1) at orifice curtain which is less than the outlet pressure and my load capacity is weired compared with pressure graph. I am using pressure-based solver and facing some issues like temperature limited error, and reversed flow. why is it happening and could anyone give me some tips to solve it?

Thank You.

Regards,

Lokesh

-

May 20, 2025 at 8:53 am

Rob

Forum ModeratorStart with a velocity boundary and get the flow looking right and then monitor pressure. The "logical" solution is air flows into the gap and then towards the outlet surfaces: that won't be uniform. But as the solution evolves the may be other options that are theoretically stable for a brief period so Fluent may take time to settle.

I assume you're using ideal gas for density?

A 10micron gap is small, and will be approaching the limits of the continuum assumption and numerical tolerance. Physical surface roughness will also become non trivial and "weird things" (misquoting one of the Stamford Profs for politeness) begin to happen.

-

May 21, 2025 at 1:05 am

lxk4451

SubscriberYes, I am using ideal gas and But my pressure and load capacity graphs are incorrect when compared both why? could you confirm whether the load capacity is corrcet compared to the pressure values from the above figures?

Thank you.

-

May 21, 2025 at 8:38 am

Rob

Forum ModeratorI can't confirm anything from those graphs as I have no idea what they are based on. Nor do I know how much mesh is in the gap, the aspect ratio and level of convergence. Given the consistency of the various curves (no jumps, progression is logical) what ever isn't agreeing with your expectation looks to be a reasonable result: I assume you've checked your modelling exactly what was in the experiment?

-

- You must be logged in to reply to this topic.

-

3145

-

1007

-

935

-

858

-

792

© 2025 Copyright ANSYS, Inc. All rights reserved.