Problem Specification — Lesson 1

A simply supported beam of rectangular cross-section is point loaded at some arbitrary point along its length as shown in figure below.

P = 10,000 lb, L = 100 in, a = 75 in, b = 3 in, h = 8 in

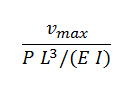

The material is structural steel with Young's modulus E= 2.9e7 psi and Poisson's ratio of 0.3. Using Ansys Mechanical, find the finite-element solution for non-dimensionalized maximum deflection defined as:

Compare the finite-element solution for plane stress and plane strain to Euler-Bernoulli beam theory. Discuss the comparison between the finite-element and beam theory results. Note that the non-dimensionalized maximum deflection is independent of the Young's modulus.

Learning Goals

The purpose of this tutorial is to showcase how the assumptions of planar behavior affect the results of analyses in simple beam bending. The plane stress and plane strain assumptions lead to bounds on the actual three-dimensional behavior, yet this deceivingly simple analysis is not so readily validated by beginners who are not well-versed in the reasonable application of planar approximations. This analysis culminates in a series of results that can lead the calculation to “converge” on a substantially incorrect result which is inaccurate by over 100%. The point of this exercise is to have students convince themselves that simplified theories are often bounds and that geometries that do not cleanly and unambiguously lend themselves obviously to either (thin or thick) limit, may still be ones for which one limit is reasonable and applicable. Also, an intuitive feel for making and applying these simplifications often eludes beginners. In this way, this tutorial is an exercise in applying caution in interpreting one’s results.