Topology Optimization of a Bell Crank - Lesson 1

Bell crank used in suspension has two arms connected to a common pivot. They transfer motion between two parts meeting at an angle, essentially changing the direction of the applied force.

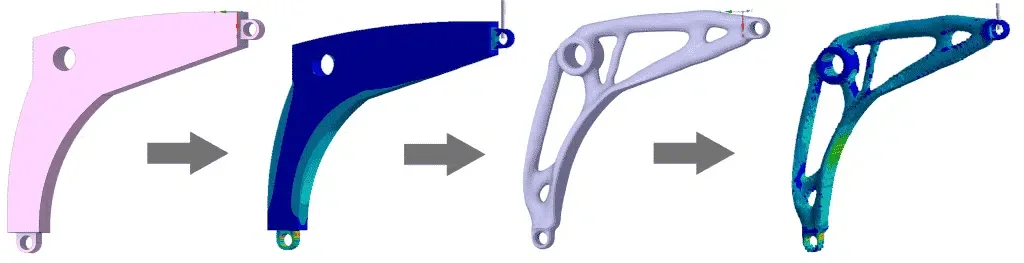

In this lesson, we will first conduct static structural analysis to understand the value and location of stresses on the component and then use the topology optimization method to cut down the material in low-stress areas.

In this video, you will learn how to carry out a structural analysis of a bell crank applying forces and boundary conditions (BCs) and get the results ready for topology optimization.

Download the simulation files here to follow this lesson.

The following video shows the process of reducing component weight while maintaining strength using the topology optimization method and carrying out design validation of optimized geometry.