Homework, Quizzes, and Simulation Examples - Thermal Capacitance

Simulation Examples

Several simulation examples are provided here. Each of them comes with a description file, video instruction, and Ansys simulation file. All of the simulations are conducted by Ansys. Download student version of Ansys from here.

(1) Stent Cooling Process

A cardiovascular stent is a medical device to open a plaque-blocked vessel. A commonly used material for stents is Nitinol, a Ni-Ti alloy. A stent during the manufacturing process is annealed and quenched into a specific shape. The annealing process is a heat treatment that keeps the stent under high temperature for a certain time, and the quenching process submerges the stent into a quenchant to cool in at a certain rate. The cooling rate of a stent should be controlled as too slow of cooling rate is inefficient for the manufacturing process, and too fast of cooling rate can increase the brittleness of the stent, cause heat-induced stress and even cracking.

In this simulation, we model the quenching process of an annealed stent, from 400℃ to room temperature (20℃). Two approaches to cooling are compared: water quench and forced air cooling. The difference between these two cooling approaches is the convection speed. Download the zip file and extract the contents. Go through the Readme file. Follow along with the provided How To Video file.

(2) Wood Bench vs. Steel Bench

It is a common impression that a wood bench feels slightly warmer than a steel bench on a cold day. While it is true that the conductivity of steel is higher than wood, which causes heat to escape away faster from our hand when we touch it, which makes the steel bench “feel” colder, it is also true that the specific heat of wood is much higher than steel, and thus for the same weight of wood and steel, wood stores more energy and takes longer to cool when the convection cooling rate is the same.

This example uses simulation to illustrate the idea of specific heat and thermal mass (thermal capacitance) in transient analysis. Three models are created:

- Case 1: A wood bench

- Case 2: A steel bench with the same panel mass as the wood bench

- Case 3: A steel bench with the same panel volume as the wood bench

The surface area of the wood bench panels is made equal to make them comparable in the convection boundary condition. These benches are left on a cold night for 4 hours. Walkthrough the simulation steps and find out the temperature distribution with time and the energy loss in each bench. Download the zip file and extract the contents. Go through the Readme file. Follow along with the provided How To Video file.

(3) Electric iron

As mentioned in the "application of transient thermal analysis" section, this electric iron simulation investigates the heat transfer from electric energy to heat energy. Follow the instructions and find out how the temperature changes in the iron with time. Download the zip file and extract the contents. Go through the Readme file. Follow along with the provided How To Video file.

Homework

The air-cooled engine is common in motorcycles, lawn mowers, generators, etc. It dissipates heat from the engine through air circulation. The design of metal fins increases the surface area of the engine and thus improves the cooling rate through convection. The design of the air-cooled engine involves many aspects of engineering considerations, such as cooling rate, total mass, geometry restrictions, and so on.

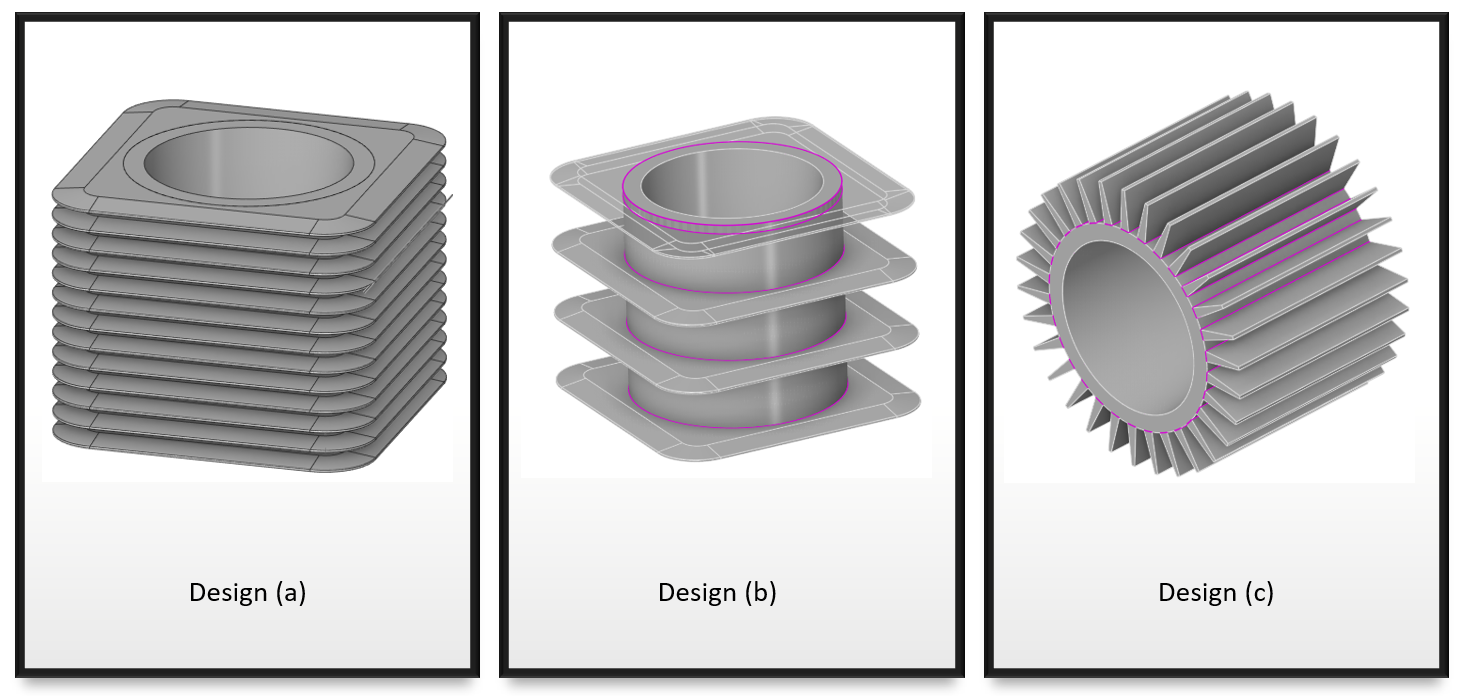

This homework isolates variables and greatly simplifies an engine design so that one only needs to focus on the heat transfer aspect. A simplified geometry is used that contains an engine cylinder and multiple heat-dissipating fins. Follow the instructions below and answer the questions:

1. Conduct a transient heat analysis on Design (a) and Design (b), and compare the time it takes to cool the maximum temperature of the engine cylinder down to 35℃. The modeling details are listed below:

Structural steel is used on both the engine cylinder and the metal fins. The boundary conditions are defined as follows: the cylinder’s initial temperature is set to 120℃ while the bulk temperature outside of the fins is set to 22℃; a convection boundary condition is applied to the outside surface of the cylinder and the fins with the ambient temperature as 22℃, and the convection coefficient as 1000W/(m2∙℃).

2. Conduct a transient heat analysis on Design (c) with the same modeling details in Step(1), and find out the time it takes design (c) to cool the maximum temperature of the engine cylinder down to 35℃. Assuming there are two design criteria:

a. The maximum temperature of the engine cylinder should drop to 35℃ within 50 secs.

b. Minimize the total mass.

Which of the design is better? Design(a), (b), or (c)?

Download the zip file and extract the contents. Go through the Readme file. Follow along with the provided How To Video file.