-

-

January 10, 2023 at 5:55 pm

-

January 10, 2023 at 6:46 pm

peteroznewman

SubscriberYou don't say what output you are solving for.

There are a few threads on the forum about simulations to move a heat source spot along a surface. Did you try to search for them using Search field above?

Here is a thread that uses Fluent and a VOF analysis to compute the liquid/solid fraction in each cell. That is a different approach to Kill the elements that you were thinking of.

-

January 10, 2023 at 6:51 pm

hasanilkerceliker

SubscriberI want to analyze myself using the birth and death technique. However, I can't do the required coding. Here I am talking about the loop that writes with pulse number. I want to give a laser flux of 28 J/cm2 to the material and I want to examine the heat dissipation region.

-

January 10, 2023 at 6:57 pm

-

January 10, 2023 at 7:03 pm

peteroznewman

SubscriberIs a crater formed from a single pulse?

Is the spot moved after each single pulse? How far does the spot move?

What is the duty cycle of pulse ON, pulse OFF?

-

January 10, 2023 at 7:23 pm

hasanilkerceliker

SubscriberThe first phase presents the simulation of single-pulse laser paint ablation at the laser fluence ranging from 20 J/cm2 to 50 J/cm2

-

January 10, 2023 at 10:22 pm

-

January 11, 2023 at 12:40 pm

hasanilkerceliker

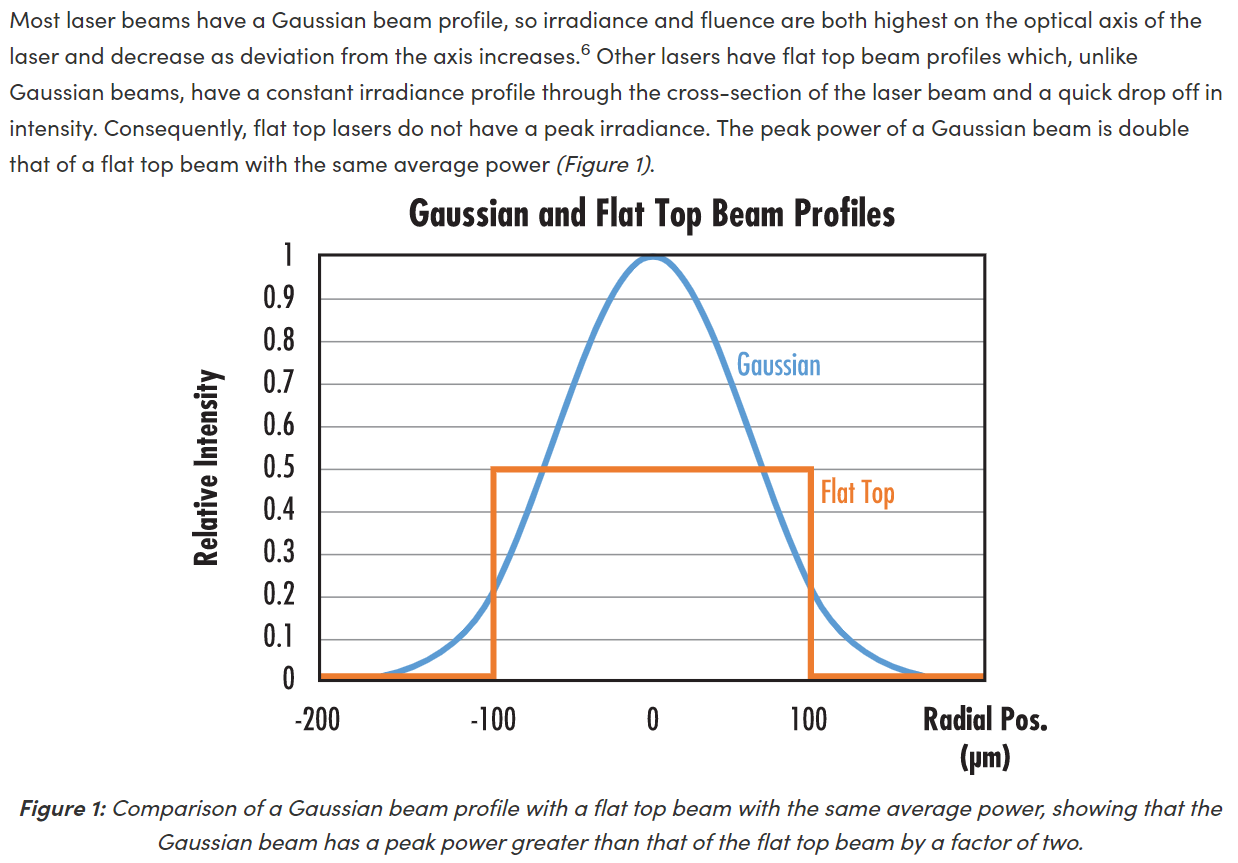

Subscribergauss

-

January 11, 2023 at 4:17 pm

peteroznewman

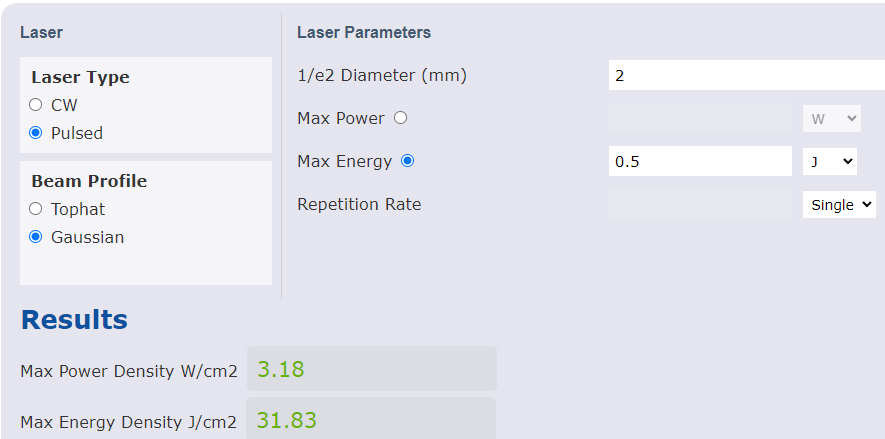

SubscriberOkay, what is the 1/e2 spot diameter?

https://www.ophiropt.com/laser--measurement/power-density-calculator

-

January 11, 2023 at 5:25 pm

hasanilkerceliker

Subscribercan I ask something? Which module is the screenshot from?

-

January 11, 2023 at 5:26 pm

hasanilkerceliker

Subscriberand spot diameter= 60 micrometer

-

January 11, 2023 at 5:35 pm

hasanilkerceliker

SubscriberIf you give me an e-mail address, I would like to send you the analysis I want to work with.

-

January 11, 2023 at 6:55 pm

peteroznewman

SubscriberIn Workbench, use File, Archive to create a .wbpz file. Upload that file to a file sharing site such as Google Drive or OneDrive. Reply with the link to that file then anyone can download it.

-

January 11, 2023 at 7:06 pm

hasanilkerceliker

Subscriberhttps://drive.google.com/drive/u/1/folders/1s02CPkA0h725BAN2tBE5qXhOZqOZbJJy

-

January 11, 2023 at 8:12 pm

peteroznewman

SubscriberThat link does not allow anyone to download the file, it is not public.

-

January 11, 2023 at 8:15 pm

hasanilkerceliker

Subscribermade available

-

January 11, 2023 at 8:27 pm

-

January 11, 2023 at 8:30 pm

hasanilkerceliker

Subscriberhttps://drive.google.com/file/d/15pZklIY2ZLdT33WBajbRnTrEZlf00hkR/view?usp=share_link

https://drive.google.com/file/d/1TLXM07ewH7Cw_1hw9-5hOyVcVIcN4scq/view?usp=share_link

-

January 11, 2023 at 11:14 pm

peteroznewman

SubscriberPlease put the 11.STEP file up on GoogleDrive also.

What version of ANSYS are you using?

-

January 11, 2023 at 11:32 pm

peteroznewman

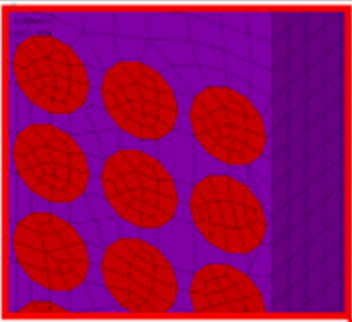

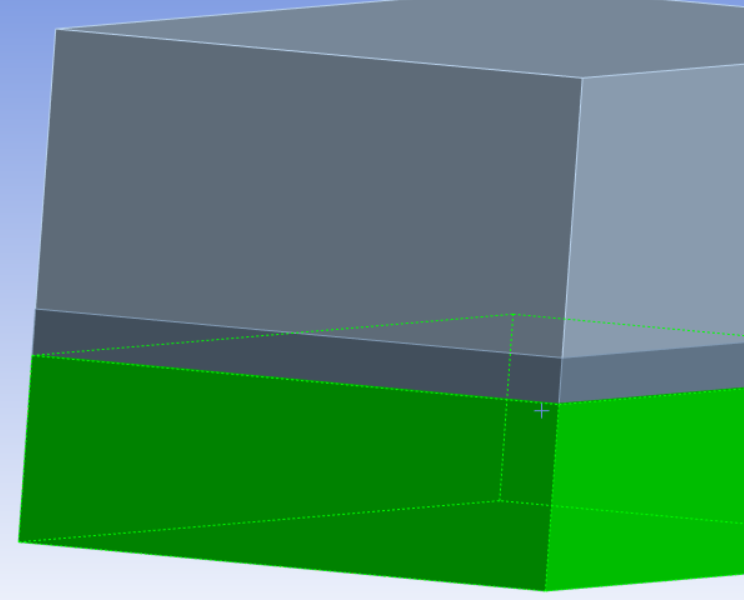

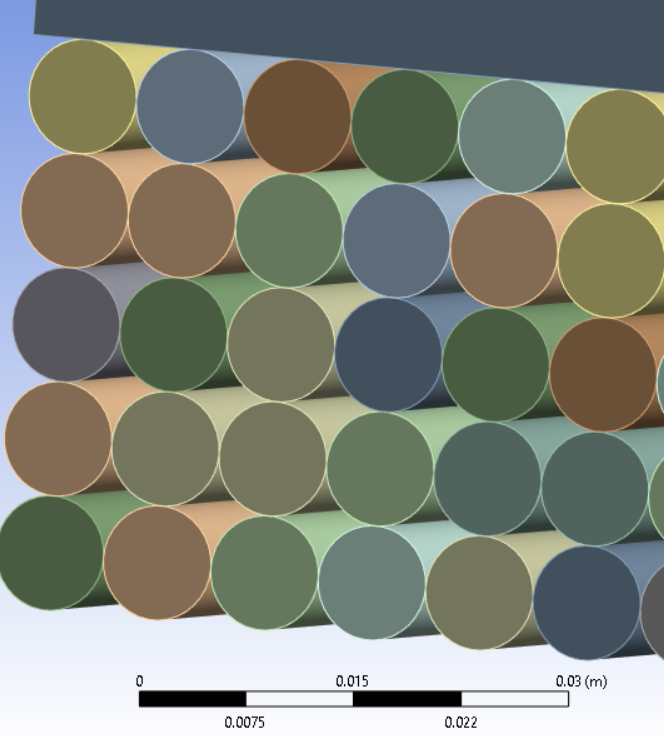

SubscriberFrom the paper, the mesh should look like this...

To get that mesh, you need to have space between the carbon fibers in red. Also, you have to subtract the carbon fibers from the resin block in purple so that the resin block has holes where the carbon fiber fills the holes.

Your resin block has no holes in it.

Your carbon fibers have no space between them.

You need to fix those issues.

-

January 12, 2023 at 10:07 am

hasanilkerceliker

Subscriberthere is a problem there. The measured value given is in micrometers. so very small values are output. When I enter solidworks, it does not accept. The size of the given piece is in micrometers if you have noticed. A length of 120 micrometers is given. That's why I didn't give a space. but I didn't think it would affect the upper part where we give the heat. Does it affect?

-

January 12, 2023 at 12:56 pm

hasanilkerceliker

SubscriberI did the process by renewing the drawing, but it gives an error in the analysis and I can't figure out the reason.

https://drive.google.com/file/d/1ZSN7Yww9vprQWQBbxkxTkziPSKrSN0-M/view?usp=share_link

https://drive.google.com/file/d/17vyyQwVgKORrocvDzM2Gr3H7yK0z8AEF/view?usp=share_link

-

January 12, 2023 at 1:24 pm

peteroznewman

SubscriberDon't use Solidworks to draw carbon fibers. Open SpaceClaim and click on the File, Options menu. On the Units tab, you can change to microns. Then you can draw a circle and type in the diameter in microns. Draw a block for the resin and subtract the fibers to create holes in the resin. Finally, go to the Workbench tab and click the Share button. This will cause the mesh to connect the resin to the fibers. Only SpaceClaim or DesignModeler can create shared topology so you must use one of these. If you only use Solidworks, the model will need to have Bonded Contact and you don't want that. I won't be looking at the models you posted above as they won't have the shared topology that I recommend.

-

January 12, 2023 at 1:29 pm

hasanilkerceliker

Subscriberthank you peteroznewman

-

- The topic ‘Birth and Death’ is closed to new replies.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Convergence error in modal analysis

- APDL, memory, solid

- Meaning of the error

- How to model a bimodular material in Mechanical

- Simulate a fan on the end of shaft

- Nonlinear load cases combinations

- Real Life Example of a non-symmetric eigenvalue problem

- How can the results of Pressures and Motions for all elements be obtained?

- Contact stiffness too big

-

4167

-

1487

-

1363

-

1194

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.